A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

M A Y

2 0 1 5

1 9

B

ell Helicopter and Harvest selected the EOSINT P 730

for manufacturing aircraft parts after careful study and

testing, focusing on the intertwined technical and financial

benefits. In addition to increased nestability, the larger EOS

build platform provides a number of benefits. For example,

building bigger components in one piece rather than in sec-

tions enables a stronger andmore lightweight part, and also

eliminates some assembly operations.

Another advantage of the EOS system is the clean sur-

face it produces. Some competing AM technologies produce

satisfactory parts, but peripheral heat from the laser beam

melts adjacent powder resulting in unwanted particle adhe-

sion and the need for additional post-processing to polish

the surfaces.

“We were able to achieve the desired quality with the

other additive system,” says Ron Clemons,

director of busi-

ness development at Harvest,

“but there was a lot more fin-

ishing labor associated with it than on the EOS platform.”

The P 730 incorporates a software fix for laser sintering

that provides crisper detail and smoother surfaces.

Switch-

ing to the EOS system offered significant post-processing

cost savings and shorter lead times for Bell Helicopter.

An important secondary benefit of EOS laser-sintering

technology is increased recyclability of the plastic powder.

With other AM processes, breaking out the part from the bed

of powder leaves behind a significant amount of unusable par-

tially melted powder, which must be discarded, so the bulk of

production is performed with virgin powder. The reduction of

waste in the P 730 enables recycling of leftover powder.

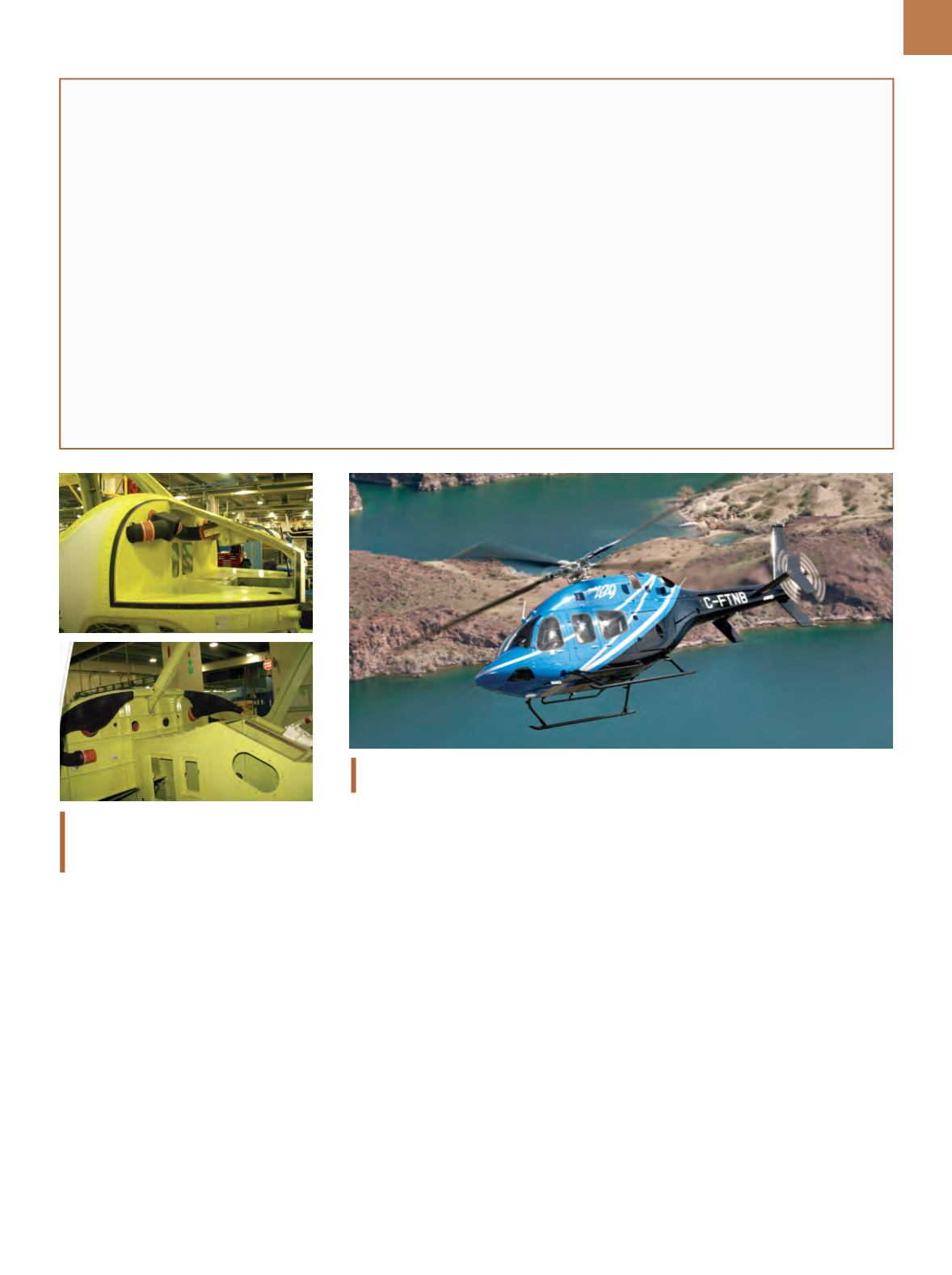

Parts of the environmental control system of the Bell 429 commercial helicopter were pro-

duced using EOS laser-sintering technology.

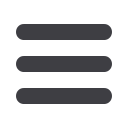

Laser-sintered ductwork installed in a

helicopter airframe. Images on this page

courtesy of Bell Helicopter Textron Inc.

MAKING AIRCRAFT PARTS ON THE EOSINT P 730

mechanical integrity, unique serial IDs

for each part, andmaterial certification.

A preproduction sample is sent to

Bell Helicopter for examination to ensure

that it is functional, fits accurately with

other components, meets engineering

specifications, and that Harvest’s inspec-

tion procedure is correct and complete.

“We have full confidence in Harvest

and their quality assurance program,”

says Schulte. “Once their QA is com-

plete, when warranted, we go to some

lengths ourselves to make sure that the

design intent is also met. We continue

to work with Harvest to streamline pro-

duction and take advantage of additive

manufacturing technology maturation.”

Only when this final scrutiny is complete

does Harvest ship the rest of the pro-

duction batch to Bell Helicopter.

LOOKING AHEAD

Bell Helicopter continues to pro-

pose innovative designs in the form

of CAD models that Harvest turns into

physical parts. In fact, Bell is interested

in using laser-sintered parts throughout

the aircraft systems of its commercial

helicopters. Currently, the company is

mostly using laser-sintered components

in the ECS system, but is starting to in-

corporate laser-sintered hardware into

other assemblies. It will also evaluate

laser sintering of high-temperature

plastics intended for use in more de-

manding roles and environments.

AM is transforming more than the

designs at Bell Helicopter. Engineers are

taking advantage of the freedom that

comes with applying EOS technology,

creating small components, working

with larger ones than in the past, and

using the part-integrating capability of

laser sintering to eliminate assembly

costs.

~AM&P

For more information:

Jessica Neh-

ro is field marketing manager, EOS of

North America Inc., 28970 Cabot Dr.,

Suite 700, Novi, MI 48377, 248.306.0143

ext. 8104,

jessica.nehro@eos-na.com,

www.eos-na.com.