A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

M A Y

2 0 1 5

2 1

ADVANCED TURBINE

AIRFOIL DEVELOPMENT

STRATEGIES: HARVESTING

LOW-HANGING FRUIT

Oxide dispersion strengthened alloys still have potential to improve turbine

blade temperature capability beyond that of superalloy single crystals.

Mike Nathal, NASA Glenn Research Center (retired), Cleveland

A

high-pressure turbine rotor is sub-

jected to the most demanding

conditions in the turbine engine,

which places stringent requirements on

the materials used. Turbine blades re-

quire a balance of creep resistance, high

temperature capability, environmental

resistance, and damage tolerance. To-

day’s blade performance and durability

are achieved through a combination of

advanced alloys, sophisticated internal

cooling schemes, and thermal barrier

coatings (TBCs). Turbine blades have

been made of nickel-base superalloy sin-

gle crystals for 30 years. Improvements

in alloy strength were achieved over the

years by increasing refractory element

(RE) content and reducing chromium

content, and the various alloys are cat-

egorized into about four generations of

development.

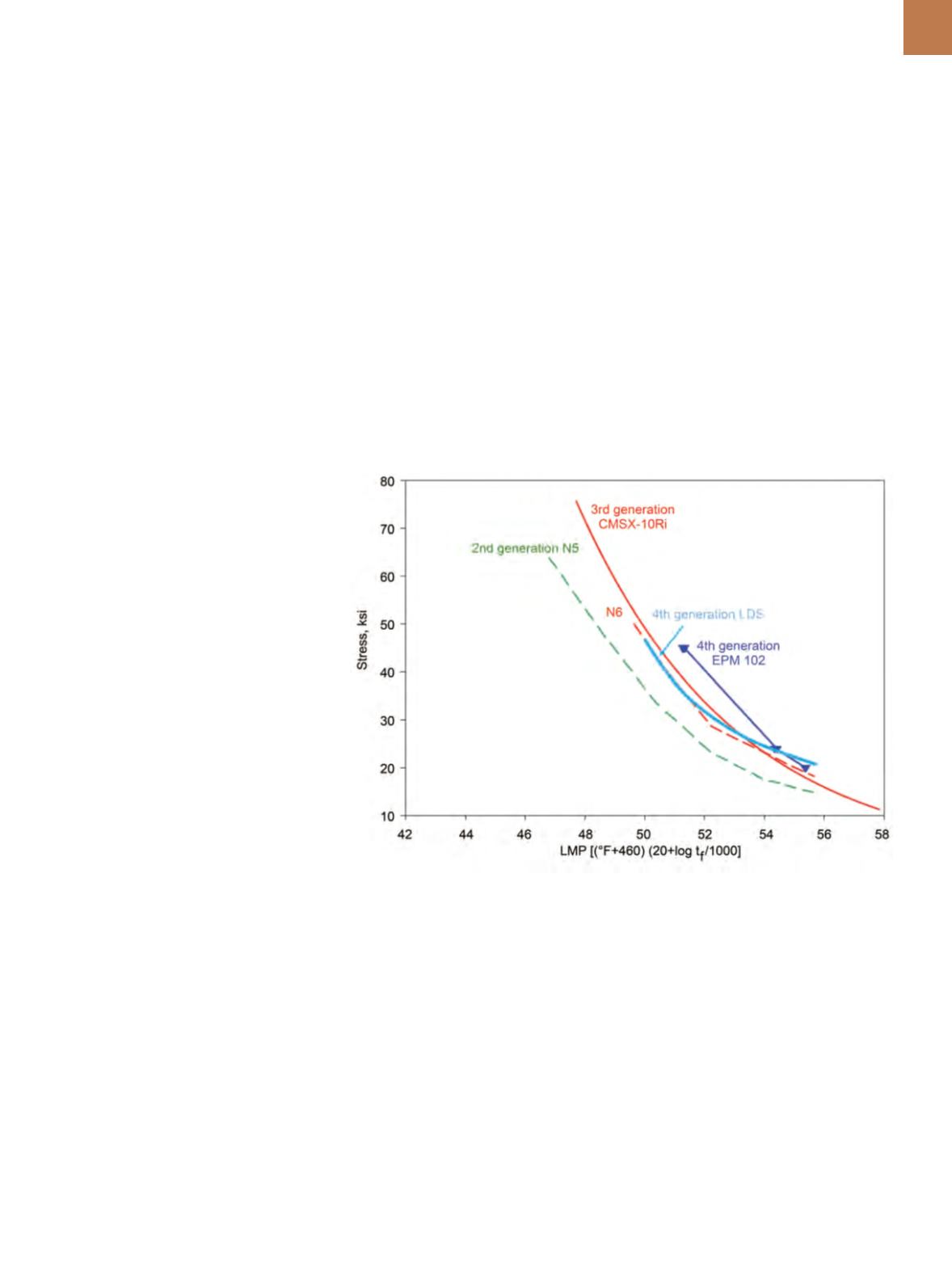

Successive generations of alloys

significantly increased creep strength

together with concurrent increases in

cost and alloy density and decreases in

microstructural stability and environ-

mental resistance (especially in the third

and fourth generations). Further, the

magnitude of improvement in creep re-

sistance with each succeeding genera-

tion diminished as shown in Fig. 1. Alloy

development in recent years has aimed

at reducing density

[1]

and Re levels

[2]

while maintaining current creep resis-

tance rather than increasing it.

Improvements in fuel efficiency

and exhaust emissions expected from

next-generation turbine engines require

further increases in hot sectionmaterials

capability. There is no obvious materials

development strategy available to pro-

duce further improvements in tempera-

ture capability without upsetting the

balance of properties achieved in sin-

gle-crystal superalloys. Higher reliance

on TBCs is a possible strategy, although

the consequences of coating spallation

are still quite serious. One means of mit-

igating the risk of coating spallation is to

incorporate self-indicating features into

the coating system, whereby dopants at

different depths within the topcoat lay-

er have varying luminescence and thus

enable easy inspection for erosion or

spallation

[3]

.

Ceramic-matrix composites (CMCs)

remain the prime candidates to replace

superalloys for ultimate gains in per-

formance, especially at temperatures

above about 1200

o

C. SiC/SiC composites

exhibit substantial improvements inme-

chanical performance

[4]

, and manufac-

turing technology has matured substan-

tially

[5]

. However, risks associated with

CMCs include relatively low strength

Fig. 1 —

Larson-Miller curves for single-crystal superalloys. Improvements in creep strength of

succeeding generations of alloys have diminished.