A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A Y 2 0 1 5

1 8

Gravelle, leader of Bell Helicopter’s rapid

prototyping lab. For example, it might

not be possible to use the exact config-

uration of bosses made of laser-sintered

nylon for attachment points as those

used for a metal part. Many designs are

treated as a mostly “clean slate,” be-

cause laser sintering provides a great

deal of flexibility and freedom.

After final review of the design for

system producibility, a 3D CAD mod-

el is sent to Harvest with a request for

quote for development of a build strat-

egy. Some questions include: Is the part

large enough to manufacture on its

side, speeding up the build? Should it

be made (or grown) standing vertically

to take advantage of tighter uniformi-

ty and accuracy on the

x

-

y

axis? How

nestable is it, and how many units can

be made in a single build? Answering

these and other questions enables sub-

mitting an accurate pricing quotation.

When production begins, before

each batch, a rigorous checklist of pre-

production inspections (for example, a

nitrogen leak rate check) developed by

Harvest is carried out, which reduces

waste and ensures part quality. The list

is developed specifically for the P 730

based on previous production runs.

Batches of laser-sintered parts

built successively (often left unattend-

ed overnight) are thoroughly inspected

and tested for tensile and flexural prop-

erties. This requirement was estab-

lished by Harvest for process assurance.

Tensile bars are incorporated along the

x

,

y

, and

z

axes of each batch during part

production. If the bars pass the tensile

test, parts built in that batch pass as

well. Harvest also documents manufac-

turing from beginning to end, including

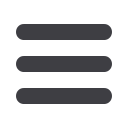

After laser sintering, completed parts

require “breaking out” from the powder.

Excess powder is removed and much of

it reused for subsequent builds.

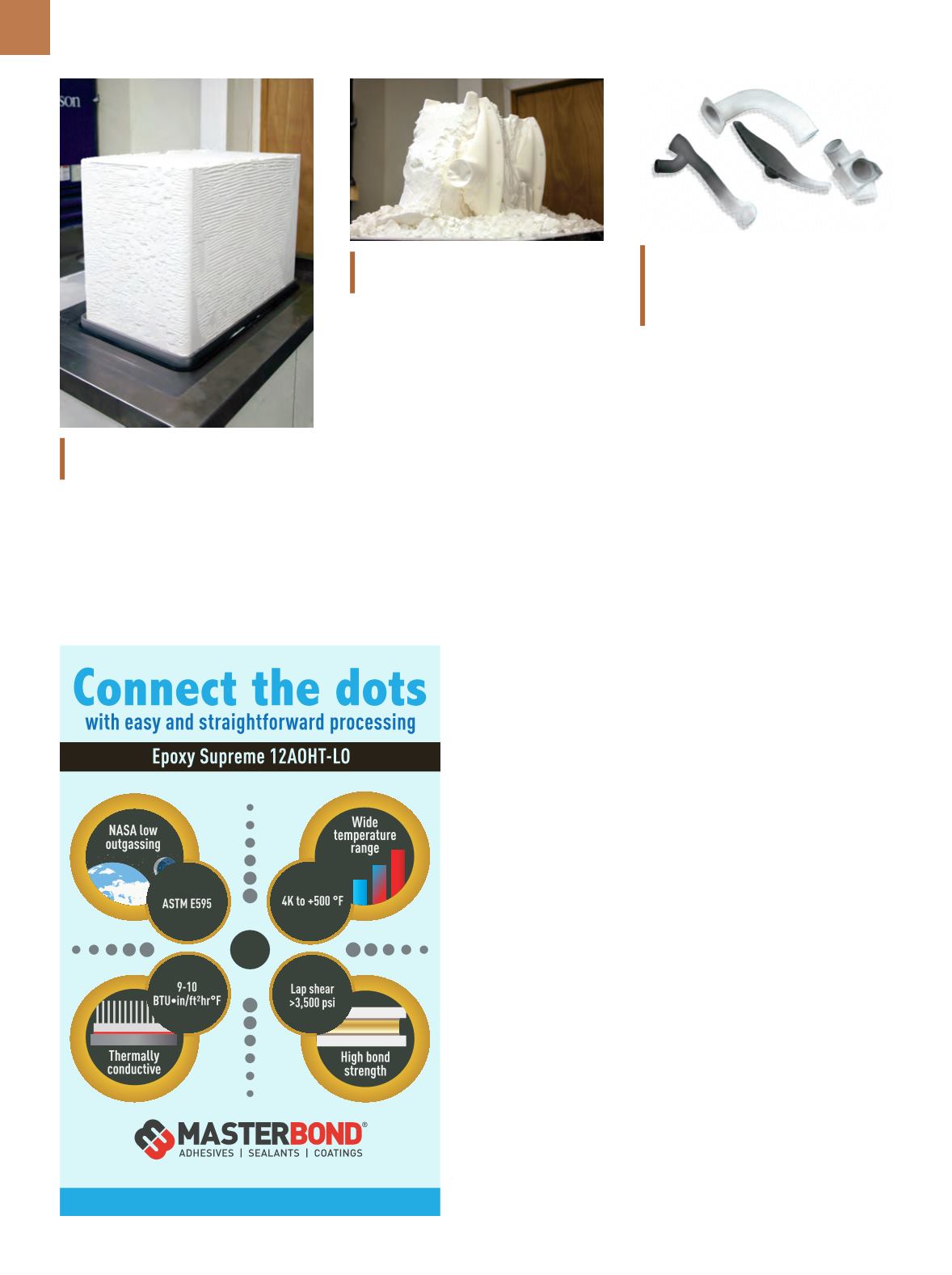

Plastic laser sintering is capable of creat-

ing complex shapes such as ductwork.

Images on this page courtesy of Harvest

Technologies.

periodically reviewing Harvest’s QA

system with respect to AS 9100C—the

SAE quality management standard for

aerospace. After qualifying the AM sys-

tem and nylon materials, Bell Helicop-

ter and Harvest began the meticulous

sequence of manufacturing aerospace

hardware, which involves many checks

and confirmations along the way.

PARTS PRODUCTION

Consider a hypothetical example

of Bell Helicopter wanting to incorpo-

rate a new piece of ductwork into the

environmental control system (ECS) of a

commercial helicopter.

The engineering team

would use the data-

base created to qualify

the P 730 to design a

duct based on specified

mechanical properties.

The part could differ

from an earlier design

by merging several

components into one

(part consolidation), or

by creating its form for

maximum functionality

rather than manufac-

turing demands such as

draft angle for molding,

wall thickness limita-

tions due tomaterial in-

put, or rounded corners

for CNC machining. The

final design must meet

the same performance

specifications.

It is possible that

the redesigned part

could have a different

shape and features, ac-

cording to Christopher

Hackensack, NJ 07601, USA +1.201.343.8983 main masterbond.com www.masterbond.comBell Helicopter also followed its

standard procedure used to audit sup-

pliers, which not only ensures con-

formance to its process specification,

but also serves as a quality audit by