ADVANCED MATERIALS & PROCESSES •

MAY 2014

41

4-6% chromium (manganese was no longer used),

and 10-20% tungsten.

Mathews was granted a patent in 1905 for the ad-

dition of vanadium to high-speed steel. With the ad-

dition of about 1% vanadium to the 18% tungsten, 4%

chromium, and 0.60-0.80% carbon steel, the first

truly universal high-speed steel was born. By 1905,

the “18-4-1 high-speed steel” was in commercial pro-

duction and would remain the major tool steel for

metal machining during the next 35 to 40 years.

Metallurgical research moves forward

One of the first research studies on high-speed

steels was by H.C. Carpenter of England, who believed

that the high-temperature phase (austenite) was the

source of red hardness. He was led into this error due

to the large amount of austenite he found in samples

after cooling from the hardening temperatures.

Another British metallurgical research study un-

dertaken by C.A. Edwards and H. Kikkawa provided

the first comprehensive understanding of the major

metallurgical phenomena in high-speed steel. They

concluded that chromium imparts the self-hardening,

and that the extremely high hardening temperature was

needed to dissolve the tungsten. Maximum resistance

to tempering can only be ob-

tained by getting the tungsten

into solution. They also con-

cluded that careful tempering

studies with hardness measure-

ments could provide valuable

information on the relative

merits of cutting tools.

Shortly after Edgar Bain’s

early work using x-rays to de-

termine the crystal structure of

austenite (fcc), ferrite (bcc), and

martensite (bcc), he and Zay

Jeffries, while working at the

GE Lamp Division, published

their famous paper in

Iron Age

in 1923 on the “Cause of Red

Hardness of High Speed Steel.”

This paper is considered

a classic in the field of metals

technology, not because it

changed industrial practices, but because it combined

the latest research tool (x-ray diffraction) with the

most recent theory of hardening—slip interfer-

ence by precipitated particles. This paper showed,

as concluded earlier by Edwards and Kikkawa,

that the high hardening temperatures are needed

to dissolve the particles of tungsten-containing

carbide in the austenite. Bain and Jeffries then

concluded that the softening of hardened steel

during tempering, which occurs in ordinary steel

at low temperatures (300° to 900°F), is caused by

grain growth and carbide particle growth beyond

the critical size. They reasoned that the greater

stability of the tungsten carbide forces its forma-

tion at 1000° to 1200°F, where it increased the

hardness to a peak called “secondary hardening.”

It is only at these temperatures that the larger

tungsten atoms can move within the iron space

lattice to form the alloy carbides. Later studies

would confirm the thrust of their theories, al-

though the details of alloy carbide formation

would be more complex in detail.

The following year, 1924, Edgar Bain moved from

General Electric Co. to Atlas Steel Co. in Dunkirk,

N.Y., where he worked with one of America’s most

interesting and prolific metallurgists, Marcus A.

Grossmann. The publications of Bain and Gross-

mann in 1924 included high-carbon, chromium

steels, chromium in high-speed steel, and their major

work, “On the Nature of High Speed Steel,” which

they published in Great Britain in the

Journal of The

Iron and Steel Institute.

This paper was a compilation

of the arts on the manufacturing and metallurgy of

high-speed steel. In some ways, it appears to be a

combination of Grossmann’s practical knowledge

with the metallurgy and theory reported earlier by

Bain and Jeffries. Grossmann and Bain expanded this

effort in their collaboration in 1931 with the publica-

tion of a textbook entitled “High Speed Steel.”

For more

information:

Charles R. Simcoe

can be reached at

crsimcoe@yahoo.com.

For more metallurgical

history,

visit

www.metals- history.blogspot.com.

Edgar Bain, a

research

metallurgist who

worked with Marcus

Grossman to publish

research studies

and a book on high-

speed tool steels.

Courtesy of Library

of Congress/U.S.

public domain.

