3 1

A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J U N E

2 0 1 6

5

CHTE UPDATE

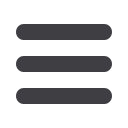

Fig. 1 —

Magnetic parameter (MP) changes with surface hardness.

PROJECT STEPS

The team analyzed several surface hardness and case

depth measurement techniques, including eddy current,

meandering winding magnetometer (MWM), and alternat-

ing current potential drop (ACPD), before concluding that

Barkhausen noise testing and ACPD best support the proj-

ect objectives. (Note: More work needs to be done on ACPD

before insights can be shared.) Several widely used alloy

steels including AISI 8620/9310/1018/5120 were carburized

and fully characterized with destructive testing. Samples

were also tempered. The concentration profile, hardness

profile, and retained austenite percentage were experimen-

tally determined. The team is now determining correlations

among nondestructive test measurements and hardness

and microstructure for standards, and then verifying the

effectiveness of nondestructive test techniques in industry

applications.

THE PROCESS

CHTE measured the properties of steel with Barkhau-

sen testing and found a good correlation between surface

hardness and the Barkhausen noise result. Magnetic param-

eter (MP) was measured with the Rollscan 350 unit from

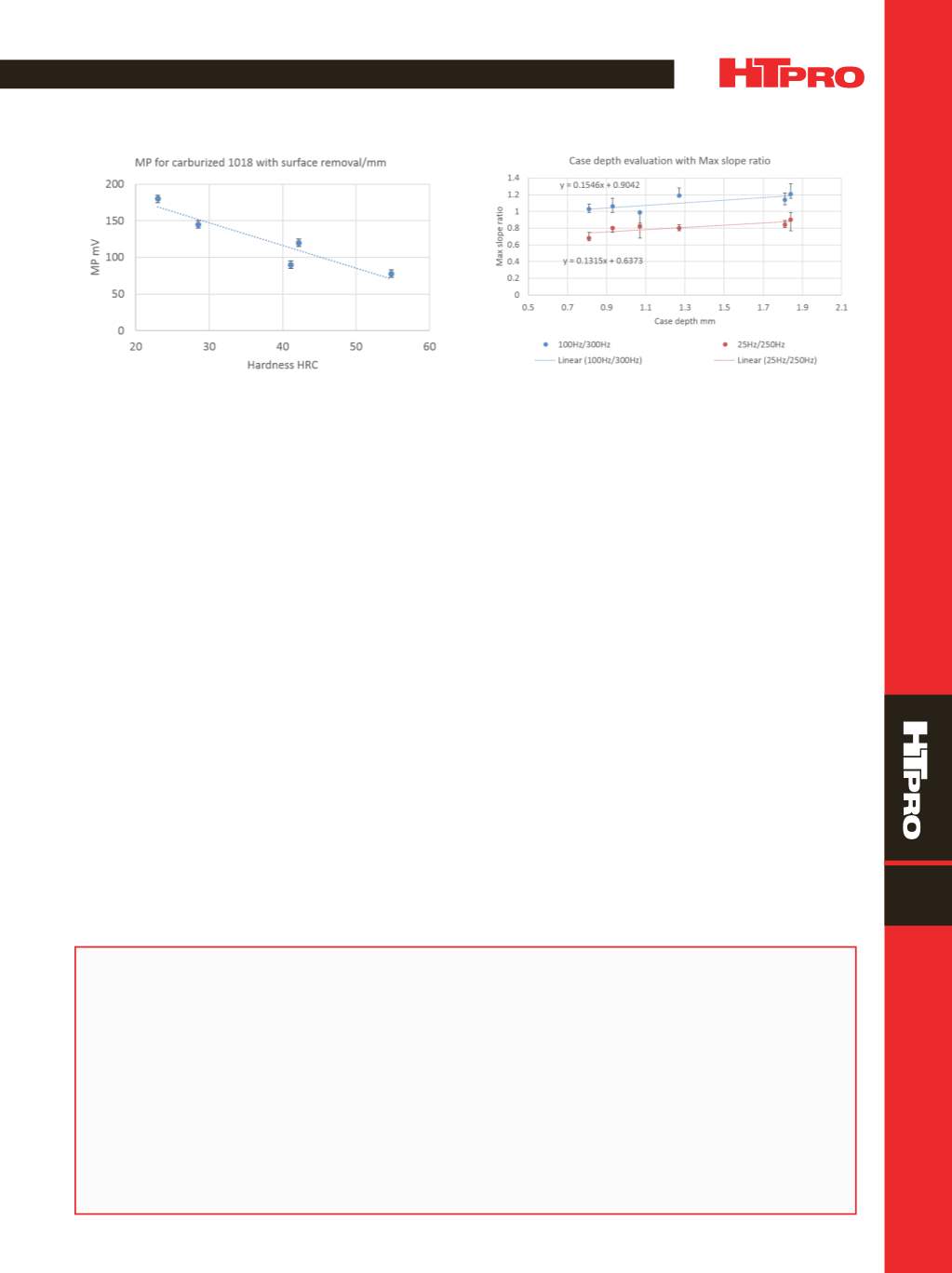

Fig. 2 —

Maximum slope ratio changes with case depth.

American Stress Technologies (AST). Carburized AISI 1018

samples were prepared using the surface removal method.

Samples display different surface hardness due to the car-

bon concentration difference. MP is sensitive to hardness as

shown in Fig. 1.

Due to the industry’s need for case depth evaluation,

additional testing with Barkhausen noise is being con-

ducted by CHTE, which includes the effects of grain size,

tempering condition, and microstructure. Working with

AST, researchers used the magnet voltage sweep method

for case depth testing. The Rollscan 350 unit can mea-

sure the MP by scanning the exiting voltage from 0 to 18

Vpp. Data is collected with software and the maximum

slope of the curve is recorded. With measurement from

two different frequencies, properties of the sample from

different depths can be evaluated. The slope ratio of the

two frequencies is then correlated with case depth as pre-

sented in Fig 2. Completion of this CHTE research project is

expected in December.

For more information:

Visit

wpi.edu/+chte, call

508.831.5592, or email Rick Sisson

(sisson@wpi.edu) or

Diran Apelian

(dapelian@wpi.edu).

The CHTE collaborative is an alliance between the indus-

trial sector and university researchers to address short-term

and long-term needs of the heat-treating industry. Member-

ship in CHTE is unique because members have a voice in se-

lecting quality research projects that help them solve today’s

business challenges.

Research projects are member driven. Each research

project has a focus group comprising members who provide

an industrial perspective. Members submit and vote on pro-

posed ideas, and three to four projects are funded yearly.

Companies also have the option of funding a sole-sponsored

project. In addition, members own royalty-free intellectual

property rights to precompetitive research and are trained on

all research technology and software updates.

CHTE is located in Worcester, Mass., on WPI’s New En-

gland campus. The university was founded 150 years ago this

year. For more information about CHTE, its research projects,

and member services, visit

wpi.edu/+chte, call 508.831.5592,

or email Rick Sisson at

sisson@wpi.edu, or Diran Apelian at

dapelian@wpi.edu.

ABOUT CHTE