New calibration service tunes high-power lasers

The National Institute of

Standards and Technology

(NIST), Gaithersburg, Md.,

launched a new calibration

service for high-power lasers

used by manufacturers for ap-

plications such as cutting and

welding metals, as well as by

the military for more special-

ized applications like defusing

unexploded land mines. The

new service is offered for

power levels up to 10 kW.

NIST recently completed its

first high-power calibration,

for a commercial 5 kW laser power meter. The measurement had an uncertainty of about

1% over two standard deviations, the accuracy and precision threshold necessary for mil-

itary and advanced manufacturing applications.

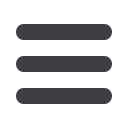

“That level of uncertainty at multi-kilowatt levels is unprecedented,” says calibration

leader Josh Hadler. Exact laser output must be known to achieve effective, safe perform-

ance in virtually all applications at these power levels. To establish the new service, a 10 kW

fiber laser was purchased and a laboratory was extensively renovated to meet electrical re-

quirements and add appropriate safeguards such as walls with high damage tolerance and

special optics and beam controls for the laser. Running lasers are viewed from behind a

protective barrier, using a multi-camera system for monitoring and control. Laser light is

absorbed by a conventional calorimeter surrounded and cooled by flowing water. The tem-

perature difference between incoming and outgoing water is measured and used to calcu-

late laser power.

The new facility will also be used for research on the fundamental physical processes that

occur during laser welding. The study aims to overcome technical challenges such as weld-

ing of materials that are dissimilar or have different thicknesses. Further, the ability to join dis-

similar materials with vastly different properties could help overcome longstanding design

and cost hurdles associated with welding.

nist.gov/pml/div686/calibrations/laser.cfm.Specialized microscope captures nanotube defects

University of Oregon chemists devised a way to see the internal structures of electronic

waves trapped in carbon nanotubes (CNTs) by external electrostatic charges. CNTs are

touted as exceptional materials with unique properties that allow for extremely efficient

charge and energy transport, with the potential to enable more efficient types of electronic

and photovoltaic devices. However, these traps, or defects, in ultrathin nanotubes can com-

promise their effectiveness. Using a custom-built microscope capable of imaging matter at

the atomic scale, researchers are able to visualize the traps, which can adversely affect the

flow of electrons and elementary energy packets called excitons.

According to physical chemistry professor George V. Nazin, the

study modeled the behavior often observed in carbon nanotube-based

electronic devices, where electronic traps are induced by stochastic ex-

ternal charges in the immediate vicinity of the nanotubes. The exter-

nal charges attract and trap electrons propagating through nanotubes.

“Our visualization should be useful for developing a more accurate pic-

ture of electron propagation through nanotubes in real-world applica-

briefs

NSL Analytical Services Inc.,

Cleveland, an independent

commercial testing laboratory,

received

renewed

accreditation

for ISO/IEC 17025. The

accreditation certificates from

ACLASS,

the ILAC-approved

accreditation body for NSL, are

available for download at

nslanalytical.com/accreditations.A research group led by Kazuhiro

Hono at the

National Institute for

Materials Science,

Tsukuba,

Japan, synthesized a new

magnetic compound that requires

fewer rare earth elements than the

currently used neodymium iron

boron compound. The ratio of

neodymium, iron, and nitrogen in

the new compound, NdFe

12

N, is

1:12:1. Its neodymium

concentration is 17% compared to

27% for Nd

2

Fe

14

B, the main

component used in the strongest

permanent magnets. Further, the

new compound’s intrinsic hard

magnetic properties were found to

be superior to those of Nd

2

Fe

14

B.

www.nims.go.jp/eng.Bruker Corp.,

Fremont, Calif.,

completed

divestiture of its gas

chromatography

(GC) and GC single-quadrupole

(GC-SQ) mass spectrometry

products to

Techcomp Europe

Ltd.,

a subsidiary of Techcomp

(Holdings) Ltd, on October 31.

Techcomp will continue to

manufacture the former Bruker GC

and GC-SQ Scion products in the

Fremont factory previously

occupied by Bruker’s Chemical and

Applied Markets division.

Bruker will continue to

provide service and

support for all GC and

GC-SQ products

worldwide.

bruker.com.

ADVANCED MATERIALS & PROCESSES •

NOVEMBER-DECEMBER 2014

8

T

ESTING

C

HARACTERIZATION

news

industry

NIST’s new calibration service for high-power lasers is

controlled from behind a protective barrier. Paul Williams (left)

and Joshua Hadler operate the service, which can calibrate

lasers with up to 10 kW of power for manufacturers and

military customers. Courtesy of Burrus/NIST.

University of Oregon professor George Nazin uses a scanning tunneling

microscope fitted with a closed-cycle cryostat to uncover traps, or defects,

that disrupt electronic waves in nanotubes.