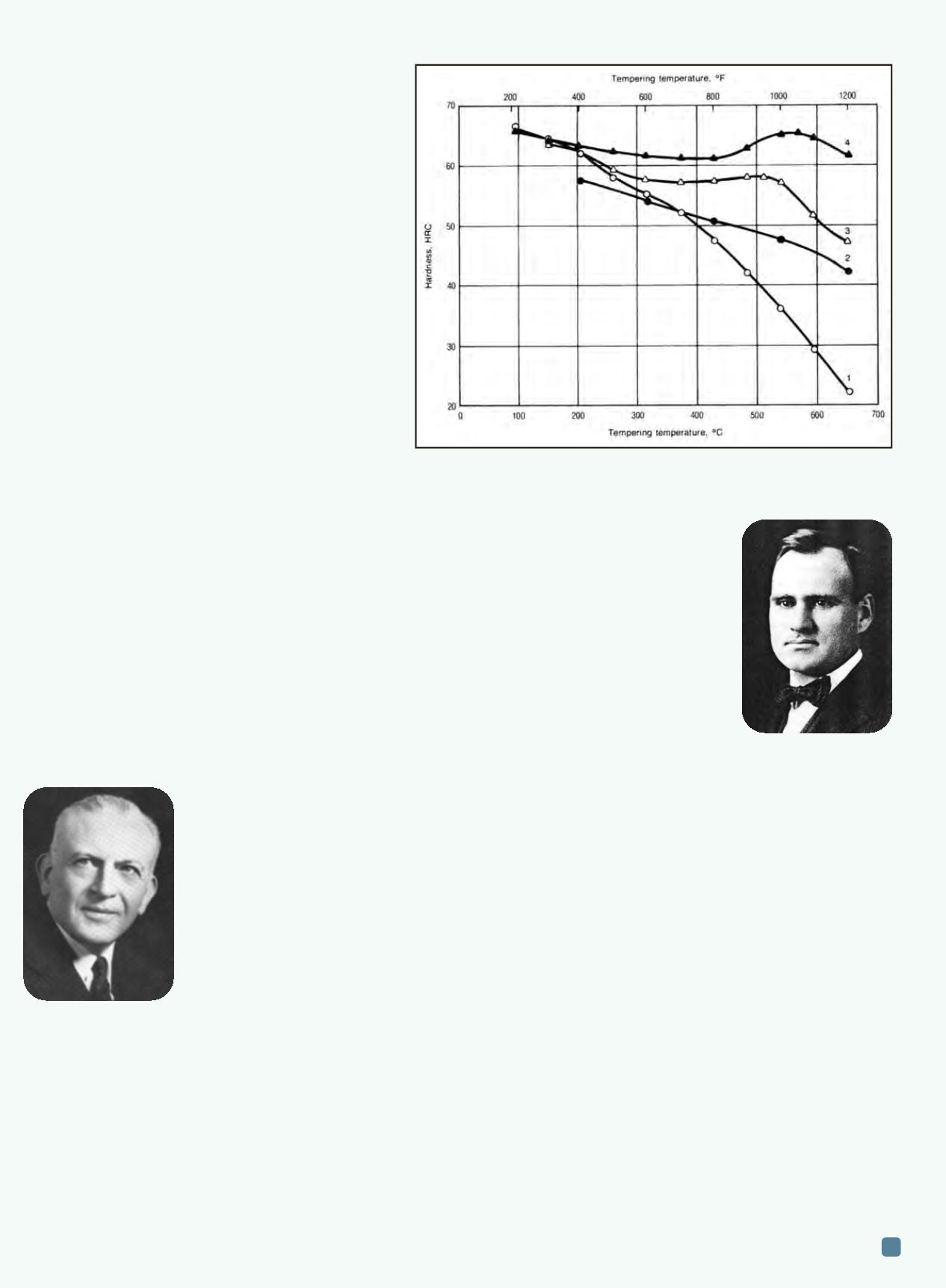

Variation of hardness with tempering temperature for four typical tool steels. Cour-

tesy of Wrought Tool Steels, Properties and Selection: Irons, Steels, and High-Per-

formance Alloys, Vol 1, ASM Handbook, ASM International, 1990.

Zay Jeffries (pictured)

published on the theory

of red hardness in high-

speed tool steels with

Edgar Bain and served as

ASM president in 1929.

Courtesy of ASM

International.