iTSSe

TSS

A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J U L Y / A U G U S T

2 0 1 6

4 3

iTSSe

TSS

13

JTST

HIGHLIGHTS

Finally, this article briefly describes performance profiles

required to fulfill biological functions of osseoconductive bio-

ceramic coatings designed to improve osseointegration of hip

endoprostheses and dental root implants.

PHYSICOCHEMICAL CHARACTERISTICS OF

DUST PARTICLES IN HVOF SPRAYING AND

OCCUPATIONAL HAZARDS: CASE STUDY

IN A CHINESE COMPANY

Haihong Huang, Haijun Li, and Xinyu Li

Dust particles generated during thermal spray pose a

serious health risk to operators. Particles generated in the

high velocity oxy-fuel (HVOF) spray of WC-Co coatings were

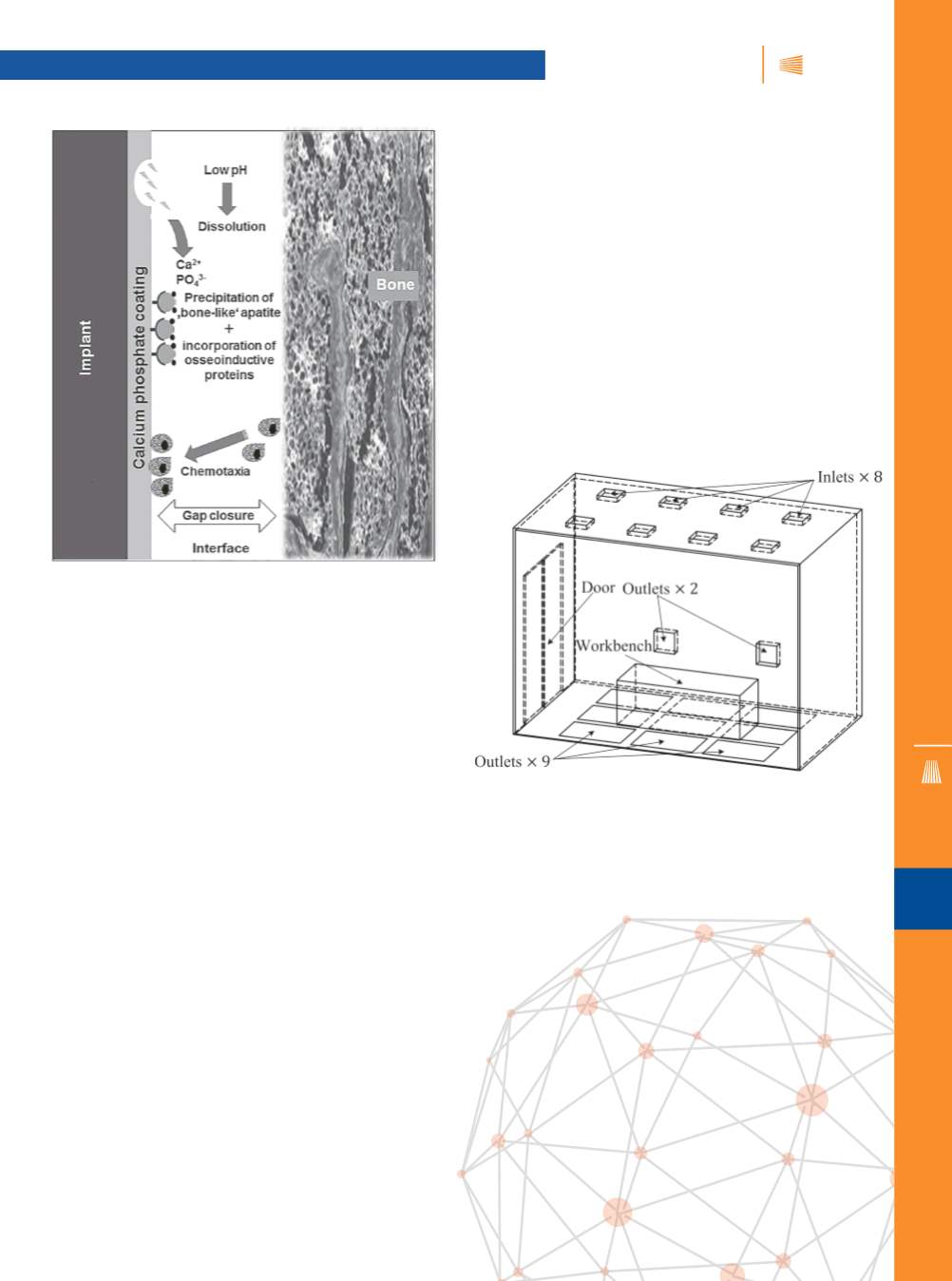

Fig. 4. —

Schematic of cell-implant interaction mediated by a thin

calciumphosphate coating layer. A local decrease of pH results in

partial dissolution of the coatings, triggering the release of chemo-

taxia frombone. Addition of Ca

2+

and PO

4

3-

ions increases supersat-

uration of the extracellular fluid (ECF) with respect to hydroxylap-

atite, precipitating bone-like apatite and promoting subsequent

incorporation of osseoinductive proteins such as osteocalcin and

osteonectin as well as annexins and integrins.

characterized in terms of mass concentrations, particle size

distribution, micro morphologies, and composition. Results

show that the highest instantaneous exposure concentration

of dust particles is 140 mg/m

3

and the time weighted average

concentration is 34.2 mg/m

3

, which are approximately eight

and four times higher than the occupational exposure limits in

China, respectively. Large dust particles bigger than 10

μ

m in

size present a unique polygonal morphology or irregular block

of crushed powder, and smaller dust particles mainly exist in

the form of irregular or flocculent agglomerates. Some heavy

metals, such as chromium, cobalt, and nickel, are also present

inworkshop air with concentrations that exceed exposure lim-

its. Potential occupational hazards are further analyzed based

on dust particle characteristics. Exposure to the nanoparticles

is assessed using a control banding tool.

Fig. 5. —

Workshop schematic.