C

opper-niobium nanolaminates,

composed of alternating layers of

Cu and Nb, display high strengths

(>1 GPa) and intriguing properties due to

their highly oriented nanocrystalline mi-

crostructure. Compared to either pure Cu

or Nb, these composite materials have

superior hardness, flow strength, and

radiation damage resistance

[1-2]

. While

nanolaminates were previously only

available in thin-film form (<40 µmthick),

recent advances in the severe plastic de-

formation process of accumulative roll

bonding (ARB) have enabled production

of bulk nanolaminates (Fig. 1). Four-mm

thick Cu-Nb nanolaminates containing

more than 200,000 individual layers (lay-

er thickness of <20 nm) are now routinely

synthesized for research purposes.

The ability to produce bulk metal-

lic nanolaminates has greatly expanded

the potential structural applications for

these materials, motivating investi-

gations into formability, joining tech-

niques, and deformation behavior. This

article presents an overview of both the

ARB process and the materials’ defor-

mation behavior.

Synthesismethod

The ARB process uses an iterative

sequence of cleaning, stacking, cold roll

bonding, and cutting to create and re-

fine a lamellar microstructure. Starting

materials consist of coarse-grained sin-

gle-phase sheets of Cu and Nb which are

degreased, wirebrushed, and alternately

stacked. Materials are bonded together

using a single-pass 50% rolling reduc-

tion. Next, the roll bonded sheet is cut

in half, cleaned, and re-stacked in prepa-

ration for the next cycle. Iterating these

steps increases the number of layers ex-

ponentially while decreasing layer thick-

ness (Fig. 2). Sheet thicknesses remain

nearly constant during process-

ing, and can be increased by

cutting and bonding three or

more pieces together.

This processing technique

allows extreme strains to be

imparted to the material while

maintaining the desired sheet

thickness. Strains exceed those

typically encountered during

conventional rolling. For exam-

ple, synthesis of 15 nm Cu-Nb

nanolaminates requires a roll-

ing strain of 11.8. Imagine a U.S.

nickel coin (nearly the same

thicknesses as the sheets used

for ARB). If it were convention-

ally rolled to a strain of 11.8, the

length of the rolled strip would

exceed 2 km.

While ARB has been ap-

plied to several different bimet-

al systems

[3-5]

, the Cu-Nb sys-

tem offers low solid solubility

as well as similar flow stresses

for the two phases. These char-

acteristics result in excellent

microstructural stability during

ARB processing, allowing pro-

duction of nanolaminates with

continuous layers and individu-

al layer thicknesses as small as

10 nm

[6]

.

Deformation

behavior

The large dimensions of ARB Cu-Nb

nanolaminates have facilitated a wide

variety of bulk mechanical tests (i.e., ten-

sile tests, miniature Charpy impact tests,

and fatigue tests) that are difficult, if not

impossible, to performon traditional thin

filmnanolaminates. Inmany cases, these

tests confirm the extraordinary proper-

ties of metallic nanolaminates. For ex-

ample, tensile specimens of ARB Cu-Nb

nanolaminates with a 30 nm layer thick-

ness have a strain-to-failure of approx-

imately 8% and a flow strength of 1200

MPa (a 5× increase in strength compared

to pure Cu or Nb)

[7]

. However, bulk me-

chanical testing also reveals an unusual

deformationmode during compression.

