iTSSe

TSS

A D V A N C E D M A T E R I A L S & P R O C E S S E S | J U L Y / A U G U S T 2 0 1 6

4 0

iTSSe

TSS

10

CASE STUDY

REASON TO CONSIDER SURFACING

Using thermal spray to coat the interiors of pipes and

tubes used in heavy duty applications enhances mechani-

cal properties and extends component lifetimes. However,

thermal spray processing of internal diameters (IDs) creates

a range of processing challenges related to both workpiece

diameter and length. The physical size of equipment, hoses,

and spray distance boundaries—along with temperature and

contamination issues—are considerations for both equipment

andmaterial manufacturers.

H.C. Starck GmbHandUniqueCoat Technologies recently

conducted a range of trials to optimize coating properties pro-

duced with new hardware designed to coat IDs down to less

than 5 in., an application area that has traditionally been a

challenge for the production of high quality coatings.

VALUE OF COATING

The flame characteristics (thermal and kinetic) had to

be matched to a spray material that would provide coating

quality comparable to that achieved by larger standard coat-

ing equipment. This is especially important for heavy duty

industries such as oil and gas, where ID protection in drilling

and pumping applications has long been an area requiring

improvement. In order tomatch the spray device to the correct

powder consumable, a few simple principles must be taken

into account:

1. Can the hardware be sized to allow for consistent

energy transfer (both thermal and kinetic) to the pow-

der, in order to reach the desired particle temperature

and velocity to produce a high quality coating—dense,

hard, and well bonded, at a reasonable efficiency?

2. Can the powder be produced to a very tightly con-

trolled specification on a consistent basis so that opti-

mum coating properties are reliable and reproducible

for ID applications?

OPTION

Specially sized materials of very specific morphology

were used to run coating trials to find the optimum match

between the small ID torch’s energy (UniqueCoat’s I7 torch)

OPTIMIZING COATING MATERIALS FOR

HEAVY DUTY APPLICATIONS

TABLE 1

—

TRIAL RESULTS

Powder

designation

Hardness –

HV300 Porosity Powder

sizing (µm)

Morphology

Amperit 558.185

1140

<1% -30 + 5

Agglomerated sintered

Amperit 554.071

1380

<1% -25 + 5

Sintered crushed

Amperit 554.090

1540

<1% -20 + 5

Sintered crushed

Amperit 554.067

1502

<1% -15 + 5

Sintered crushed

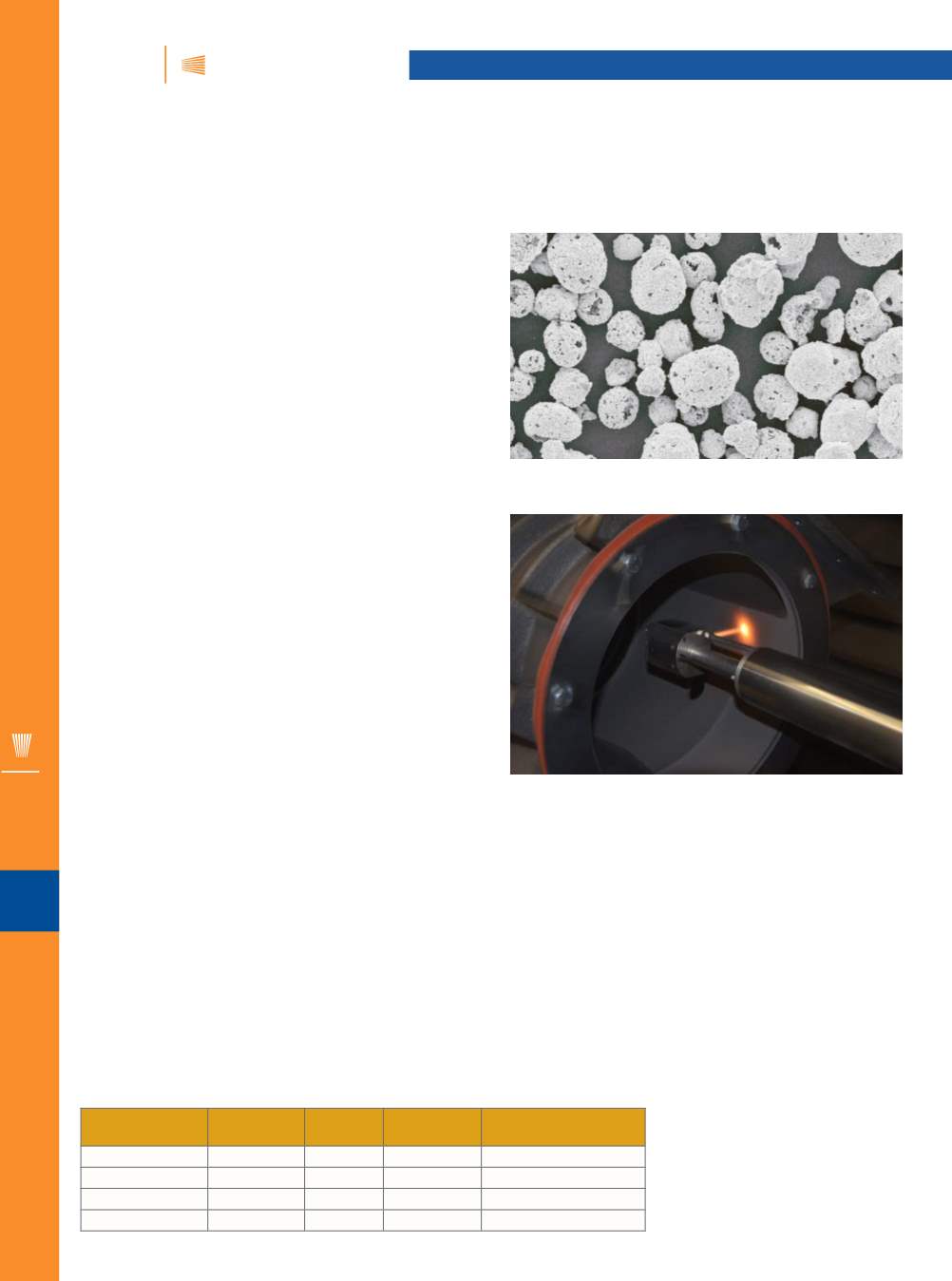

Fig. 1 —

Amperit 558—spray dried/agglomerated and sintered.

Courtesy of H.C. Starck GmbH.

and the size and thermal conductivity of the spray material

(Fig. 1). Coating chemistry was WC/Co/Cr (86/10/4)—a coating

commonly used in the oil and gas industry due to its mix of

wear and corrosion resistance. Trial results appear in Table 1.

BENEFITS

The I7 torch coating the interior of a rotary valve is shown

in Fig. 2, an application that will be run as part of a large scale

evaluation of this emerging technology. Further trials will

focus on optimizing the performance of specialized coatings

for erosion and slurry resistance.

iTSSe

For more information:

Michael Bre-

itsameter is senior global sales man-

ager, H.C. Starck North American

Trading LLC, 45 Industrial Place, New-

ton, MA 02461, 617.893.7367, michael.

breitsameter@hcstarck.com, www.

hcstarck.com.

Fig. 2 —

UniqueCoat’s I7 torch coating the internals of a rotary valve.