iTSSe

TSS

A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J U L Y / A U G U S T

2 0 1 6

3 7

7

iTSSe

TSS

FEATURE

coating thickness images. However, dark field mode is pref-

erable when a more quantitative assessment of coating

pores is desired.

iTSSe

For more information:

Dheepa Srinivasan is a principal engi-

neer at GE Power, GE India Technology Center, Bangalore,

dheepa.srinivasan@ge.com,

www.ge.com.

This article series is adapted from

Chapter 5, Cold Spray—

Advanced Characterization,

in High Pressure Cold Spray—

Principles and Applications, edited by Charles M. Kay and

J. Karthikeyan (ASM, 2016).

grinding and polishing to yield a mirror finish. Because most

of the samples are made of metallic or composite materials,

mechanical abrasive cutting or electrodischarge machine

wire cutting is typically used. However, in some cases, these

have been found to result in delamination of the coating

from the substrate, and therefore, waterjet cutting is rec-

ommended in order not to impart stresses during cutting.

Typically, samples are viewed in bright field mode to obtain

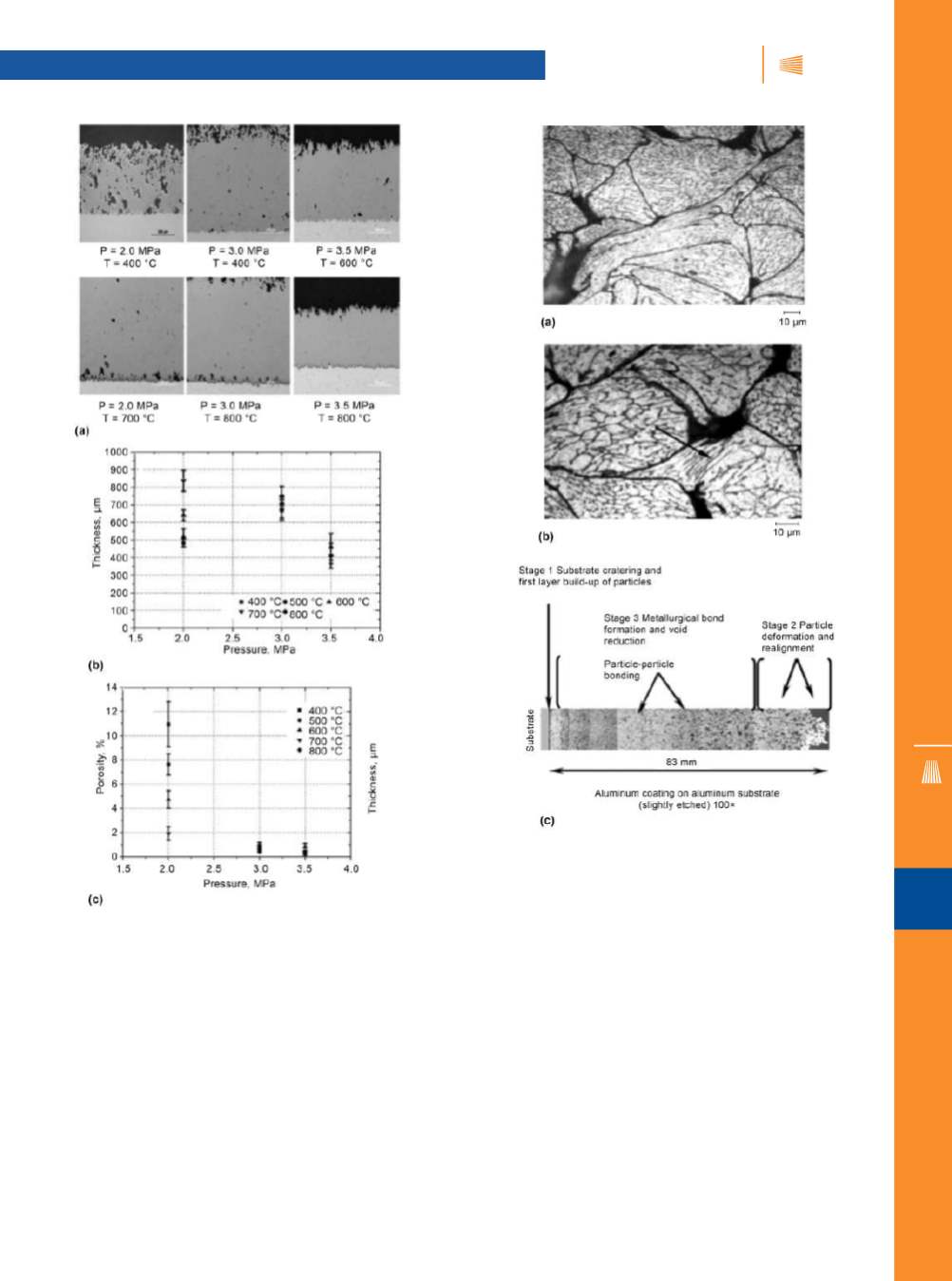

Fig. 3 —

Optical micrographs with etched aluminum coatings as a

function of gas temperature at 204°C (400°F) (a) and 315°C (600°F)

(b) reveal extent of particle deformation. Micrographs determine the

nature of the coating bond (c).

Fig. 2 —

Optical micrographs depict variation in porosity with

processing parameters for a Ti-64 coating on a SS304 substrate (a).

Variation of porosity with thickness and gas pressure as measured

from the optical micrograph (b, c).