A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

M A Y

2 0 1 5

2 3

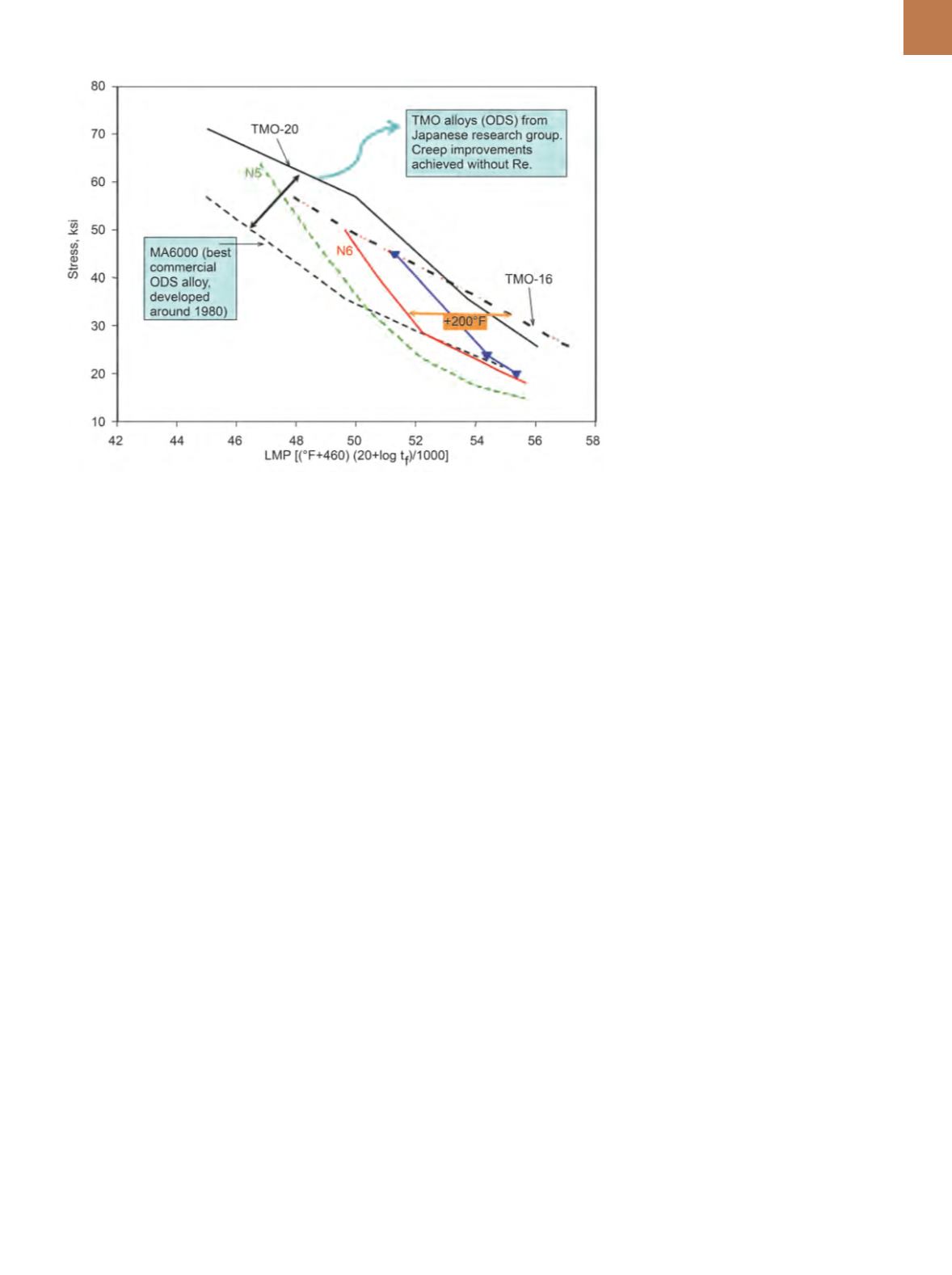

results is that the exceptional creep

properties were obtained without any

Re additions.

