SiC abrasive paper can be used for grind-

ing, resin-bonded diamond discs such as

MD-Piano provide excellent flatness and

long life. Napless cloths are used for di-

amond polishing while low-nap clothes

are used to polish with alumina or colloi-

dal silica abrasives. In most cases, a ret-

icule is used to make the measurement.

Alternatively, many image-capture soft-

ware programs allow operators to make

point-to-point distance measurements.

However, these systems must be proper-

ly calibrated.

Hot working temperatures can

produce ferrite at the surface with the

amount and size of the ferrite grains

growing as carbon loss increases at the

surface. The upper critical tempera-

ture, Ac

3

, of these grains could be above

1600°F, as alloy composition and residu-

al elements influence the Ac

3

of the steel

grade. Spring steels are used as an ex-

ample. If a decarburized specimen is in-

duction hardened, the heating rate to the

austenitization temperature is extremely

fast. To put all of the carbon in solution

(assuming that the steel has a carbon

content of 0.60-0.65%), it is heated to

roughly 1700°-1750°F. As the holding

time is short, perhaps no more than 10 s,

there is little time for appreciable carbon

diffusion and the decarburization depth

after heat treatment is a function of the

as-rolledmill decarburization depth.

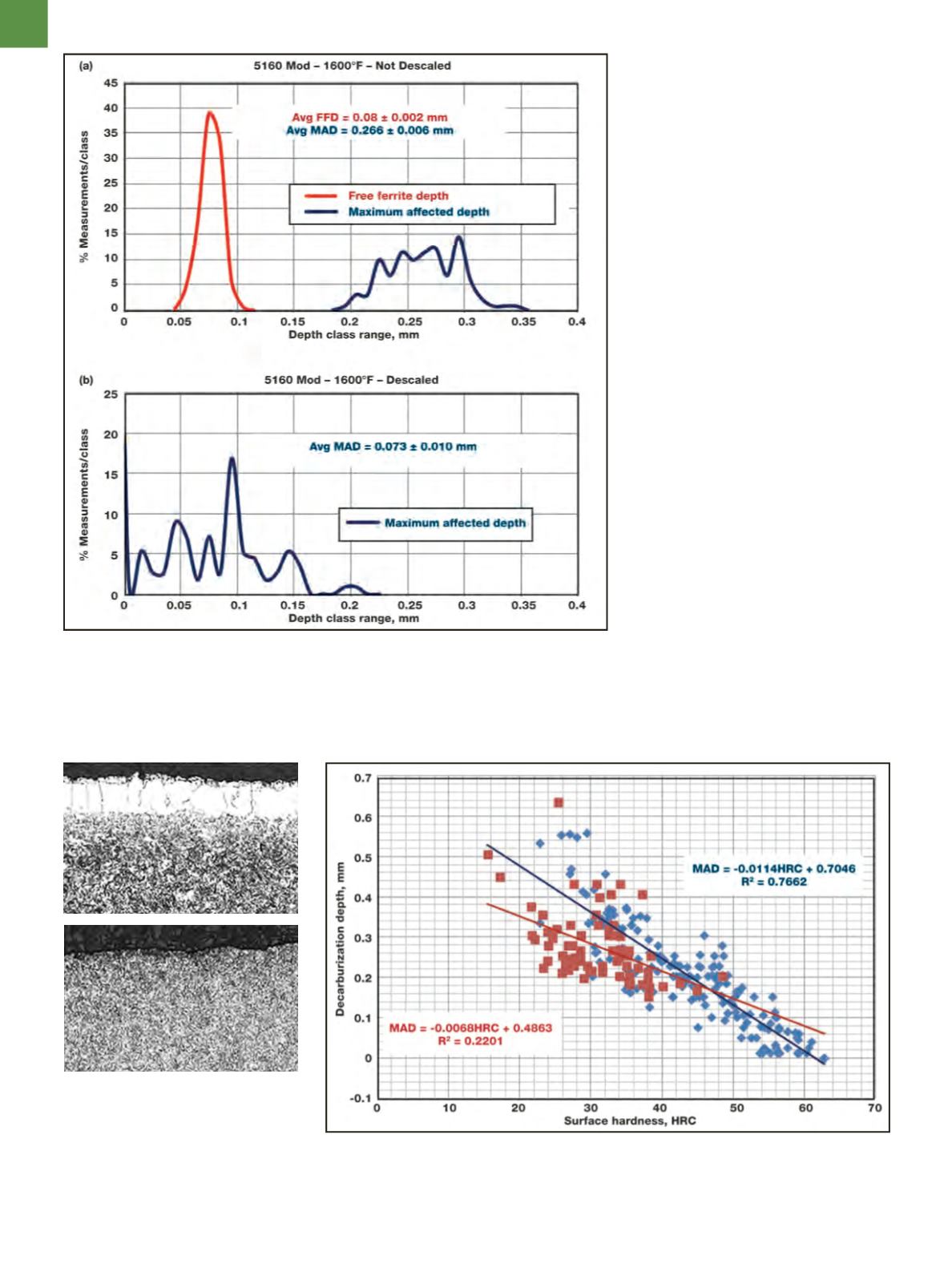

Fig. 4

— Frequency histograms of decarburization measurements made around the periphery

of 5160 modified bars after heat treatment. a) 1600°F specimen with a mill scaled surface has an

average FFD of 0.08 mm and average MAD of 0.266 mm for 132 measurements. Note the narrow,

peaked distribution of the FFDmeasurements and broad distribution of MADmeasurements.

b) 1600°F specimen with a descaled surface does not exhibit any free ferrite. No decarburization

was observed for almost 19.5% of the measurements and distribution of MAD values is broad.

Fig. 5

—Decarburized surfaces of 5160

Mod austenitized at 1600°F for 80 min.

and oil quenched. Free ferrite on the

scale covered specimen, top. No free

ferrite present on the specimen that was

descaled before being austenitized (2%

nital, 200×), bottom.

Fig. 6

—Rockwell C hardness tests on the surface of 5160H, 5160M, and 9260M (after glass bead

blasting) is a simple screening test to determine if the surface is decarburized or free of

decarburization. The correlation is much better when there are no free-ferrite grains at the surface

(blue data points) than when free ferrite (red data points) is present.

A D V A N C E D M A T E R I A L S & P R O C E S S E S | F E B R U A R Y 2 0 1 5

2 4