iTSSe

TSS

A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J U L Y / A U G U S T

2 0 1 6

4 1

11

iTSSe

TSS

JTST

HIGHLIGHTS

The

Journal of Thermal Spray Technol-

ogy (JTST),

the official journal of the ASM

Thermal Spray Society, publishes con-

tributions on all aspects—fundamental

and practical—of thermal spray science,

including processes, feedstock manufac-

ture, testing, and characterization. As the

primary vehicle for thermal spray infor-

mation transfer, its mission is to syner-

gize the rapidly advancing thermal spray industry and related

industries by presenting research and development efforts

leading to advancements in implementable engineering appli-

cations of the technology. Articles from the June and August

issues, as selected by

JTST

Editor-in-Chief Armelle Vardelle, are

highlighted here. In addition to the print publication,

JTST

is

available online through springerlink.com. For more informa-

tion, please visit asminternational.org/tss.

NANOSTRUCTUREDANDCONVENTIONAL CR

2

O

3

,

TIO

2

, AND TIO

2

-CR

2

O

3

THERMAL-SPRAYED

COATINGS FOR METAL-SEATED BALL VALVE

APPLICATIONS IN HYDROMETALLURGY

Luc Vernhes, Craig Bekins, Nicolas Lourdel, Dominique

Poirier, Rogerio S. Lima, Duanjie Li, and Jolanta E.

Klemberg-Sapieha

Velan, an international industrial valve designer and

manufacturer, in collaboration with the National Research

Council of Canada, Boucherville, and Polytechnique Montréal

conducted a detailed characterization project to assess the

mechanical and tribological resistances of promising ceramic

coatings for hydrometallurgy applications, including a novel

n

-TiO

2

-Cr

2

O

3

blend. Hardness and shear strength were deter-

mined using microhardness indentation testers and univer-

sal tensile test equipment. Wear resistance of the coatings

under sliding wear, abrasion, and galling conditions were

measured by standard pin-on-disk tests, abrasion tests,

and custom-designed galling tests. The main result is that the

synergy between Cr

2

O

3

and

n

-TiO

2

produces abrasion perfor-

mance exceeding that of the materials alone. An optimized

balance between the hard and brittle Cr

2

O

3

phases and the

soft and ductile

n

-TiO

2

phases results in higher abrasion, slid-

ing, and galling resistance. The novel

n

-TiO

2

-Cr

2

O

3

blend is a

promising evolution of the current TiO

2

-Cr

2

O

3

blend.

A REVIEW OF THERMAL SPRAY METALLIZATION

OF POLYMER-BASED STRUCTURES

R. Gonzalez, H. Ashrafizadeh, A. Lopera, P. Mertiny,

and A. McDonald

A literature review on the thermal spray deposition of

metals onto polymer-based structures is presented. Deposit-

ing metals onto polymer-based structures enhances the ther-

mal and electrical properties of the resulting metal-polymer

material system. Thermal spray metallization processes and

the technologies for polymer-based materials are outlined.

Polymer surface preparation methods and the deposition of

metal bond-coats are also explored. Thermal spray process

parameters that affect the properties of metal deposits on

polymers are described, followed by studies on temperature

distribution within polymer substrates during thermal spray.

The objective of this review is devoted to testing and potential

applications of thermal-spray metal coatings deposited onto

polymer-based substrates. This review aims to summarize the

state-of-the-art contributions to research on the thermal spray

metallization of polymer-based materials, which has gained

recent attention for potential and novel applications.

