iTSSe

TSS

A D V A N C E D M A T E R I A L S & P R O C E S S E S | J U L Y / A U G U S T 2 0 1 6

3 6

iTSSe

TSS

6

FEATURE ARTICLE

O

ptical or light microscopy (OM) uses the visible or

near-visible portion of the electromagnetic spectrum

and is one of the oldest characterization techniques.

With any cold spray coating, it is the first characterization pro-

cess used to evaluate and optimize process variables.

First, an estimate of the as-sprayed coating thickness

and coating porosity is evaluated, and an assessment of the

coating-substrate interface integrity is performed. The easi-

est way to assess coating formation as a function of various

coating parameters, such as spray angle, standoff distance,

raster speed, deposition efficiency, and powder feed rate,

is the optical microscope. Nearly all reports on cold spray

coatings begin with this characterization, which is funda-

mental to assess coating quality.

OM is often used to optimize process parameters for

obtaining dense, pore-free coatings. Trials on cold spray coat-

ings have been performed on several puremetals, such as alu-

minum, copper, titanium, tantalum, nickel, and magnesium,

as well as alloys based on aluminum (2052, 6061), magnesium

(AZ31B, ZE41A), nickel (IN718, IN625, IN738), and titanium (Ti-

64, CP-Ti), with optical micrographs of the as-processed coat-

ing. Inmost cases, coatings become denser when heat treated.

However, in certain cases, they become more porous.

A quantitative estimation of porosity, determined by

using image analysis attached to an optical microscope, is

usually the best way to characterize coating density. The

effects of process gas (helium vs. nitrogen vs. air) as well

as various process conditions, such as standoff distance,

speed, and deposition efficiency, are discerned by using OM.

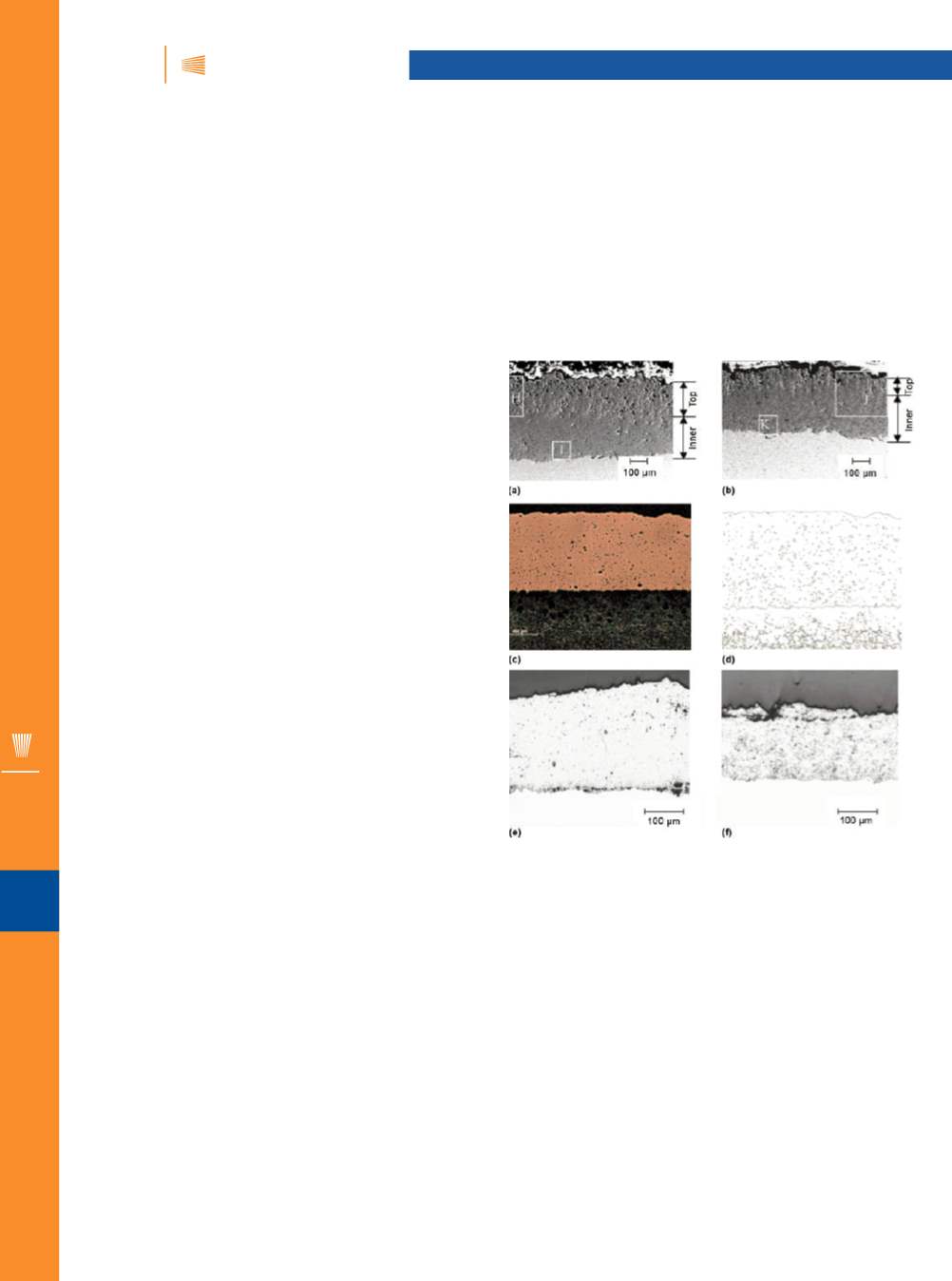

Figure 1 (a) and (b) show representative optical micro-

graphs comparing a

∼

0.3 mm (0.01 in.)-thick titanium cold-

spray coating, which was sprayed using nitrogen and helium

gas in the as-sprayed condition. A clear distinction can be

seen between the porous top region and the dense inner

region between the two coatings, revealing an important

aspect about the tamping effect of the two gases in the den-

sification of the coating.

Figure 1 (c) and (d) illustrate an image analysis of coat-

ing porosity measurement of a pure copper coating. The

optical micrographs in Fig. 1 (e) and (f) reveal coating inter-

face and surface, respectively, of a WC-Co coating. OM was

COLD SPRAY: ADVANCED CHARACTERIZATION

METHODS—OPTICAL MICROSCOPY

This new article series explores the indispensable role of characterization

in the development of cold spray coatings and illustrates some of the

common processes used during coatings development.

Dheepa Srinivasan, GE Power, GE India Technology Center, Bangalore

Fig. 1 —

Optical micrographs show comparison of overall coating

thickness and top layer thickness between a nitrogen-spray and

helium-spray copper coating, respectively (a, b); image analysis

evaluated porosity in a pure copper coating (c, d); and interface and

top surface in a WC-Co cermet coating sprayed using nitrogen gas

(e, f).

used to map process variables to obtain dense coatings for

an aluminum coating, by etching an aluminum coating and

mapping the microstructure evolution as a function of tem-

perature as shown in Fig. 2 (a) and (b).

Observation of the nature of particle deformation and

input from optical micrographs enables numerical simula-

tion, as shown in Fig. 3 (a) to (c). Sample preparation for OM

is usually straightforward involving metallography, namely

cutting the coating either transversely or along the direc-

tion of spray, mounting the cross-section using a resin, and