These properties underlie the cen-

tral reason for the current proposal to

revive ODS alloys as turbine blade ma-

terials. Exceptional creep properties

were already demonstrated in com-

positions that are inherently ductile,

oxidation and corrosion resistant, and

of acceptable density. Further, design

of ODS alloys is comparatively unex-

plored, so the opportunity for future

improvements is quite large. For ex-

ample, MA6000’s high Cr content (15%)

and low refractory metal content reflect

its targeted application of industrial gas

turbines and betrays its age—and is a

major reason for optimism in predicting

improved properties via alloying.

POTENTIAL BARRIERS

TO ODS ALLOYS

As mentioned previously, in the

1980s and 90s, ODS alloys suffered from

competing with single-crystal superal-

loys. Described here are past ODS short-

comings, which can serve as a list for

technology improvements required to

develop these alloys for future engines.

Competition from single crystals

in terms of creep strength

. Continued

improvements in single-crystal proper-

ties since the 1980s are reported in the

literature, in contrast to very limited

improvements in ODS alloys, especial-

ly over the temperature range of inter-

est from 750

o

to 1100

o

C. As described

previously, it is under-appreciated that

exceptional creep properties were gen-

erated in Re-free alloys by Glasgow

in 1976 and Kawasaki, et al., in 1990.

These studies may have been discount-

ed due to other issues with ODS alloys,

but they have more significance now

because development of single-crystals

appears to have reached a point of lim-

ited improvements.

Competition from single crystals in

terms of cost and near-net shape pro-

cessing with internal cooling passages

.

The high-cost processing route for ODS

alloys was exacerbated in components

with complex hollow geometries. How-

ever, the cost differential has shrunk,

because advanced single-crystal alloys

contain substantial amounts of ex-

pensive elements such as Re, Ru, and

Ta. Also, complex cooling geometries

can be achieved by fabricating blades

from stacked wafers with etched cool-

ing passages

[21]

. While the methods are

not inexpensive, they became more vi-

able as they matured over the past 20

years. Another potential route to lower

costs is improving the mechanical al-

loying process, including application

of modern process-modeling methods.

Several new processing methods are

applied to Fe-base alloys

[22]

and might

work with Ni alloys. Also, on a cost ba-

sis, ODS alloys compare more favorably

than CMCs.

Low ductility of ODS alloys

. ODS

alloys have low ductility, especially in

transverse directions

[23]

. They also suf-

fer from embrittlement due to prior

creep exposure

[24]

. However, experience

with low ductility materials has broad-

ened since the 1980s, and ductilities

of ODS alloys reported in earlier pub-

lications do not seem as intimidating

to engineers experienced with

γ

-TiAl

and CMCs, especially when combined

with fracture toughness values of about

40 MPa √ —m

[25]

. In addition, convention-

al superalloys also suffer from reduced

ductility after high temperature expo-

sure

[26]

, yet still perform well in service.

A reexamination of ductility is an essen-

tial part of a revitalized ODS develop-

ment program. However, incorporating

alternative tests to determine ductil-

ity, such as ballistic impact testing

[27]

,

would be more relevant to the intended

application.

Anisotropy in ODS alloys

. MA6000

has a predominantly [110] texture after

directional recrystallization, and TMO

alloys have textures ranging from [100]

to [111], depending on the alloy. This

raises a question of whether exception-

al creep properties in ODS alloys are a

result of their non-[001] orientations.

This appears to be unlikely, because

creepanisotropy at temperatures above

1000

o

C is generally not very significant.

The debit in thermal fatigue resistance

in non-[001] orientations

[28]

is also of

concern. This is a more serious issue

and must be addressed in future devel-

opment efforts. Two lines of thought

indicate a degree of optimism that the

issue can be resolved. First, it is known

that texture after recrystallization is a

function of alloy composition

[29]

, and

it is conceivable that a more desirable

texture can be achieved through alloy

and process development. Second, a

wafer-blade processing scheme allows

for reorienting wafers prior to bonding.

Fig. 3 —

Early ODS alloys show substantial improvements in creep capability over the best

single crystals, which is still true today, and without any refractory element additions

[18,19]

.