55°C for about 12 hours, and

then cycled between roughly

5° and 20°C during the

EOIM-3 exposure period. Sputtered films of pure MoS

2

[5]

representing the historical, columnar growth morphol-

ogy typical of undoped films were evaluated alongside

structurally modified films that were co-sputtered with

antimony oxide (MoS

2

/Sb

2

O

3

)

[6]

, or deposited in multi-

layers with nickel (MoS

2

/Ni)

[7]

. In addition to LEO expo-

sure, films were also exposed in a terrestrial facility

[8]

using AO energy per atom and UV exposures designed

to emulate the LEO environment. In this case, films expe-

rienced an AO fluence of 1.97×10

20

atoms/cm

2

(about 15%

less than in the space flight) during an exposure of 25.28

hours. Several identical sets of samples were produced for

EOIM-3 so that samples could be examined after LEO ex-

posure, after AO exposure in the laboratory, and after des-

iccated storage on earth for the

same time period.

More recently, a compos-

ite MoS

2

film was exposed to

LEO during the Materials on

the International Space Sta-

tion-7 (MISSE-7) experiment.

Samples were installed on the

ISS on November 23, 2009,

during STS-129 (another At-

lantis mission), and recovered

on March 1, 2011, during

STS-133 (shuttle Discovery),

accumulating 463 days of

exposure. MISSE-7 samples

were exposed to 3.60×10

21

atoms/cm

2

, roughly 14.4 times the total fluence of the

earlier EOIM-3 experiment. Composite MoS

2

films were

co-sputtered with antimony oxide and gold

(MoS

2

/Sb

2

O

3

/Au)

[9]

, and were enclosed in “suitcase style”

passive experiment containers (PECs), shown in Fig. 1, as

part of Sandia’s Passive ISS Research Experiment (SPIRE)

on MISSE-7. These LEO exposure experiments were con-

sidered passive, while active experiments were led by B.

Krick and W.G. Sawyer at the University of Florida, where

data from sliding wear tests was collected on orbit and

downloaded directly from space.

