A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

S E P T E M B E R

2 0 1 6

1 9

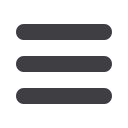

Fig. 3 —

(a) Electron back scatter diffraction map and (b) neutron radiograph before compres-

sion of equiaxed sample; (c) neutron radiograph of equiaxed sample after compression.

neutron diffraction strain mapping and

ESBD. Bragg edge radiography provides

grain orientation average over the thick-

ness of a sample, with differences in neu-

tron transmission due to the Bragg edge

scattering at wavelengths specific to

each crystal lattice plane. This technique

effectively measures crystal plane orien-

tation, assesses single crystal quality,

and quantifies Bragg edge shifts, which

are indicative of average strain through

the thickness of the material

at a neu-

tron pulsed source such as the SNS.

While interest in additive manufac-

turing is increasing, the role of process-

ing variables onmicrostructure is still not

sufficiently understood to enable pre-

dictive finite element modeling design.

Experimental measurements were per-

formed at the SNS Vulcan diffractometer,

which revealed localized reorientation

and refinement of grains due to compres-

sion. These preliminary results highlight

the potential of TOF neutron radiography

to contribute to the understanding of

AM materials characteristics. However, a

pixel-by-pixel study would provide more

detailed information. Further devel-

opments are aimed at enabling a pix-

el-by-pixel study, with potential spatial

resolution on the order of tens ofmicrons

and modeling of the Bragg edges to fur-

ther understand microstructure and its

evolution.

~AM&P

ACKNOWLEDGMENT

The team thanks M. Frost and

H. Skorpenske for setting up the detec-

tor at the SNS beamlines. Resources at

the High Flux Isotope Reactor and Spall-

ation Neutron Source, U.S. DOE Office

of Science User Facilities operated by

ORNL, were used in this research. This

research is also sponsored by the Lab-

oratory Directed Research and Devel-

opment Program of ORNL, managed by

UT-Battelle LLC, for DOE.

Formore information:

Hassina Bilheux

is neutron imaging lead instrument

scientist for the HFIR CG-1D and SNS

VENUS beamlines, Oak Ridge National

Laboratory, 1 Bethel Valley Rd., Oak

Ridge, TN 37831,

bilheuxn@ornl.gov,

865.384.9630, neutrons.ornl.gov.

