A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A Y 2 0 1 5

1 2

TESTING | CHARACTERIZATION

BRIEFS

Aleris, Cleveland, offers a new 7017 aluminum alloy in North America for commercial

plate and defense uses. After extensive review and testing, the U.S. Army Research

Lab issued MIL-DTL-32505 for use in armor applications. 7017 offers high strength,

good weldability, and corrosion resistance. It is currently used in Europe and Asia on

combat vehicles to achieve superior ballistic protection.

aleris.com.

COMBINED METHODS OFFER

BEST OF BOTH WORLDS

Electron crystallography is rou-

tinely used to solve otherwise intracta-

ble structures. Now, combining powder

diffraction data with electron crystallog-

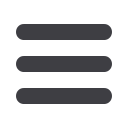

Refined structure of (Pb,Bi)

1-x

Fe

1+x

O

3-y

. Courtesy of Batuk, et al.

a modulation function, the construc-

tion of the structure model is much

more complicated than for nonmod-

ulated materials. While existing tech-

niques can solve this problem from

single crystal diffraction data, another

approach is needed for powder diffrac-

tion data, which is where the work of

Dmitry Batuk and colleagues come in.

Batuk has shown how electron crystal-

lography tools can be used to sidestep

the limitations of powder diffraction

and complement the structure analy-

sis of modulated structures by powder

diffraction. The team investigated a

series of anion-deficient perovskites to

demonstrate proof of principle. In these

materials, modulation arises as a con-

sequence of the presence of crystallo-

graphic shear planes that have an aver-

age periodicity that is not in synchrony

with the materials’ basic periodicity. In

addition, given the advent of research

into perovskites for solar panels and

semiconductor applications, new in-

formation about their structures and

properties is increasingly important.

However, electron crystallography

is unlikely to make x-ray or neutron dif-

fraction redundant any time soon, says

Palatinus, because many materials are

too short lived under the degrading eye

of the electron beam. Further, electron

techniques generally cannot be applied

in situ in chemical reaction environ-

ments nor under pressure, instead re-

quiring near vacuum conditions. “The

key to success lies in exploiting the

synergy between various methods,” he

adds.

www.cas.cz.raphy offers a clearer view of modulated

structures. When performed in an aber-

ration-corrected microscope and com-

bined with spectroscopic techniques, it

can offer unprecedented detail down to

sub-angstrom resolution.

“The result of all this progress is

that electron crystallography provides

answers to more and more questions

that used to be the domain of x-ray or

neutron diffraction, and is especially

useful when the x-ray or neutron ex-

periment needs to be performed on a

powder material, which limits the dif-

fraction information available,” says

Lukas Palatinus of the Czech Academy

of Sciences in Prague.

Palatinus points out that when

confronted with modulated structures,

in which every atomic position is per-

turbed from one unit cell to the next by

NASA

has partnered with five

organizations to provide in-depth

knowledge on composite materials

that could be used to boost aircraft

efficiency. Partners include

Boeing

Research & Technology,

St. Louis;

Lockheed Martin Aeronautics

Co.,

Palmdale, Calif.;

General

Electric Aviation,

Cincinnati; the

Federal Aviation Administration,

Romulus, Mich.

;

and a team from

United Technologies Corp. led by

Pratt & Whitney,

Hartford, Conn.

The consortium was formed in

association with the Advanced

Composites Proje t, part of the

Advanced Air Vehicl s Prog am

in NASA’s Aeronautics Research

Mission Directorate.

nasa.gov.

BRIEFS

Westmoreland Mechanical Testing & Research Ltd.

opened a new

materials testing facility in Oxfordshire, UK. The site is triple the size of

the previous location, Nadcap certified, and UKAS ISO 17025 accredited.

Th facility offers additional fatigue and tensile testing capabilities and

enha ced composites testing. It also features an upgraded metallography

lab, enhanced machining capabilities, and a new lab information man-

agement system.

www.wmtr.co.uk.