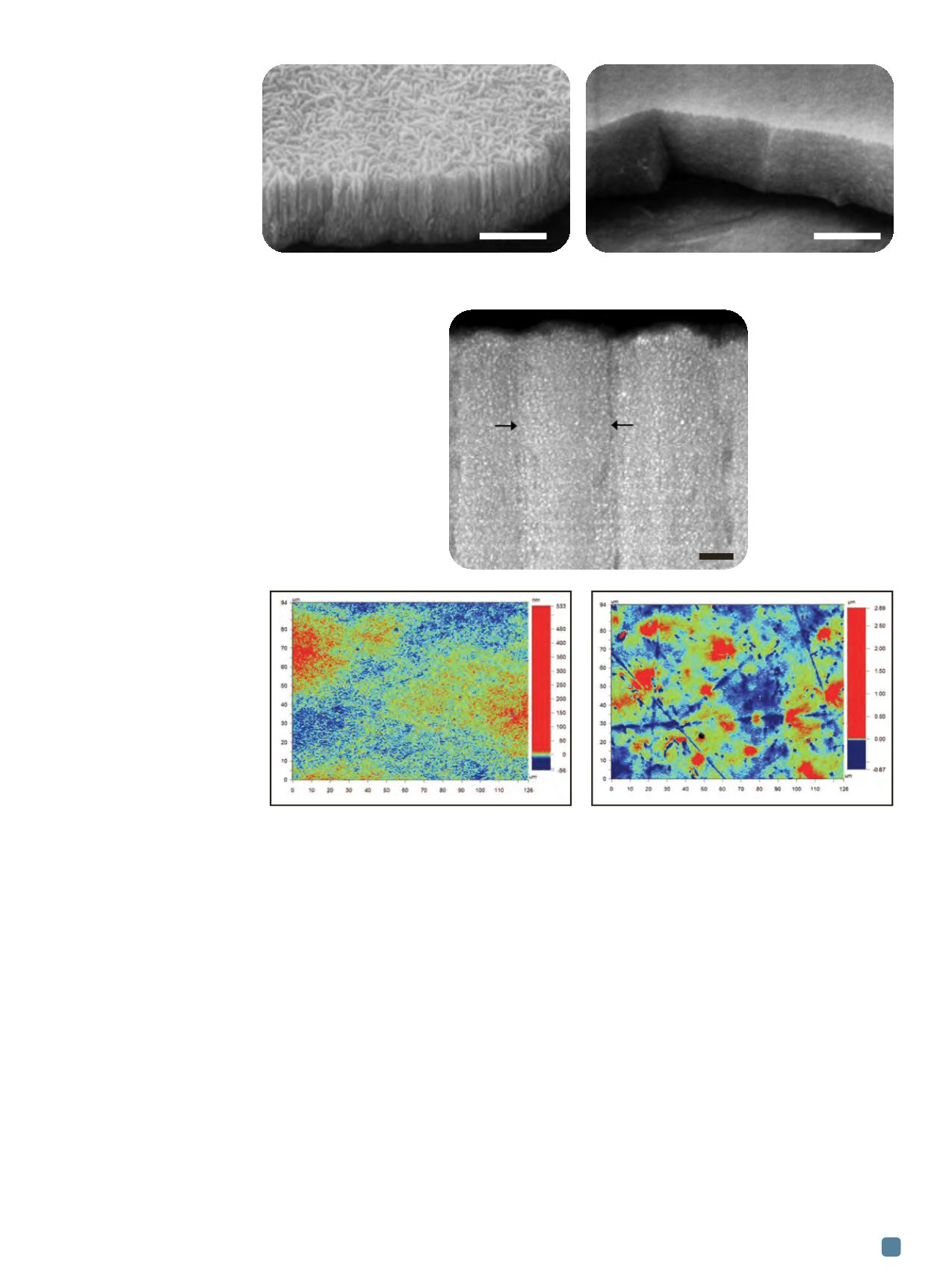

Figure 2 shows the morphology of MoS

2

films at frac-

tured edges created intentionally by plastically deforming

the substrate through indentation with a hardened steel

ball. The columnar morphology of the pure MoS

2

film is

contrasted with the smooth fracture morphology of the

MoS

2

/Sb

2

O

3

film. Doping of MoS

2

films interrupts the

columnar growth of pure MoS

2

, and tends to create films

with more equiaxed grains, and hence reduced porosity.

Figure 3 shows a cross-sectional HAADF-STEM image

of the MoS

2

/Sb

2

O

3

/Au film. This film is a composite with

nanoscale Au particles distributed throughout the amor-

phous MoS

2

/Sb

2

O

3

matrix. Surface roughness changes ac-

companying exposure of MoS

2

/Sb

2

O

3

/Au films to LEO

during the MISSE-7 mission are illustrated in Fig. 4. RMS

roughness increased significantly from as-deposited films

changing from 8.0±0.3 to 34.0±7.9 nm after LEO exposure.

This increase in roughness is likely due to the effects of

heterogeneous erosion of the film by AO, as well as poten-

tial impacts of micrometeoroids or other space debris.

Typical friction coefficient behavior for MoS

2

films is

shown in Fig. 5(a). Friction traces for the MoS

2

/Sb

2

O

3

/Au

films show that sliding begins with a friction coefficient

that is elevated with respect to the steady-state value es-

tablished after several cycles of sliding contact. This initial

friction coefficient is attributed to various chemical and

ADVANCED MATERIALS & PROCESSES •

MAY 2014

33

Fig. 2 —

Fracture surface morphology of pure MoS

2

exhibits a columnar growth morphology (a), and dense

MoS

2

/Sb

2

O

3

films (b) exposed to LEO on EOIM-3.

(a) (b)

Fig. 3

—

Cross-sectional

HAADF-STEM image

of the MoS

2

/Sb

2

O

3

/Au

film. Brighter Au

nanoparticles are

distributed throughout

the film. Arrows show

intercolumnar

boundary.

Fig. 4 —

Contour maps from optical interference profilometry of the MoS

2

/Sb

2

O

3

/Au film in as-deposited

condition (left) with RMS roughness of 8.0±0.3 nm and after exposure to LEO during MISSE-7 (right) with

RMS roughness of 34.0±7.9 nm.

1 µm

1 µm

25 nm