A D V A N C E D M A T E R I A L S & P R O C E S S E S | S E P T E M B E R 2 0 1 6

1 8

function of spatially related applied or

residual stress conditions can directly

measure d-spacing of an imaged sam-

ple over the entire view area with single

pixel size defining the gauge volume,

leading to potentially increased spatial

resolution of the strain maps.

Using neutrons to image residual

stress enables nondestructive pene-

tration deep into large components.

Hard (high energy) x-rays offer similar

penetration capability (depending on

the material), but the relevant diffrac-

tion angles are very small, so gauge

volumes are needle-like, which is prob-

lematic for measuring one component

of the stress. Therefore, the two tech-

niques are highly complementary and

are increasingly used in combination.

A limitation of the residual stress and

Bragg-edge imaging techniques is the

ability to time-stamp neutrons at a

very high temporal resolution to pro-

vide a mechanism to detect Bragg

shifts. Analysis of the imaging pattern

using single Bragg peak fit or full pat-

tern Rietveld refinement gives an accu-

rate value for the interplanar spacing,

d

hkl

, fromwhich the lattice strain,

ε

, can

be determined by:

(5)

where

d

0

is the reference interplanar

spacing under stress-free conditions.

For tensile strain,

d

hkl

is greater than

d

0

,

which means the Bragg’s peak shifts to

a smaller angle; for compressive strain,

d

hkl

is smaller than

d

0

.

PUTTING NCT TO WORK

A 70-mm-tall Inconel 718 turbine

blade made by AM was measured using

nCT at the high flux isotope reactor

(HFIR) CG-1D neutron imaging beam-

line at ORNL

[13]

. Figure 1a shows the

blade’s rendered volume obtained from

nCT using fake coloring. Virtual studies

can be performed on a selected sec-

tion of the part (Fig. 1b) or on a slice-

by-slice basis (Fig. 1c). Figure 1c shows

the nCT attenuation slice in gray scale

overlapped with the outline of the

component (in yellow) from the engi-

neering drawing from which the part

was printed. This direct comparison

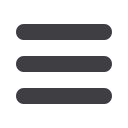

Fig. 1 —

Examination of AM Inconel 718 turbine blade using neutron computed tomography:

(a) nCT rendered volume; (b) virtual section from yellow outlined area in nCT data; (c) engineer-

ing drawing contours (yellow) overlapping neutron slice (gray); (d) color map of blade internal

structure shows variance from engineering drawing (purple and pink).

