The Center for Heat Treating Excellence

(CHTE) at Worcester Polytechnic Institute

(WPI) in Massachusetts is conducting a

cutting-edge research project aimed at

measuring the surface hardness and case depth on carburized

steels for process verification and control. The results will enable

companies to improve the quality of heat-treated products faster

and more cost-effectively.

“This is the first time a project like this is being undertaken,” ex-

plains Lei Zhang, CHTE researcher and Ph.D. candidate at WPI. “Our

focus is on developing new measurement techniques that will en-

hance product quality.”

According to lead researcher Richard Sisson, Jr., George F. Fuller Pro-

fessor of Mechanical Engineering at WPI, and CHTE director, the heat

treating industry needs rapid, accurate nondestructive techniques to

measure surface hardness and case depth on carburized steels for

process verification and control. “Current measurement methods re-

quire destructive testing with traveler specimens that cannot always

represent the configurations of the production part, nor the associated

subtleties of thermal history, carbon atmosphere, and geometry influ-

enced diffusion. Our research will eliminate much of the guesswork.”

Another industry challenge with the traveler specimen-measure-

ment method is that it often requires periodic sectioning of pro-

duction parts to validate the hardness and case depth after car-

burization, especially for critical shaft and gear teeth configura-

tions. “This method is labor intensive, expensive, and susceptible

to operator error, as well as counterintuitive to the end result of

high quality, usable heat-treated parts,” explains Sisson.

A key challenge of the project is to distinguish between hard-

ness and residual stress, because most techniques currently used

to measure case depth are not only sensitive to hardness distri-

bution, but also to residual stress distribution.

Nondestructive techniques being evaluated initially include eddy

current, meandering winding magnetometer (MWM), Barkhausen

noise testing, and alternating current potential drop.

The project focuses on four tasks:

• Identify nondestructive techniques to measure surface

hardness and case depth and develop a fundamental

understanding of their mechanisms. Select nondestructive

techniques for testing based on project objective and

equipment availability.

• Select alloys and design heat treating conditions to be used

to create testing standards using the simulation method,

and fabricate and characterize the standards.

• Conduct nondestructive tests to determine the correlations

between the destructive test results and the known results

in the standard.

• Determine correlations among nondestructive test

measurements, hardness, and microstructure for the

standards. Verify the effectiveness of the respective

nondestructive test technique in industry.

Completion of the research project is expected in 2016.

ADVANCED MATERIALS & PROCESSES •

NOVEMBER-DECEMBER 2014

40

Breakthroughs in Nondestructive Measuring Techniques

HTPRO

6

About CHTE

The CHTE collaborative is an alliance between the industrial sec-

tor and university researchers to address short-term and long-

term needs of the heat-treating industry. Membership in CHTE is

unique because members have a voice in selecting quality re-

search projects that help them solve today’s business challenges.

Member research process

Research projects are member driven. Each research project has

a focus group comprising members who provide an industrial

perspective. Members submit and vote on proposed ideas, and

three to four projects are funded yearly. Companies also have

the option of funding a sole-sponsored project. In addition,

members own royalty-free intellectual property rights to precom-

petitive research, and are trained on all research technology and

software updates.

CHTE also periodically undertakes large-scale projects funded

by the federal government or foundations. These endeavors

keep members informed about leading edge technology.

CHTE current research portfolio

Other projects now in progress include:

• Improving Alloy Furnace Hardware Life

• Induction Tempering

• Gas Quench Steel Hardenability

• Cold Spray Nanomaterials (supported by ARL)

For more information about CHTE, its research projects, and

member services, visit

wpi.edu/+chte, call 508.831.5592, or

email Rick Sisson at

sisson@wpi.edu, or Diran Apelian at

dapelian@wpi.edu.

