A D V A N C E D M A T E R I A L S & P R O C E S S E S | S E P T E M B E R 2 0 1 6

2 2

zation field has seen XRF technology

evolve and even match OES in terms of

performance and reliability. XRF is now

incorporated into much smaller instru-

mentation than ever before, allowing

easier access to hard-to-reach areas

such as corner welds, inside vessels

and exchangers. Inherent to its smaller,

lightweight design, it can also help

reduce operator fatigue.

How is XRF technology used in plants

and refineries?

The greatest advantage of XRF

technology is user productivity. Mod-

ern XRF equipment can take a mea-

surement in a few seconds with little

sample preparation and produce real-

time results that allow users to make

immediate decisions. XRF analysis is

also nondestructive. These are major

advantages compared to lab testing,

which often requires removing a seg-

ment of the sample and sending it to an

offsite lab for results. Another advan-

tage is ease of use. Modern XRF ana-

lyzers are smaller, faster, and smarter

instruments than previous generations.

This allows users without extensive

materials analysis training to measure

the elemental composition of a metal

pipe or component onsite.

What are you seeing with regard to

standards and legal requirements?

In the United States, we are see-

ing increased pressure from regulatory

groups like the EPA (Environmental

Protection Agency) and OSHA (Occu-

pational Safety and Health Adminis-

tration) demanding that asset holders

know the composition of materials they

have in place. Because portable ana-

lyzers are easier to use than earlier ver-

sions, employees at industrial sites are

beginning to conduct materials analysis

themselves. By enabling onsite workers

to conduct measurements without hir-

ing a third-party contractor or sending

samples to a lab, industrial sites can

prove to regulators that they have a

program in place to monitor and man-

age corrosion. As the oil refining and

petrochemical industries continue to

require more inspection and data col-

lection, we expect that use of portable

XRF metal analyzers will become even

more common.

~AM&P

For more information:

Brian Wilson is

business development manager, energy

markets,portableanalyticalinstruments,

Thermo Fisher Scientific, 2 Radcliff Rd.,

Tewksbury, MA 01876, 713.380.1287,

brian.k.wilson@thermofisher.com, ther-

mofisher.com/portableid.

Elemental content of steel piping inspec-

tion with the Niton XL5 XRF analyzer.

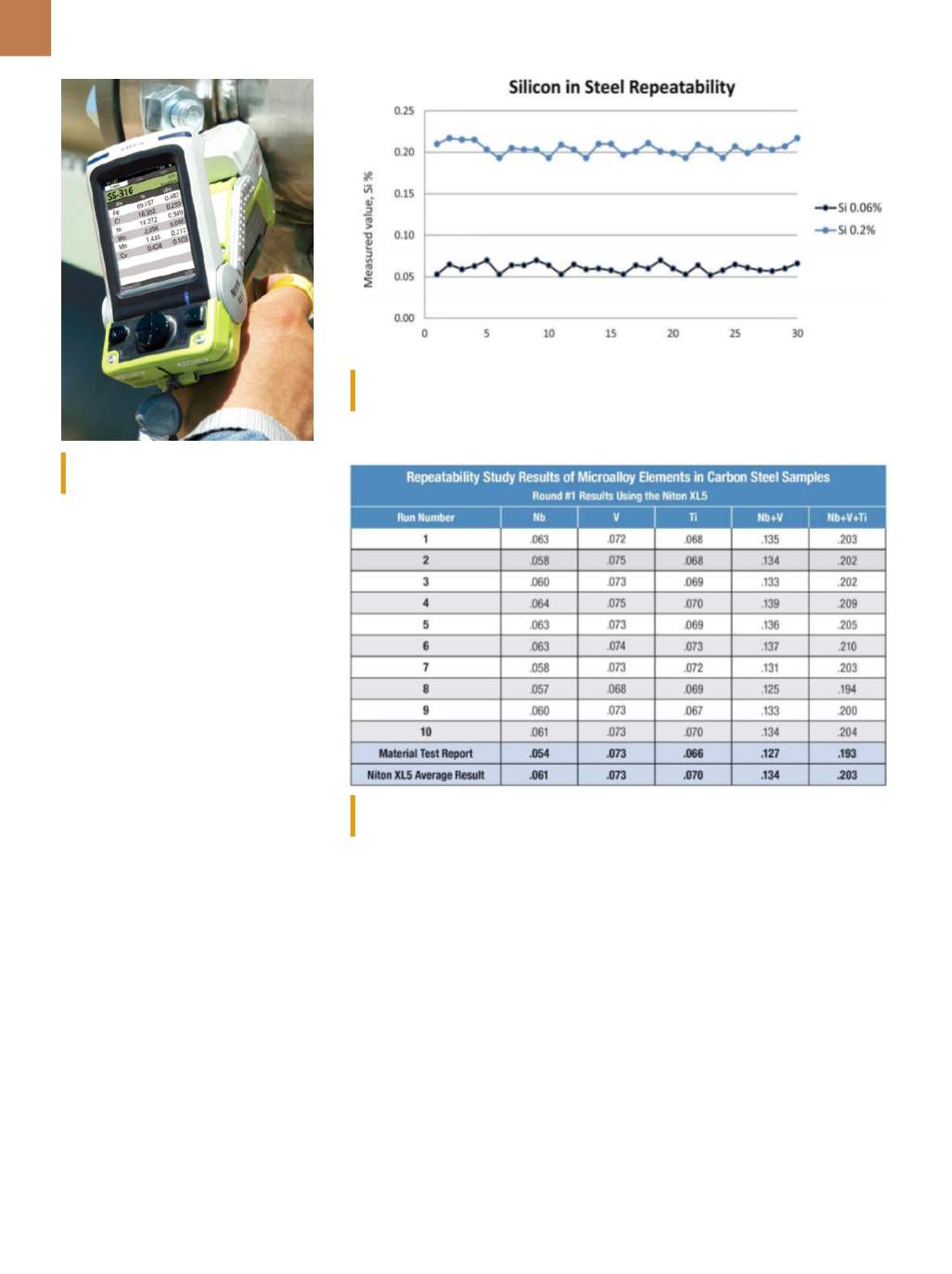

Low- and high-standard silicon in carbon steel measurement results using the

Niton XL5 XRF analyzer.

Microalloy element measurements of carbon steel samples using the Niton XL5 XRF analyzer

agree with laboratory test results.

Repeat measurements