A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J U N E

2 0 1 6

1 1

To test the new configuration,

researchers used a cell containing

a lithiated oxide cathode, a silicon-

graphite anode, and various electro-

lytes, including ones containing fluo-

roethylene carbonate (FEC) or vinylene

carbonate (VC) additives. While silicon-

containing electrodes could double the

energy stored in lithium-ion cells—a

boon for extending electric vehicle driv-

ing range—these cells degrade more

quickly. The Argonne team used the

new configuration to test the impact

of the FEC and VC additives, and con-

firmed their beneficial effects, not only

at reducing capacity loss but in mitigat-

ing the impedance rise in cells without

them.

anl.gov.IMAGING A BETTER FUTURE

FOR UK STEEL

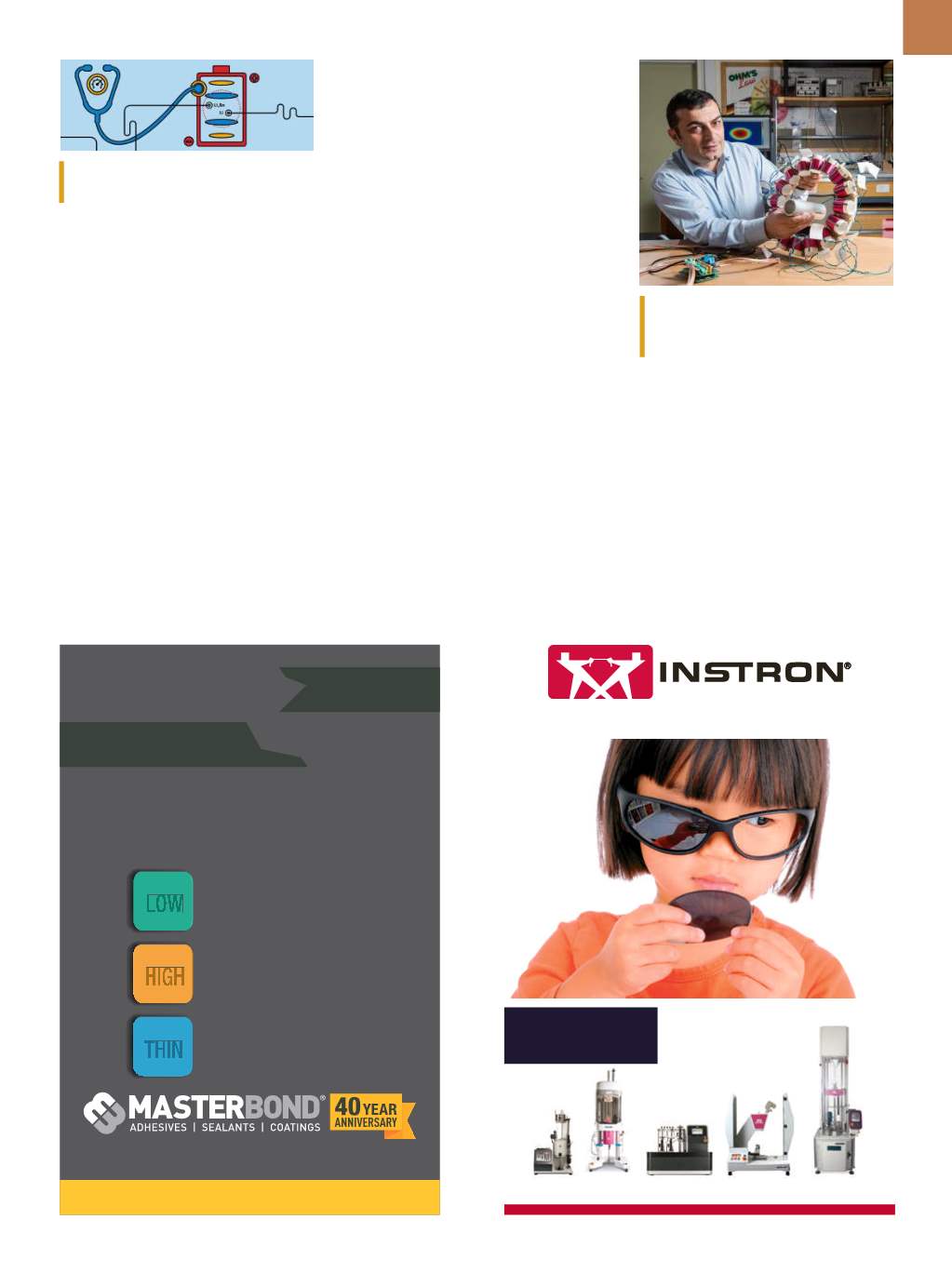

Manuch Soleimani, a researcher

from the University of Bath, UK,

received a grant to develop a real-time,

nondestructive, reliable measurement

method for detecting defects or failures

in molten steel during continuous cast-

ing. The process involves positioning a

contactless bracelet around the billet to

continually measure the electrical con-

ductivity of the different states of the

solidifying steel, providing an image of

the structural composition of the steel

as it cools. Soleimani, associate profes-

sor in the department of electronic and

electrical engineering, received a three-

year EU Horizon 2020 grant to develop

the method, which uses induction

tomography, an emerging, noninvasive

imaging technique already employed in

applications such as medical diagnos-

tics, geophysical exploration, and civil

engineering. He will collaborate with

colleagues at the Fundacion Tecnalia

Two reference electrodes within a battery

cell.

Manuch Soleimani is leading a three-year

project to develop new technology to

support the UK & EU steel industry.

Research and Innovation, Spain, as

well as Italian steel companies Ferriere

Nord and Ergolines Lab on the so-called

Shell-Thick project. Hopes are high

that the process could boost the com-

petitiveness and sustainability of the

UK and EU steel industries, which face

stiff competition from highly subsidized

steel production in China.

www.bath. ac.uk. LOW THIN HIGH The of thermal management HIGHS & LOWS One Part Epoxy Features Very Low Thermal Resistance Supreme 18TC Thermal resistance, 75°F 5-7 x 10 -6 K•m 2 /W Forms bond lines as thin as 10-15 microns Thermal conductivity, 75°F 3.17-3.61 W/(m•K) 154 Hobart St., Hackensack, NJ 07601 USA +1.201.343.8983 mainmasterbond.com www.masterbond.com Are you Ready to Face the Aftermath of your Material’s failure? Visit go.instron.com/polymertesting to find out why Melt Flow, Rheology, HDT Vicat, Impact are important parts of a polymer laboratory 825 University Avenue, Norwood, MA 02062 | 1.800.564.8378 | go.instron.com/polymertesting