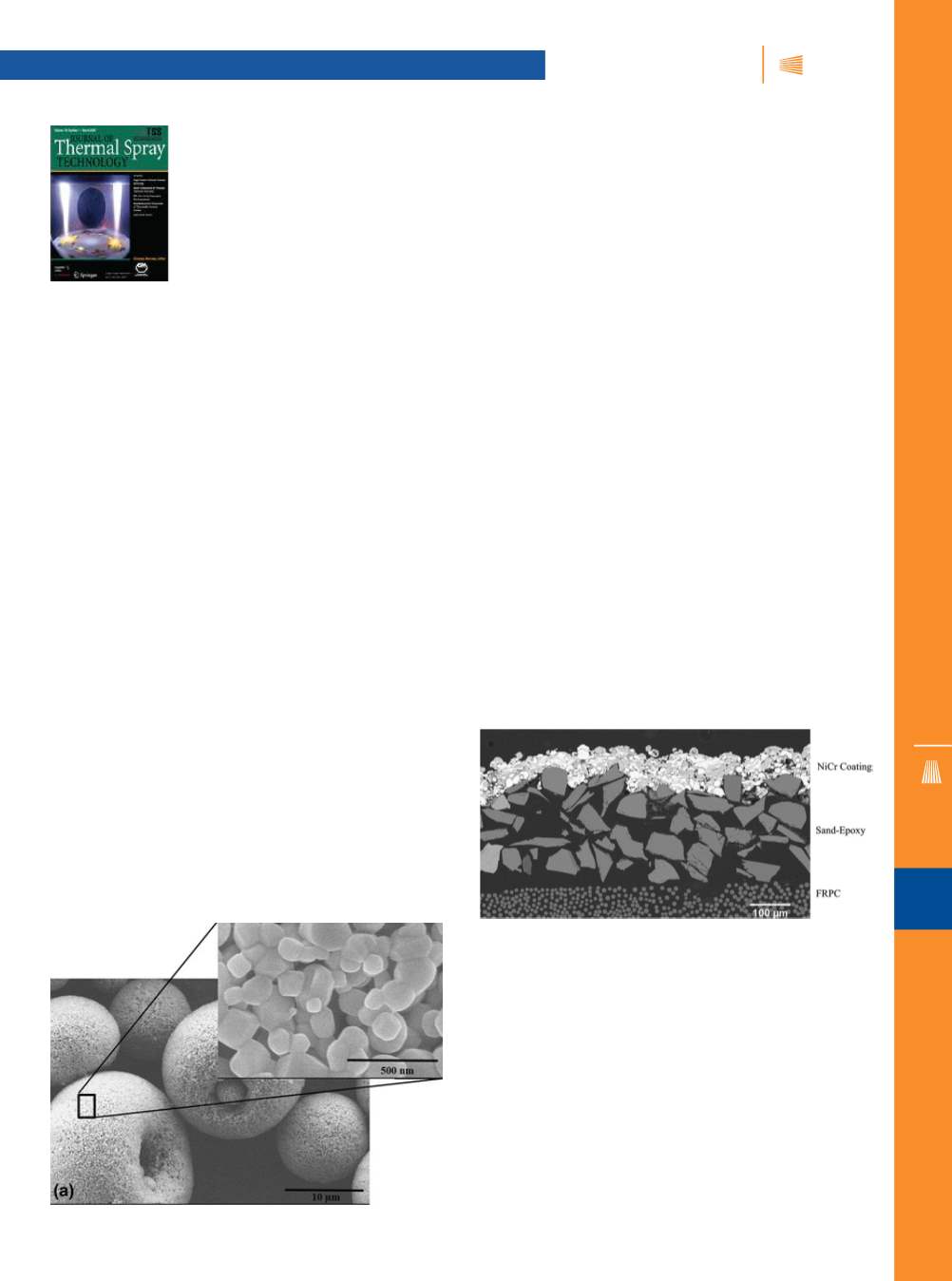

Fig. 1. —

n

-TiO

2

powder characteristics: SEMmicrographs.

Fig. 2. —

Backscattered scanning electron microscope image of the

cross section of a flame-sprayed Ni-20Cr coating deposited onto a

fiber-reinforced polymer composite substrate.

FABRICATION OF HIGH-TEMPERATURE

HEAT EXCHANGERS BY PLASMA SPRAYING

EXTERIOR SKINS ON NICKEL FOAMS

P. Hafeez, S. Yugeswaran, S. Chandra, J. Mostaghimi, and

T. W. Coyle

Thermal-sprayed heat exchangers were tested at high

temperatures (750°C), and their performance compared to

foam heat exchangers made by brazing Inconel sheets to

their surface. Nickel foil was brazed to the exterior surface of

10-mm-thick layers of 10 and 40 PPI nickel foam. A plasma