A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A Y 2 0 1 5

2 2

levels for cracking and environmental

ingress, poor response to foreign object

impact events, and moisture-induced

recession effects in high combustion

pressures

[6]

, requiring reliance on envi-

ronmental barrier coatings on compo-

nent surfaces

[7]

. Thus, it is still prema-

ture to assume ubiquitous applications

of CMCs throughout an engine.

Significant resources were invest-

ed over the past 20 years on high-tem-

perature silicides as potential replace-

ments for superalloys. MoSi

2

-

[8]

, MoSiB-

[9]

and NbSi-

[10]

base alloys emerged from

screening numerous research results as

the most promising candidates, as they

improved strength, toughness, and ox-

idation resistance. However, no alloys

were developed with the balance of

properties required for a turbine blade,

especially for a high-pressure turbine. In

addition, many improvements in tough-

ness were achieved through compos-

iting strategies, which can be equally

applied to CMCs that have much lower

density than any other silicide. Thus,

there appears to be very little room for

silicides between superalloys and CMCs.

The recent discovery of

γ

-

γ

’

mi-

crostructures in Co-base alloys has

sparked interest

[11]

. Advantages include

higher melting points and improved so-

lidification behavior compared with Ni-

base alloys, and high toughness com-

pared with ceramics. However, their

high densities (exceeding 9 g/cm

3

), low

γ

’

solvus, and unknown oxidation re-

sistance remain formidable barriers to

their use. While it is too early to rule

out Co-base alloys as candidates for

high-pressure turbines, the alloy strat-

egy is yet unproven.

In this article, the case is made

for what appears to be “low-hanging

fruit” to replace single crystals as high-

pressure turbine blades—oxide disper-

sion strengthened (ODS) Ni-base alloys.

ODS alloys combine proven technology,

substantial gains in capability over to-

day’s alloys, and a clear development

path to overcome identified risks.

HISTORICAL BACKGROUND

Mechanically alloyed ODS super-

alloys were developed in the 1970s,

primarily by Inco Alloys. Both Fe- and

Ni-base alloys were developed and

commercialized, and are used in aircraft

gas-turbine engines and industrial tur-

bines

[12]

. Components include turbine

blades and vanes, nozzles, and com-

bustor/augmenter assemblies. Howev-

er, ODS alloys fell out of favor and have

not been actively pursued in the U.S. for

more than 20 years.

Mechanical alloying is used to pro-

duce a uniform distribution of submi-

cron oxide particles in a highly alloyed

matrix

[13]

. Alloys are formed from pure

elemental or pre-alloyed powders plus

about 2 vol% very fine (25 nm) yttria

(Y

2

O

3

). The powder mixture is milled in

high-energy ball mills to fully homoge-

nize the elemental additions, followed

by consolidation and hot working. Typ-

ically, ODS alloys are then directional-

ly recrystallized to form an elongated

grain structure. After milling and con-

solidation, Y

2

O

3

is converted to yttrium

aluminum garnet (YAG). FeCrAl-base

alloys MA956 and PM2000, NiCrAl-

base solid solution alloys MA754 and

PM1000, and

γ

’-strengthened MA6000

were the most widely used alloys.

Oxidation and hot corrosion resis-

tance of commercial ODS alloys range

from good to excellent

[14]

. In addition,

ODS alloy compositions are so similar

to those of superalloy single crystals

that compatibility with existing alu-

minide and overlay coatings

[15]

, as well

as TBCs, is expected to be excellent.

Solid-solution alloys have excellent

creep strengths at very high tempera-

tures, usually at or above 1100

o

C. How-

ever, creep strengths at intermediate

temperatures (750-850

o

C) are much

lower than

γ

’-strengthened alloys. MA

6000 was developed to compete with

single crystals as a turbine airfoil alloy,

and is strengthened by both oxides and

γ

’. It has significantly improved interme-

diate temperature creep strength with-

out sacrificing very high temperature

strength. Benn and coworkers devel-

oped more advanced alloys, known as

Alloys 51 and 92, that improved the in-

termediate temperature creep strength

of MA6000

[16]

.

