ADVANCED MATERIALS & PROCESSES •

MAY 2014

37

biocompatibility data on your finished parts.”

Once all that “stuff” is out of the way, the lifecy-

cle of a patient-specific cranial implant starts with

the patient. If someone comes to the hospital with a

skull injury, a CT or MRI scan is performed and pro-

duces a slice file similar to data used to build parts

via laser sintering.

That slice file is then sent to OPM where 3D de-

sign software is used to create an implant that pre-

cisely fits the patient’s anatomy. The implant is then

printed or “grown.” This “growing” phase is entirely

automatic—the laser-sintering system lays down a

thin layer of powder on its build platform. Guided by

the lowest slice of the implant design file, a high-tem-

perature laser melts a cross section of the implant.

When that layer is done, the build platform lowers,

and a new powder layer is distributed on top of the

old one, and the laser melts the next cross section.

The process repeats until the entire implant is built.

Laser sintering is capable of producing practically

any shape geometry to match the precise needs of in-

dividual patients.

When the implant is removed from the leftover

powder (Fig. 4), it must be inspected for quality. In

addition to mechanical and analytical testing, a struc-

tured light scanner is used to do 100% line-of-sight

metrology inspection to certify its dimensional accu-

racy. Finally, the implant is shipped to the hospital.

“The total process from receiving the data to ship-

ping the implant takes less than two weeks,” accord-

ing to DeFelice. (Figs. 5 and 6).

More implant types possible

Having successfully created and obtained clear-

ance for their cranial product, OPM is making plans

to move throughout the body to use the technology.

OPM will only operate in highly regulated, high-risk

markets such as medical. “We are after critical parts,

and biomedical is the pinnacle of that,” DeFelice says.

“That means you need the right material, the right

process, the right quality system, and the right

metrology. When the patient is on the operating table

and the part shows up and doesn’t fit, you are putting

someone’s life at risk. With the first implant case,

where the implant was very large, extensive areas of

critical tissues were exposed during surgery. Every

second is critical in that situation.”

For more information:

Scott DeFelice is president and

CEO of Oxford Performance Materials (OPM), 30 South

Satellite Rd., South Windsor, CT 06074, 860/698-9300,

www.oxfordpm.com.

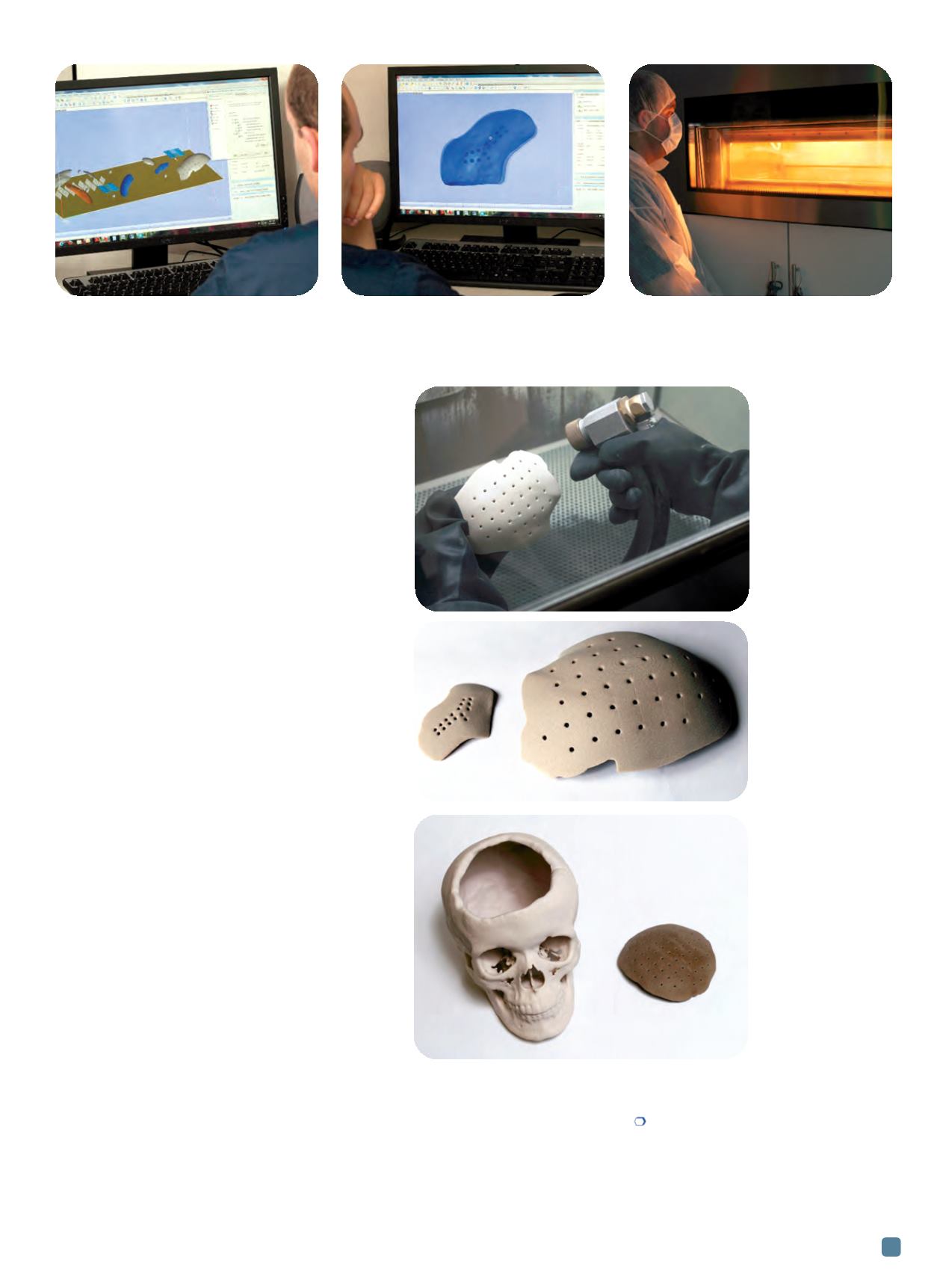

Fig. 1 —

A batch of implants are set up for

production. The EOSINT P 800 system can

run multiple, different designs in a single

build. All images are courtesy of Fred Smith

Associates.

Fig. 2 —

3D digital model of a cranial

implant.

Fig. 3 —

Using patient-specific 3D digital

data, the cranial implant is additively

manufactured with an EOSINT P 800

high-temperature plastic laser-sintering

system.

Fig. 4 —

The completed part

is cleaned of any

residue powder.

Fig. 5 —

Cleaned implants.

Fig. 6 —

Skull model

demonstrates how

an implant is

customized to fit the

cranial hole.