3 7

A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J U N E

2 0 1 6

FEATURE

11

Fig. 3 —

ORNL industrial prototype magnetic processing equipment

includes 8-in. diam. vertical warm-bore superconducting magnet

system and Ajax Tocco Magnethermic 200-kW dual-frequency

induction heating systemwith 75-gpmpolymer-water quench.

Fig. 4 —

Improvement in single-tooth bending fatigue life of ITMP

gears over baseline properties.

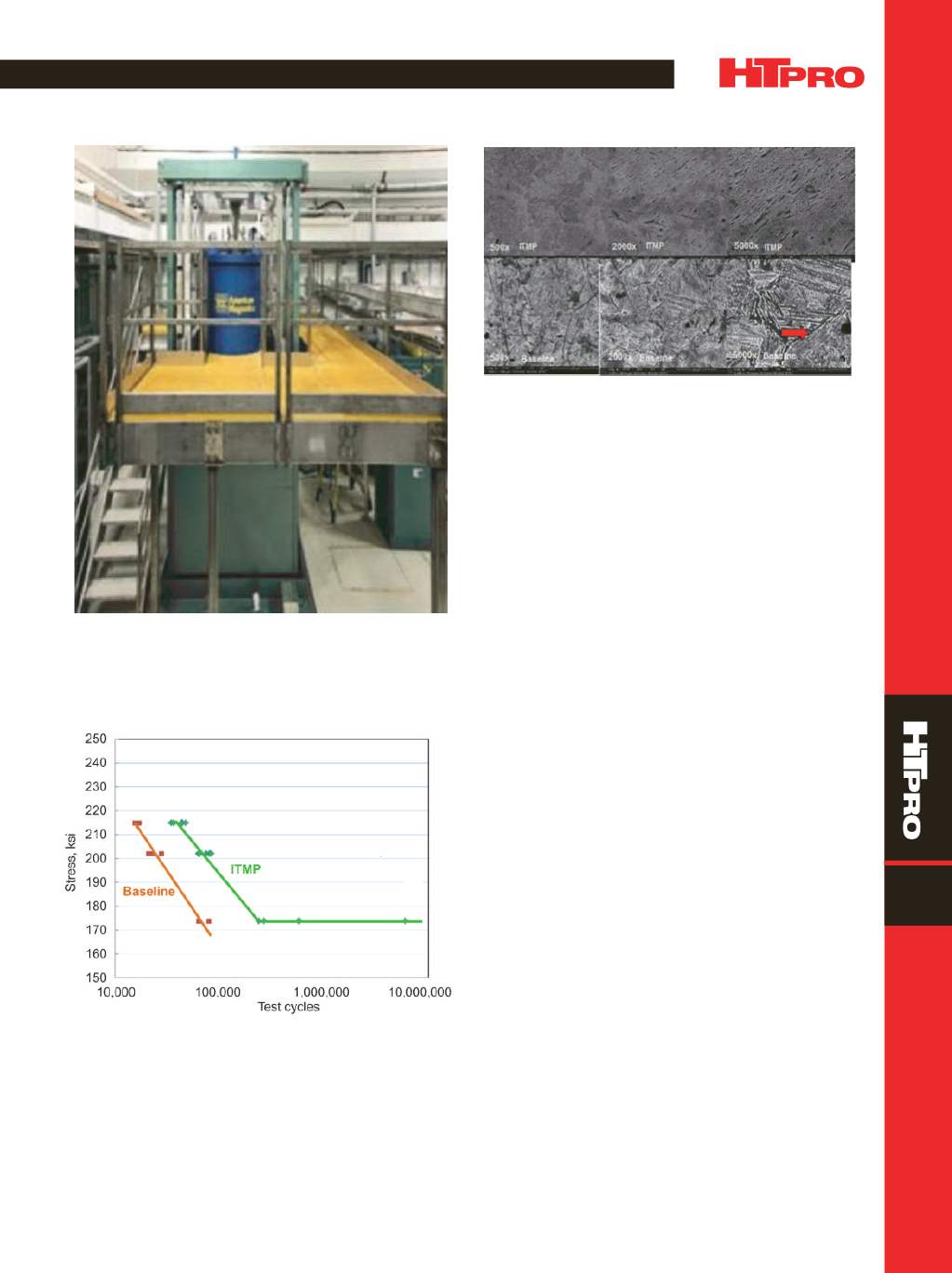

Fig. 5 —

Microstructure of ITMP (top) and baseline gear (bottom).

ITMP gear has a refinedmartensitic structure and fine carbides.

Grain boundary in baseline gear indicated by red arrow.

Acknowledgment

This report is based on research supported by the

U.S. DOE under Award No. DE-FG36-08GO18131 with Eaton

Corp. as the primary lead, using the Thermomagnetic

Processing Facilities at ORNL, supported by the Office of

Energy Efficiency and Renewable Energy.

This manuscript has been authored by UT-Battelle

LLC under Contract No. DE-AC05-00OR22725 with the

DOE. The U.S. Government retains and the publisher, by

accepting the article for publication, acknowledges that

the Government retains a non-exclusive, paid-up, irre-

vocable, worldwide license to publish or reproduce the

published form of this manuscript, or allow others to do

so, for Government purposes. The DOE will provide public

access to these results of federally sponsored research in

accordance with the DOE Public Access Plan (

energy.gov/ downloads/doe-public-access-plan).

References

1. G. Ludtka, et al., Exploring Ultrahigh Magnetic Field

Processing of Materials for Developing Customized

Microstructures and Enhanced Performance, ORNL Tech.

memo, ORNL/TM-2005/79, Mar., 2005,

www1.eere.energy. gov/manufacturing/industries_technologies/imf/pdfs/ 1792magneticprocessingfinal.pdf.2. G. Ludtka, et al., Magnetic Field Processing – A

Heat Free Heat Treating Method, ORNL Tech. memo,

ORNL/TM-2012/78, Aug. 2012,

www.osti.gov/servlets/ purl/1049805/.

3. M. Lusk, et al., Effect of Austenitization Hold Time and

Temperature on Matrix Carbon Content and Martensite

Kinetics in 52100, unpublished research, Colorado School

of Mines.

For more information:

Aquil Ahmad is retired from Eaton

Corp., Cleveland. He can be reached at

ahmadaquil@sbc- global.net.

•

From a sustainability perspective, an 85% reduction

in energy use is estimated when using ITMP versus

conventional processing for the gears.

•

As presented in Fig. 1, low cost steels can rival exotic

costly alloys in properties and performance when

using ITMP.