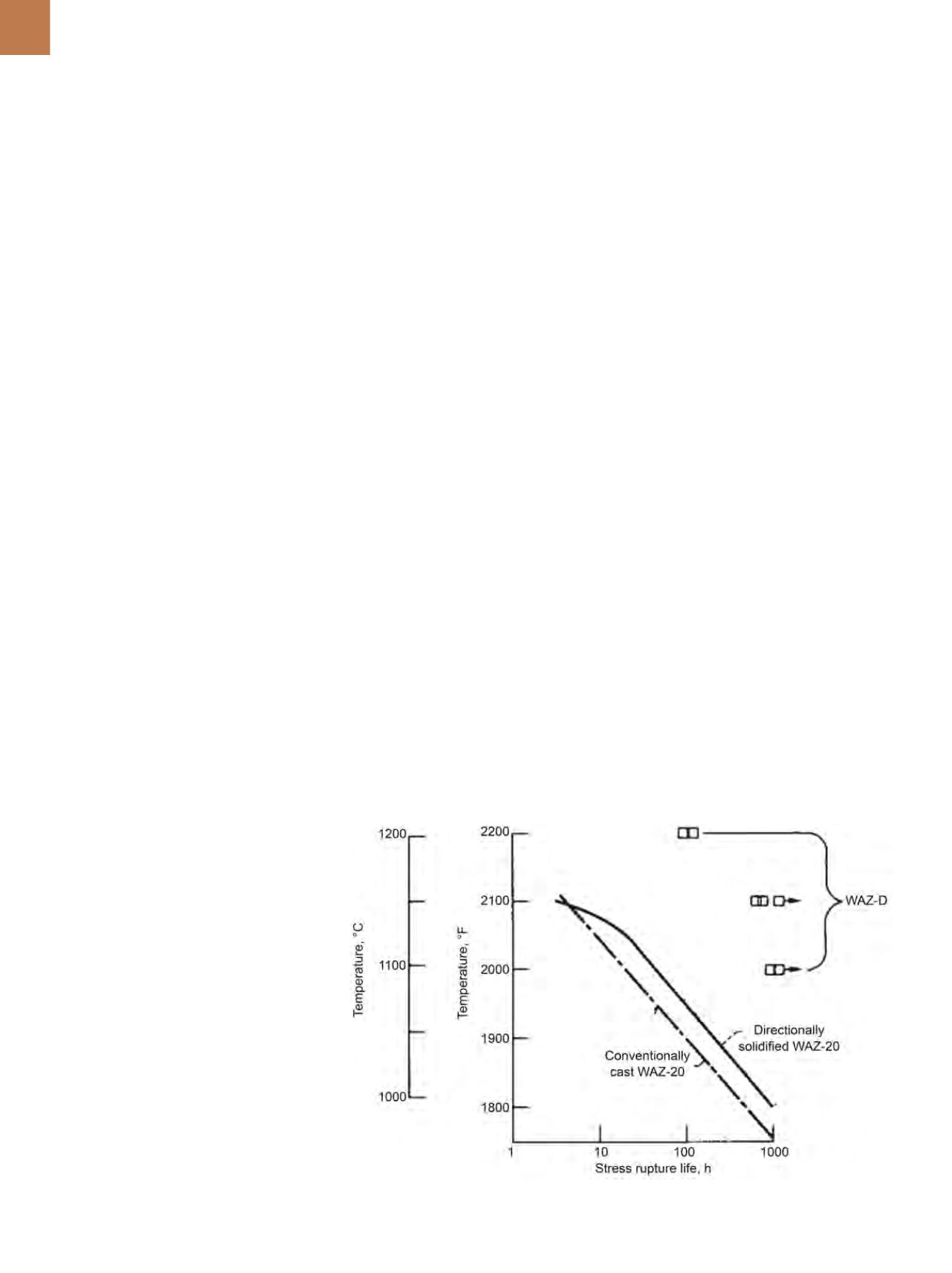

Most importantly, two other stud-

ies show substantial improvements

in high-temperature creep strength.

Glasgow

[17]

showed that combining ODS

with

γ

’ strengthening produced an alloy

with more than 150

o

C increase in tem-

perature capability compared with the

same alloy with

γ

’ strengthening only

(Fig. 2). Kawasaki, et al.

[18,19]

, reported

exceptional creep properties for two

alloys, TMO-20 and TMO-16. Figure 3

shows that TMO-16 has a 100

o

C ad-

vantage over Rene N6 at 200 MPa. Al-

loy densities of ~8.9 g/cm

3

, calculated

using JMatPro

[20]

, are roughly equiva-

lent to third generation single-crystal

alloys. An important feature of these

Fig. 2 —

Benefits from combining

γ

’ and oxide strengthening. ODS alloy WAZ-D shows a creep

strength improvement of 130

o

C over WAZ-20, with essentially the same composition

[17]

.