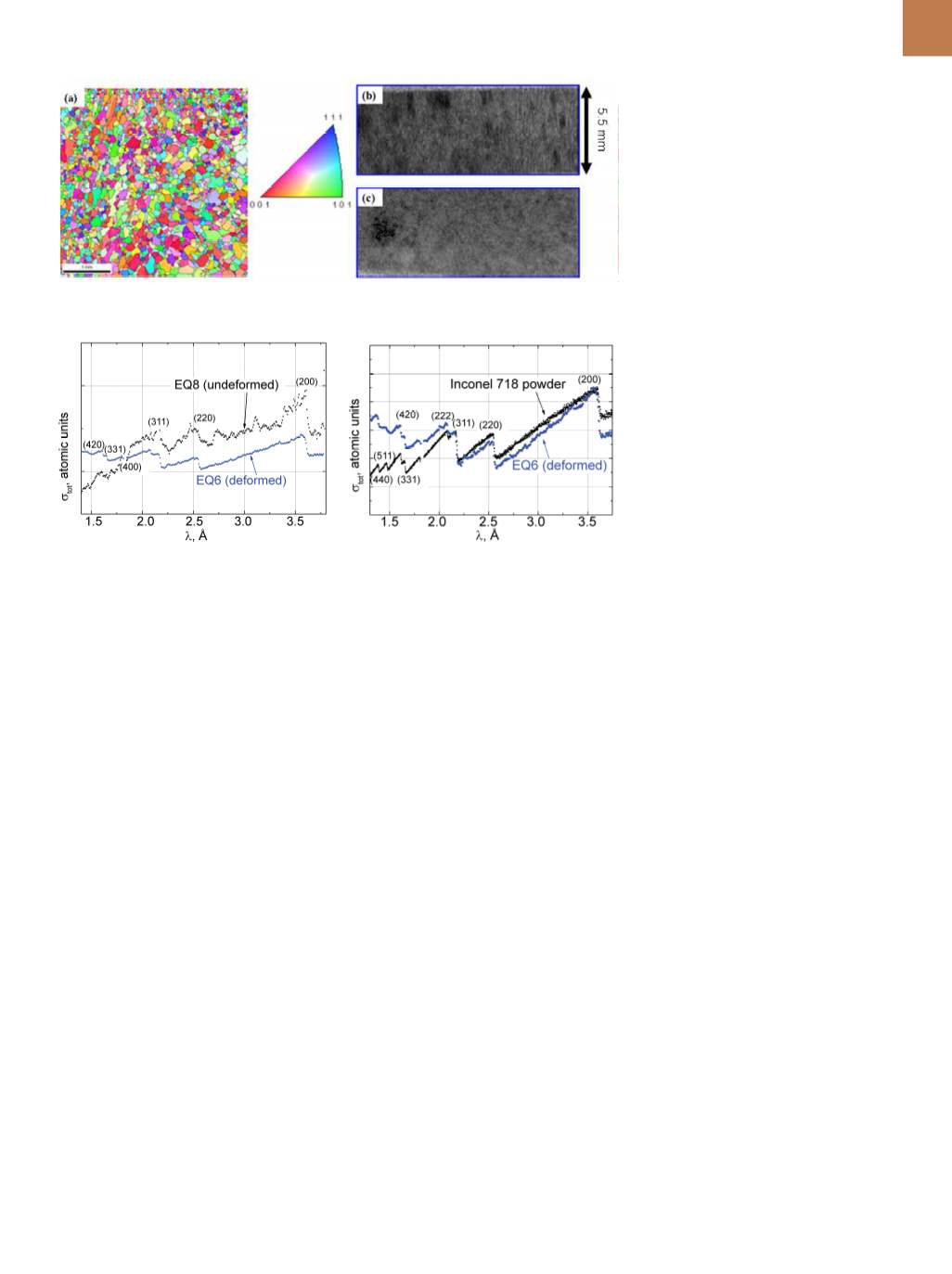

Fig. 4 —

Bragg edge mapping of as-fab-

ricated (undeformed) and compressed

(deformed) EQ8 and EQ6 equiaxed sam-

ples, respectively. Bragg edges of unde-

formed sample show presence of preferred

grain orientation (bumps between Bragg

edges), whereas Bragg edges of deformed

sample are similar to Inconel 718 powder,

indicating a local change in grain orien-

tation due to compression. Technique

provides pixel-by-pixel mapping of prefer-

ential grain reorientation.

Fig. 5 —

Bragg edge mapping comparison of

Inconel 718 powder and equiaxed deformed

sample EQ6.

(EBSD) grain orientation map for one of

the equiaxed samples.

After solidification and removal

from the stainless steel base plate,

samples were compressed 13% and

compared with their uncompressed

counterpart using Bragg edge radi-

ography (Fig. 3). Before compression,

grains with the same orientation are

visible in the radiograph (Fig. 3b), but

they realign preferentially due to com-

pression (Fig. 3c). These results are also

reflected in Bragg edge image analy-

sis (Fig. 4). Before compression, Bragg

edges are not as pronounced as in the

powder sample despite the fact that the

samples were printed with no preferred

grain orientation. A trend similar to that

in the powder sample (Fig. 2) might be

expected. The presence of “bumps” in

the Bragg edges of the uncompressed

sample EQ8 is likely due to the presence

of grains with a preferred orientation in

the sample (Fig. 3b).

After compression, sample EQ6 has

greater similarity to the Inconel powder

sample (Fig. 2), indicating the absence

of preferred crystallite orientation—as

if sample grains reoriented during com-

pression. A direct comparison between

Inconel powder and the deformed EQ6

sample is shown in Fig. 5. Bragg edges

are similar for both, while the (200) edge

for powder is higher, illustrating that the

(200) orientation is more predominant

in the deformed sample. Also, the (511)

Bragg edge in the deformed sample is

poorly defined, which is likely due to the

preferred grain orientation in the sam-

ple rather than instrument wavelength

resolution, because all measurements

were performed at the SNS Vulcan dif-

fractometer under the same beam optic

configuration.

CONCLUSIONS

ORNL has recently implemented

neutron radiography based on detect-

ing Bragg edge features to complement