3 2

A D V A N C E D M A T E R I A L S & P R O C E S S E S | J U N E 2 0 1 6

6

FEATURE

H

eat treatment is a critical part of the manufacturing

process for a wide range of products, such as those

used in consumer goods, power generation, automo-

biles, aerospace, and many others. The quality and safety of

heat treated products is of utmost importance to both the

companies that produce them and consumers. Maintain-

ing global quality standards in heat treating not only helps

ensure the highest quality of components used in aero-

space applications, but also helps heat treaters continually

improve and refine their processes to provide the best prod-

uct quality for all applications. Aerospace Material Specifica-

tion (AMS) standards and Nadcap (National Aerospace and

Defense Contractors Accreditation Program) play key roles

in ensuring thatmanufacturers performing heat treating and

other special processes adhere to consistent, high-quality

standards for producing aerospace products.

A series of articles, beginning with this one, will discuss

questions and challenges that can arise about the Nadcap

accreditation process, specifications involved, and other

process considerations. Recommended best practices and

steps from those who have undergone Nadcap accreditation

are presented to help simplify the process, including:

•

Tips on preparing for internal and official Nadcap

audits, including networking with other suppliers

and establishing an approved quality system.

•

Where to locate key documents and specifications

that help you prepare for the audit process.

•

Review of common nonconformances (NCR) to better

understand certain specifications and requirements.

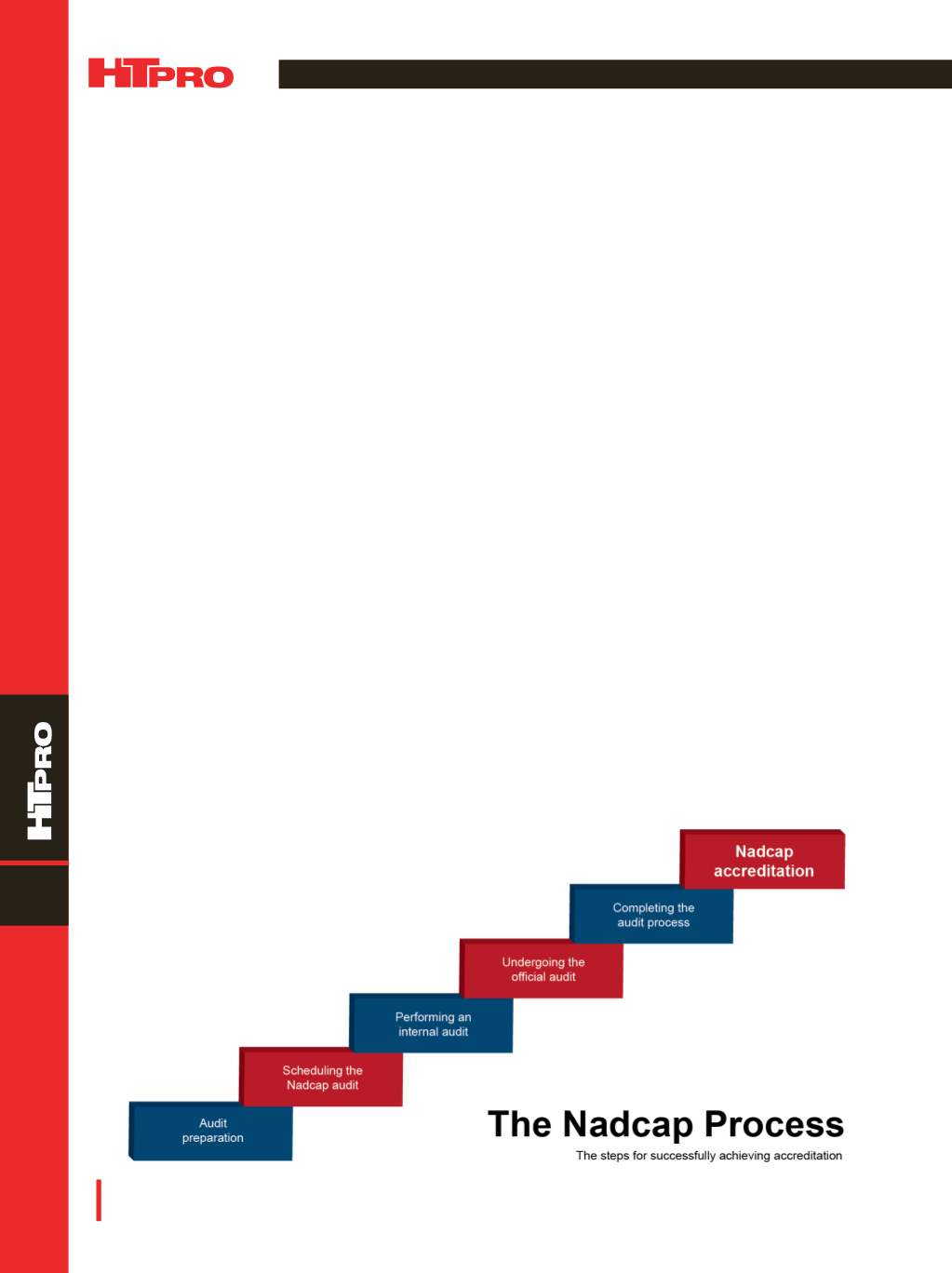

While every heat treater’s Nadcap audit is

unique (depending on processes, types of equip-

ment, and specific customer spec-

ifications), a Nadcap accreditation

process typically involves:

OBTAINING NADCAP ACCREDITATION:

HELPFULGUIDELINES FOR PASSING YOUR AUDIT

Learn how to simplify the process of obtaining Nadcap accreditation for your heat treating

facility by paying heed to some of the challenges others have experienced.

Nathan Durham,

Ipsen USA, Cherry Valley, Ill.

•

Requesting and scheduling an audit

•

Performing an internal audit

•

Implementing corrective actions for findings from the

internal audit

•

Undergoing an official audit

•

Reviewing and responding to NCR findings

•

Applying corrective actions to resolve remaining

issues

•

Receiving Nadcap accreditation

•

Whether participating in a Nadcap audit for the first

time, or going through the reaccreditation process,

many companies continually refine their audit pro-

cess based on NCRs found during the internal and

official audit.

PREPARING FOR AN AUDIT

The Nadcap audit process is lengthy and complex, but

those who adequately prepare are able to make it through

this endeavor without difficulty. Often, the biggest challenge

is knowing where to start. Considering the following prepa-

ratory actions will help:

Locating key documents and specifications.

To prepare

for a quality audit, the first step is to knowwhich documents

Overview of the typical Nadcap accreditation process, which often depends on specific primary contractor specifications, processes,

equipment, andmore. Courtesy of Ipsen.

PART I