A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J U N E

2 0 1 6

1 3

PROCESS TECHNOLOGY

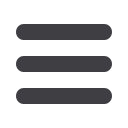

Martin Thuo with a vial of liquid-metal particles. Courtesy of Christopher Gannon.

SOLDERING METHOD KEEPS

ITS COOL

Researchers at Iowa State Uni-

versity, Ames, demonstrated a method

of producing microscale, liquid-metal

particles for use in heat-free soldering

and material healing at room tempera-

ture. Scientists have long used a meth-

od called undercooling—in which liq-

uid metal is prevented from returning

to a solid state even below its melting

point—to study metal structure and

processing. However, producing large

and stable quantities of undercooled

metals has proved challenging. The

team hypothesized that covering tiny

droplets of liquid metal with a thin,

uniform coating could result in stable

particles of undercooled liquid metal.

Using a high-speed rotary tool, they

sheered liquid metal into droplets with-

in an acidic liquid, then exposed the

particles to oxygen, forming an oxida-

tion layer that encapsulated the liquid

Shuting Lei is working on better ways to

machine ultrathin precision parts.

BRIEF

Constellium N.V.,

the Netherlands, opened the Constellium University Technol-

ogy Center (UTC) at

Brunel University,

UK, to design, develop, and prototype

aluminum alloys and automotive structural components. The new center will

feature industrial-size aluminum casting and extrusion equipment as well as

rapid prototyping, which is expected to reduce development time by at least

50% for the advanced alloys used in automotive lightweighting.

constellium. com, www.brunel.ac.uk.

metal. Researchers proved the concept

by creating liquid-metal particles 10 µm

in diameter containing Field’s metal (an

alloy of bismuth, indium, and tin) as

well as particles of the same size con-

taining an alloy of bismuth and tin.

Martin Thuo, assistant professor of

materials science and engineering, says

the project is a good example of “frugal

innovation,” a guiding principal for his

lab, which strives to solve problems

using the fewest resources. The team

demonstrated healing damaged surfac-

es and joining metals at room tempera-

ture without high-tech instrumenta-

tion, complex material preparation, or a

high temperature process.

iastate.edu.

MACHINING BRITTLE

MATERIALS WITH CRACK

CONTROL

Shuting Lei, professor of indus-

trial and manufacturing systems en-

gineering at Kansas State University,

Manhattan, received a $300,000 grant

from the National Science Foundation

to develop better methods of machin-

ing ultrathin precision parts. “Precision

parts made from brittle materials such

as glass and ceramics have broad appli-

cations in the health care, biomedical,

energy, and photonics areas,” says Lei.

“A major problem in machining these

materials is random crack propagation

into the work piece. This results in sub-

surface cracks and thus degrades the

strength of the machined parts.” His

award will support development of a

novel machining process that over-

comes this limitation using controlled

crack propagation. The new method

will enable high-efficiency machining of

brittle materials without compromising

part quality.

k-state.edu.