A D V A N C E D M A T E R I A L S & P R O C E S S E S | F E B R U A R Y 2 0 1 5

2 6

Additionally, a simple screening

test was used to detect decarburized

specimens of 5160H, 5160M, and 9260M

spring steel lots used for front wheel

drive automobile springs. As the de-

sign loads on these springs increased

throughout the 1970s, no free ferrite

and almost no MAD could be permit-

ted or spring life would be reduced.

Mill processing helped minimize the

MAD to less than the amount removed

in the final processing step of turning

and burnishing. Figure 6 shows data

for a number of specimens where the

surface scan was removed by glass-

bead blasting after hardening and bulk

Rockwell C tests were made on the OD

surfaces at a number of locations and

averaged. Bars were sectioned, me-

tallographically prepared, and rated

for maximum free-ferrite depth (when

present) and maximum affected depth

of decarburization. The plot shows a

much better correlation between HRC

and MAD when free ferrite was not pres-

ent versus when it was present.

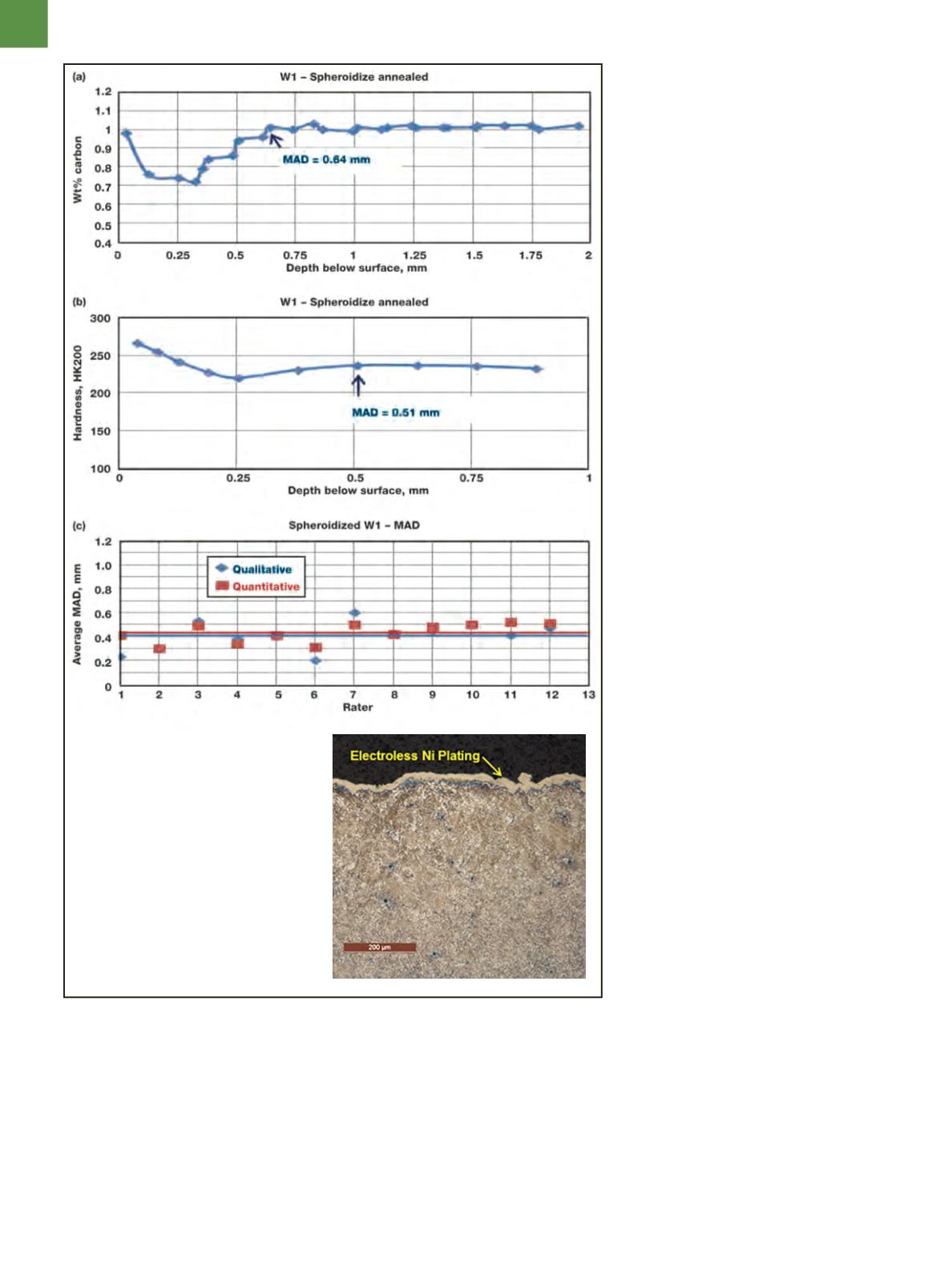

Examples of the variation in decar-

burization ratings by three methods—

carbon analysis of incremental turnings,

microindentation hardness traverses,

and visual qualitative or quantitative es-

timates by light microscopy—are shown

in Fig. 7. The spheroidize annealed mi-

crostructure of W1 carbon tool steel

(~1% C), a typical specimen rated by mill

metallurgists in plants that make tool

steel, is shown in Fig. 7d at 100×. The

carbide in the decarburized surface zone

exhibits a significantly lower volume

fraction than the interior. At the extreme

surface, individual carbides can be seen.

Note the seemingly unusual carbon dis-

tribution at the surface in Fig. 7a. The

lowest carbon content is only to about

0.7%, roughly a 30% loss. So, free fer-

rite is not present. Examination at 1000×

shows that the cementite in the decarbu-

rized zone is not well spheroidized but

tends to be lamellar. This is because the

annealing cycle cannot spheroidize ce-

mentite in the lower carbon surface area

compared to the bulk carbon content.

Note that the hardness at the surface of

the decarburized zone is actually greater

than in the core, a result that may seem

counterintuitive. However, as some tool

steel metallurgists are aware, coarse

lamellar carbide structure—even with a

lower volume fraction than the spheroid-

ized core—is harder and less ductile.

Carbon analysis of the incremental

turningsprovides thebest estimateof the

maximum affected depth. The MAD esti-

mate is more accurate using the Knoop

traverses than LOMmeasurements, but is

still rather conservative compared to the

MAD from actual carbon analysis. How-

ever, this is not amajor problembecause

the hardness became essentially con-

stant at a shallower depth than shown

by the incremental carbon analysis. The

qualitative estimates, based on a simple

visual estimate going around the bar’s

periphery, are slightly lower than the

Fig. 7

—Decarburization

measurements on a spheroidize

annealed bar of W1 carbon steel.

a) Carbon analysis of incremental

turnings reveal a MAD of 0.64 mm.

b) A 200 gf Knoop hardness traverse

reveals a MAD of 0.51 mm.

c) Qualitative and quantitative visual

LOM estimates yield MADs of 0.406 and

0.433 mm, respectively. d) LOM image

of a typical surface area.

(d)