not present). If free ferrite is present,

the free-ferrite layer’s maximum depth

(often variable) plus the depth of partial

decarburization to the unaffected core

is measured. This total—FFD + PDD—is

called maximum affected depth (MAD).

These depths are not uniform and can

vary substantially, leading to measure-

ments of average FFD, PDD, and MAD,

as well as maximum values for each.

ASTM E1077 covers decarburization

measurement.

In practice, decarburization should

be evaluated on a plane transverse to the

hot working axis, as depth variation is

greater around the bar on the transverse

plane than at a specific constant position

along a longitudinal plane. Decarburiza-

tion depth can vary substantially around

the periphery of a bar, as shown in Fig. 1.

Qualitative measurements can be sub-

jective and biased. Free-ferrite depth

can also be erratic, even over a small sur-

face area, as shown in Fig. 2. Corners of

square or rectangular sections normally

exhibit greater decarburization depths

than planar surfaces. Sampling schemes

for large cross-sections are also illustrat-

ed in ASTM E1077.

To obtain good data, edge reten-

tion must be perfect—the surface must

be perfectly flat to the extreme edge. If

edges are rounded, the exact location

of the outer surface is difficult to define

with precision and depth measurement

accuracy suffers. Good edge retention

requires mounting of the specimen in a

resin, such as DuroFast, that does not ex-

hibit shrinkage gaps between the mount

and specimen after polymerization.

Grinding and polishing procedures must

emphasize maintaining flatness. While

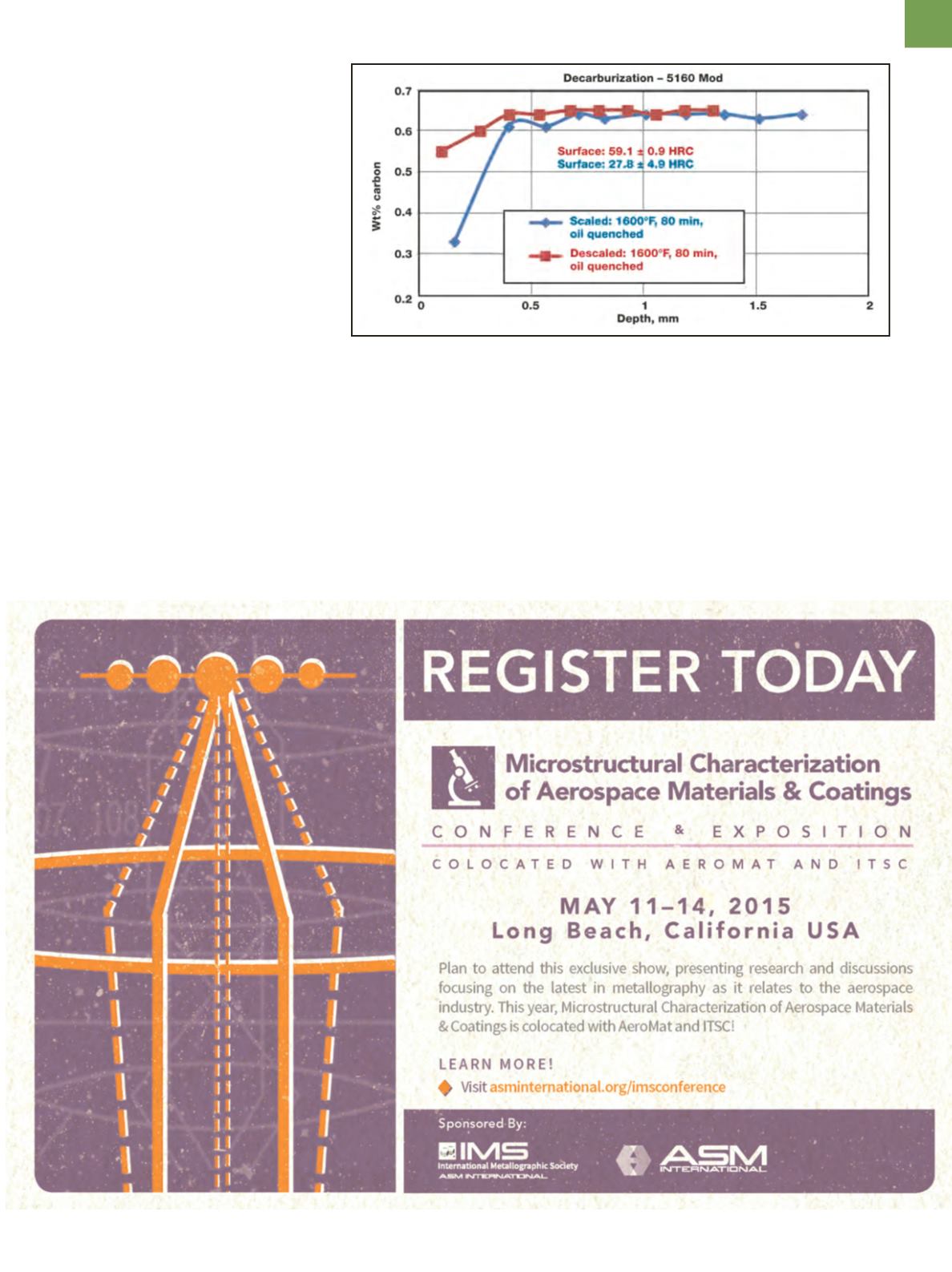

Fig. 3

—Decarburization of 5160 modified spring steel defined by surface hardness and

incremental turnings analyzed chemically for carbon content as a function of whether or not the

surface was descaled or was covered by mill scale, and austenitizing at 1600°F for 80 minutes.

A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | F E B R U A R Y

2 0 1 5

2 3