A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

M A Y

2 0 1 5

1 7

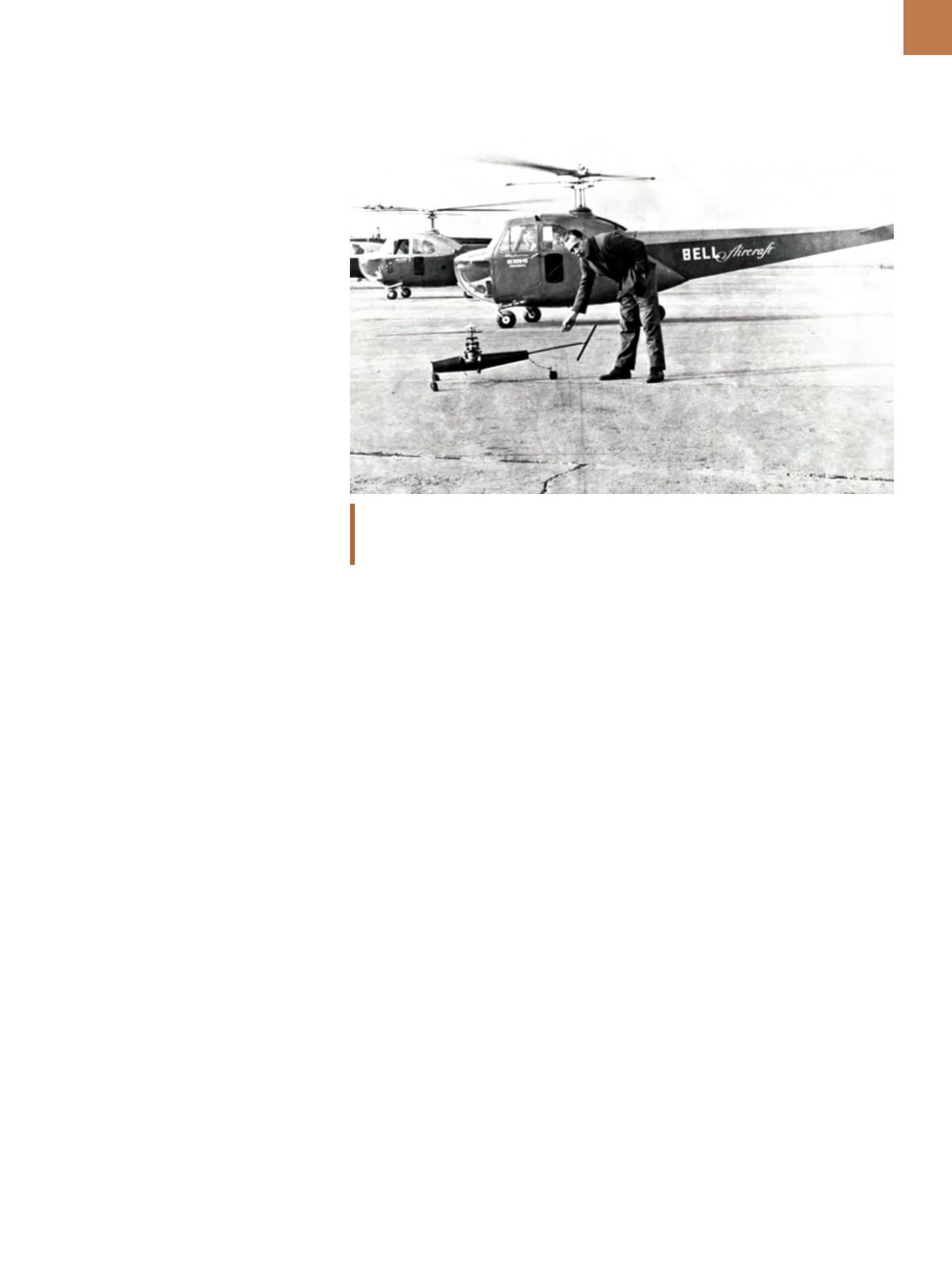

I

n 1941, Arthur M. Young demonstrated

an ingeniously engineered model heli-

copter flying on a tether while working

for Bell Aircraft Corp. Five years later, the

company received the first-ever certifica-

tion for a commercial helicopter. Today,

Bell Helicopter Textron Inc., Fort Worth,

Texas, has manufactured more than

35,000 helicopters. Bell Helicopter works

with Harvest Technologies, Belton, Texas,

an additive manufacturing (AM) services

provider with more than 40 AM systems,

many of them used to create end-use

components and assemblies.