During layer-parallel compression

of nanolaminate specimens with layer

thicknesses below100 nm, apronounced

inhomogeneous shape change occurs

A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | F E B R U A R Y

2 0 1 5

1 9

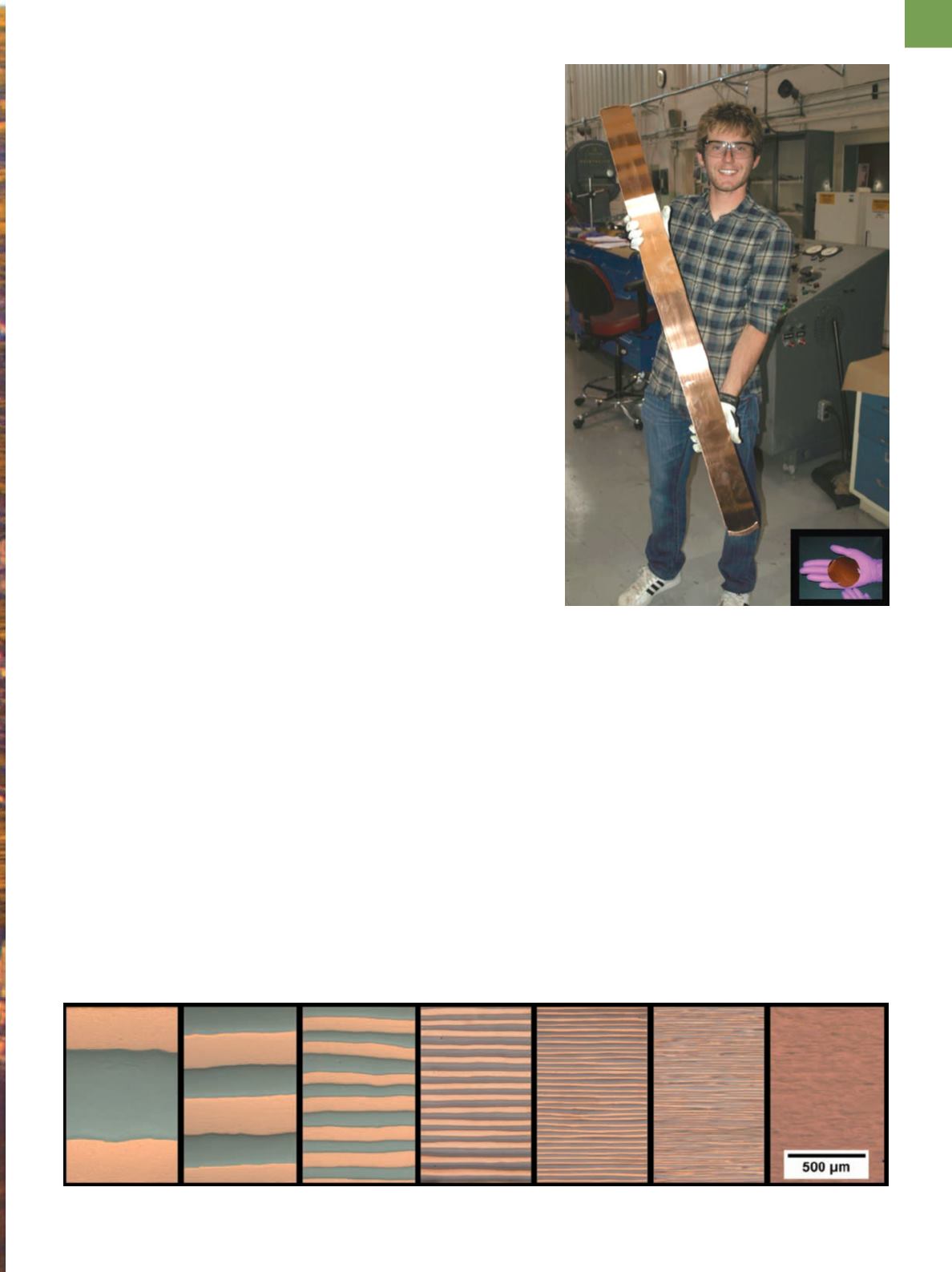

Fig. 1

— A 4-mm-thick piece of Cu-Nb nanolaminate

material synthesized using the ARB process held by

Thomas Nizolek. For comparison, a thin-film Cu-Nb

multilayer synthesized using physical vapor

deposition is shown in the bottom right.

Fig. 2

—Optical micrographs show cross-sections of Cu-Nb laminates at various stages during the ARB process.