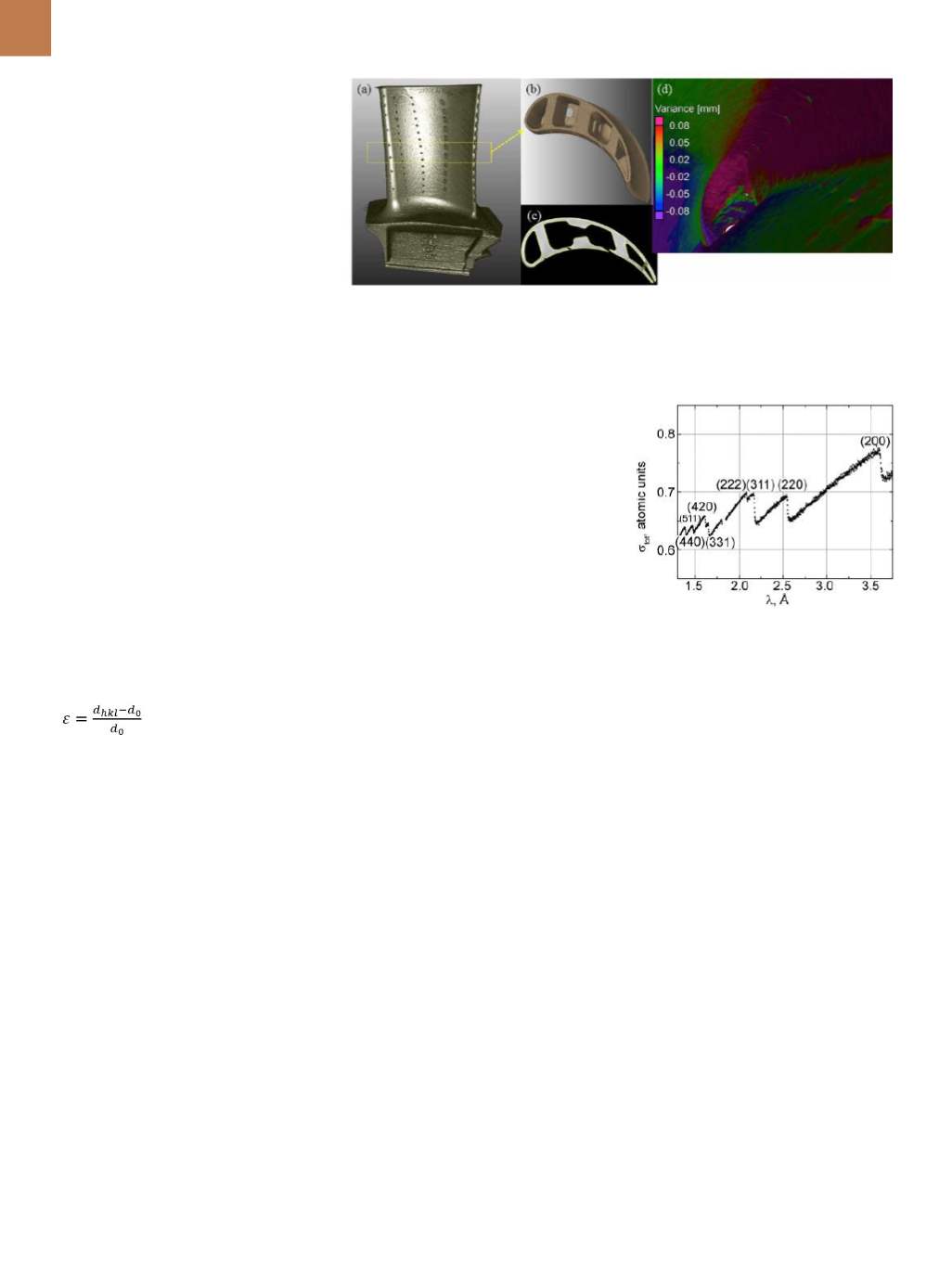

Fig. 2 —

Total neutron cross section as a

function of wavelength for Inconel 718 powder.

Increase of statistical noise at higher wave-

lengths is due to the decrease of neutron flux at

these wavelengths. The gap between (311) and

(222) is due to a detector acquisition time-out.

can be performed for the complete vol-

ume. Overlapping the outline virtually

enables various nondestructive mea-

surements including:

• Dimensional accuracy (printing

tolerance)

• Distortion (Fig. 1c)

• Defects and surface roughness of

internal structure not reachable

using conventional characterization

techniques without cutting (Fig. 1d)

• Porosity

Figure 1d also shows an inter-

nal air path with acceptable deviation

(

±

0.08 mm) from the engineering draw-

ing (indicated from red to blue), and

outside tolerance (indicated in pink and

purple). A shift of the channel walls (in

pink and purple) may have occurred

due to the part relaxing after printing.

A video of the overlap of the turbine

blade design and nCT is available at

https://youtube.com/watch?v=eLTJl-bqICno&feature=youtu.be.

The study is done systemati-

cally at the resolution capability of

the neutron imaging system (50

µ

m in

this case), and is fed back to model-

ing capabilities to optimize printing

parameters. In particular, areas of

material removal and surplus can be

tracked down throughout the sample

volume, including internal structures

(Fig. 1c). In addition, it is possible

to directly measure the evolution of

defects by measuring a standard sam-

ple before and after removal of the

build plate and overlapping nCT scans.

Figure 2 illustrates the Inconel 718

powder Bragg edges (equivalent to a

nontextured sample) measured at the

SNS Vulcan diffractometer. Edges are

sharp (as expected for a powder sam-

ple that has no preferred grain orien-

tation), and their respective positions

correspond to theoretical Bragg edge

values calculated using d-spacing (

d

=

3.595 Å) of Inconel 718 at the SNS Vul-

can beamline. Powder data represent

the ideal case and Bragg edge is drasti-

cally altered in a textured sample with a

grain size distribution.

Bulk samples were prepared from

the Inconel powder mentioned previ-

ously using electron beam melting at

the ORNL Manufacturing Demonstra-

tion Facility. Samples were fabricated

while manipulating the electron beam

to form a real melt, which resulted in

solidification of grains in a random

manner. Figure 3a shows a represen-

tative electron back scatter diffraction