Collaboration between Bell and

Harvest proves that AM is a high quali-

ty, repeatable, and cost-effective man-

ufacturing process, in this case with

plastic laser-sintering technology from

EOS GmbH Electro Optical Systems,

Germany.

LASER SINTERING PRODUCES

3D-PRINTED PARTS

For years, Bell Helicopter and

Harvest have partnered to produce

flight-certified hardware on a standard

laser-sintering platform. Bell believed it

could achieve success with laser sinter-

ing due to its extensive experience qual-

ifying both products and manufacturing

processes, while Harvest has the neces-

sary expertise in AM.

Harvest purchasedanEOSINTP730

plastic laser-sintering system in 2011.

The system features twin 50-W lasers

working in tandem over an expansive

build area—a first for laser-sintering

technology—to achieve a layer-by-layer

build speed of 35 mm (1.38 in.) per hour

of height. The platform offers several

advantages for qualifying this machine

for end-use parts production.

“The parts we get from the P 730

have very good feature definition, and

the powder color is consistently less ox-

idized,” says Harvest quality manager

Caleb Ferrell. “Mechanical properties

are also good. We’re especially happy

with the larger platform size and the

nestability aspect.”

The ample platform size and nesta-

bility contribute to reducing per-unit

cost. The build platformmeasures 700

×

380

×

580 mm (27.5

×

15

×

23 in.), larger

than Harvest’s standard laser-sintering

systems. The increased size enables pro-

duction of more components in a batch

and far more than traditional laser-

sintering platforms, especially when

careful nesting practices are used. Nest-

ing also achieves more cost effective,

low volume production.

For example, Bell Helicopter and

Harvest converted a number of aircraft

parts made using other manufacturing

processes to laser sintering. “A precon-

ception is that additive manufacturing

is more costly compared with alternate

manufacturing methods, with design

flexibility being the premium feature,

but we often discover that production

cost per piece is substantially reduced

using the P 730,” says Elliott Schulte,

Bell Helicopter engineer. (See sidebar.)

VERIFICATION PROCESS

Before production could begin,

Bell Helicopter and Harvest needed to

prove out the P 730 and its processing

capabilities to certify the platform for

use. While the new technological ad-

vances included in the system along

with the sheer platform size provide

greater efficiencies, the companies

needed to ensure this was not at the

cost of part integrity.

The dual laser system and subse-

quent “knit line” presented new consid-

erations to analyze and evaluate. Veri-

fying a new platform meant not only

addressing these factors, but also ex-

amining other common issues such as

heat distribution (part bed temperature

consistency), powder degradation, di-

mensional accuracy, repeatability, part

quality, part performance, and overall

economics of the platform.

Bell Helicopter initially

character-

ized a variety of laser-sinterable Nylon

11s and 12s, for which materials and

manufacturing methods were covered

by company-authored specifications.

The resulting materials characteriza-

tion and properties database ensured

that the P 730 machine qualification

(both system and process) was accom-

plished quickly.

Mechanical properties of each

laser-sintered build were characterized

to confirm that the EOS system met

specification requirements and pro-

duced the same product quality each

time. A number of different material

lots and a series of individual builds

were tested to establish that laser sin-

tering was robust and highly repeatable

for producing identical results.

From concept to reality, Arthur Young poses with his final research model, alongside the

commercially certified Bell Model 47B helicopter. Courtesy of Bell Helicopter Textron Inc.,

circa 1947.