l

l

l

l

l

l

l

l

l

l

1.2

1

0.8

0.6

0.4

0.2

0

Slope ratio

0.6 0.7 0.8 0.9 1 1.1 1.2 1.3

Case depth, mm

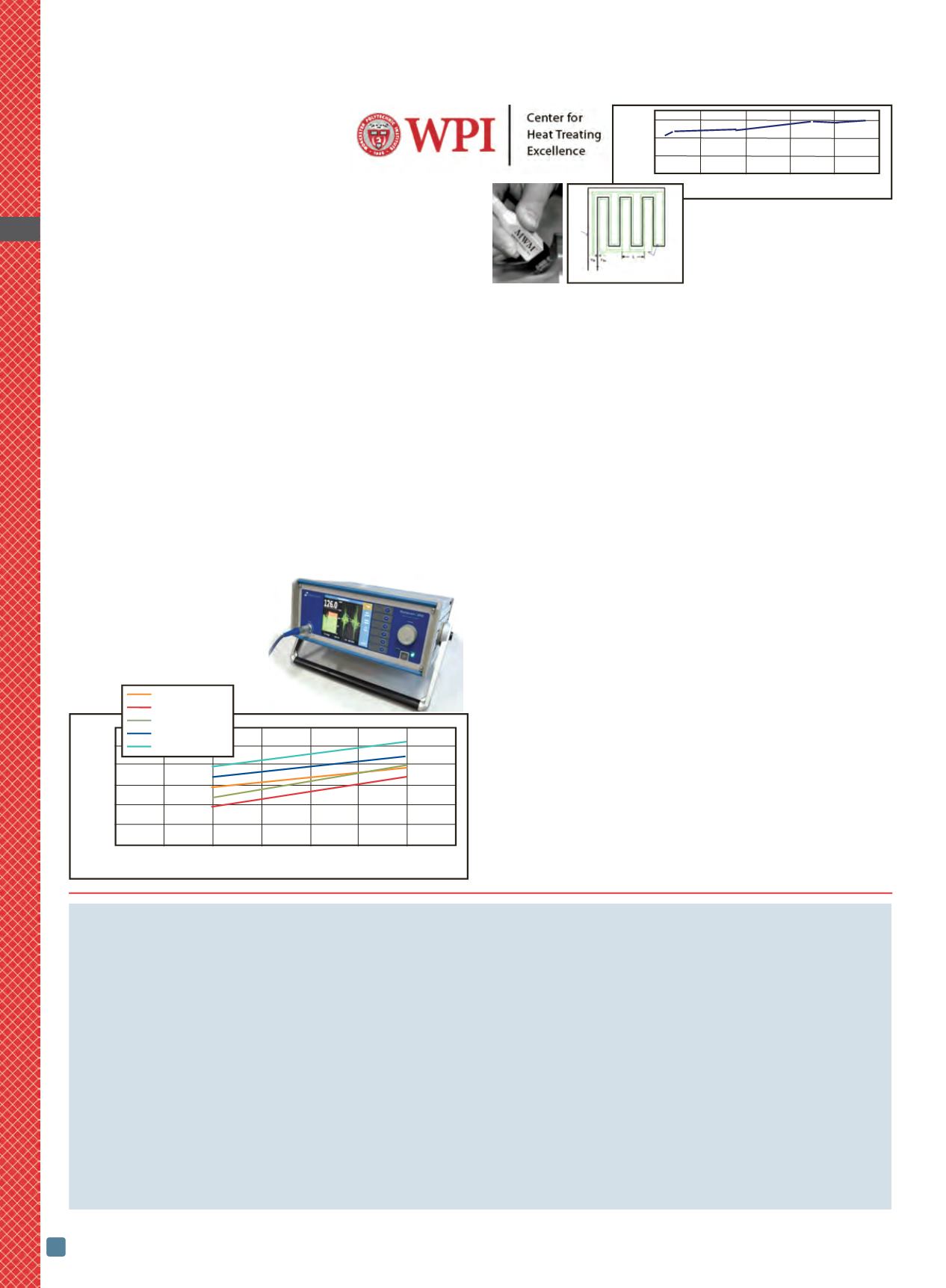

Barkhausen noise unit used

to measure case depth. The

magnetization voltage

sweep method has been

applied, and the slope ratio

reflects the case depth

variation of the tested part.

8 Hz/20 Hz

8 Hz/128 Hz

8 Hz/250 Hz

20 Hz/128 Hz

20 Hz/250 Hz

Primary winding

Secondary

windings

l

l

l

l l l

39.0 41.0 43.0 45.0 47.0 49.0

Permeability

Meandering winding magnetometer

(MWM) used to measure surface

hardness. At a high frequency

(5 MHz), permeability measured by

the MWM sensor has good

correlation with surface hardness.

y

= 16.018

x

= 177.11

600

400

200

Microhardness,

Hv