A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J U N E

2 0 1 6

1 9

IN-SITU EBSD TECHNIQUE

CHARACTERIZES

MICROSTRUCTURE EVOLUTION

OF MAGNESIUM ALLOY

An in-situ annealing technique combined with EBSD characterizes the

microstructural evolution of an Mg alloy as a function of temperature.

Ajith Chakkedath, Carl Boehlert,* and David Hernandez, Michigan State University, East Lansing

Jan Bohlen, Sangbong Yi, and Dietmar Letzig, Magnesium Innovation Centre MagIC, Germany

I

n-situ scanning electron micros-

copy (SEM) enables microstructure

evolution to be studied under vari-

ous loading conditions. Modern SEMs

incorporate heating assemblies so they

can be tilted to the optimum angle for

electron backscatter diffraction (EBSD)

analysis. This, combined with the fast

indexing capabilities of fully automated

modern EBSD systems, enables micro-

structure evolution to be captured

during in-situ heating experiments.

In-situ EBSD heating experiments

are typically performed to enable

understanding of phase transforma-

tions and/or recrystallization behavior

as a function of temperature and/or

time

[1]

. Such experiments have been

used to study the microstructural

evolution and recrystallization in alu-

minum alloys, copper, titanium, and

steel

[1]

. Similar studies help explain the

microstructural evolution in wrought

magnesium (Mg) alloys, in which the

crystallographic texture has significant

influence on elongation-to-failure

[2]

and

anisotropy in mechanical properties

[3]

.

Control of the crystallographic

texture in wrought Mg alloys is of

commercial interest. Conventional

Mg alloys tend to form strong texture

during wrought processing and retain

that texture after annealing

[4,5]

, which

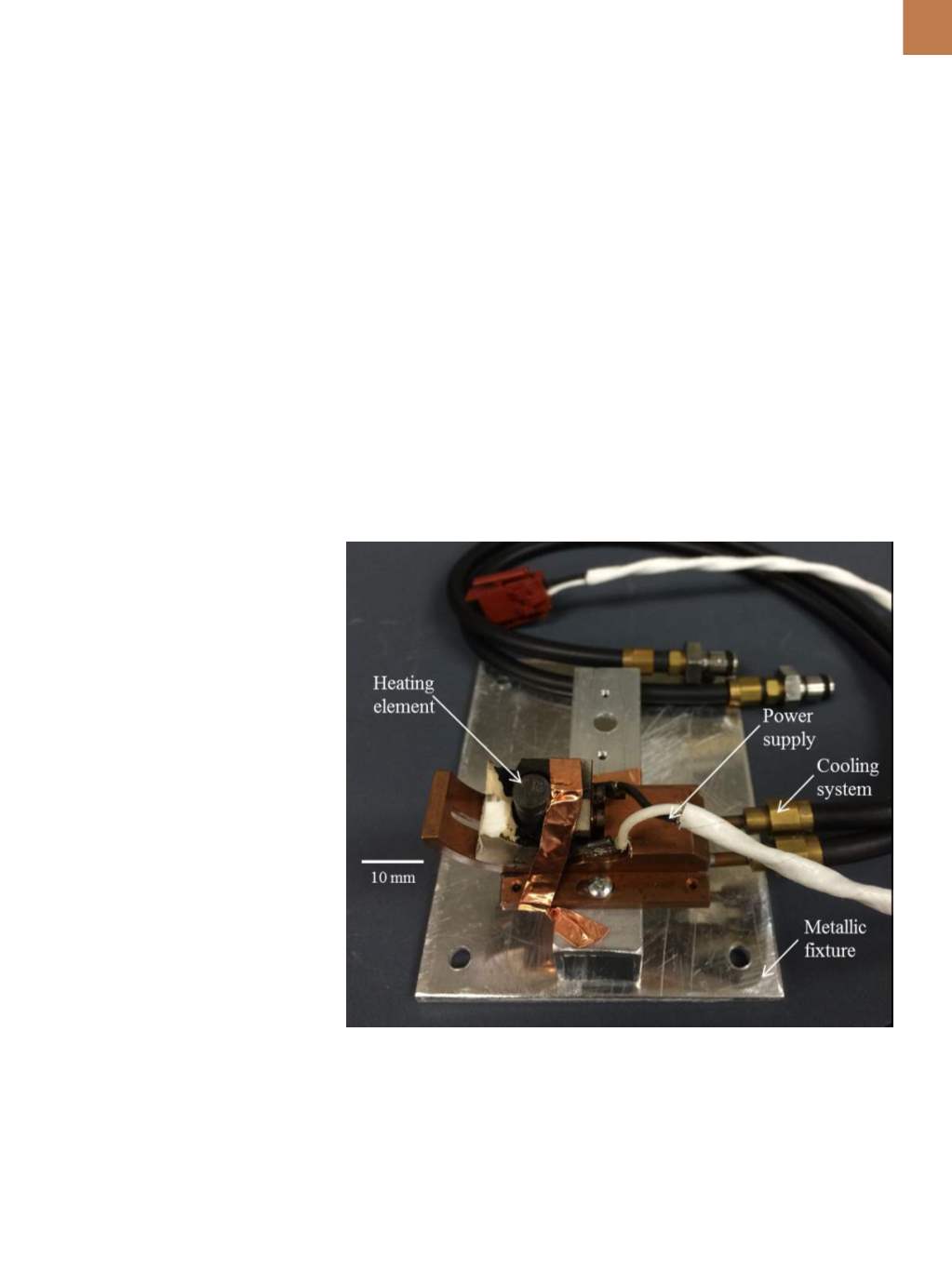

Fig. 1 —

Heating stage used for in-situ heating experiments. The sample (not shown) was placed

directly on top of the heating element during experiments.

makes further processing difficult. Rare

earth (RE) containing Mg alloys form

weaker textures during wrought pro-

cessing (and subsequent annealing)

[6,7]

.

However, the underlying mechanisms

responsible for this texture develop-

ment in Mg alloys during annealing are

not well understood

[8,9]

. Therefore, an

in-situ annealing technique combined

with EBSD was developed in order to

characterize the microstructural evolu-

tion as a function of temperature in a

RE-containing Mg alloy, Mg-2Zn-0.2Ce

(wt%) (ZE20).

*Member of ASM International