ADVANCED MATERIALS & PROCESSES •

MAY 2014

30

should be explored. It is well documented that minor addi-

tions of reactive elements cause a drastic improvement in

the high-temperature oxidation resistance of these alloys

[4]

.

Because the effectiveness of reactive elements depends on

base alloy chemistry, it is likely that some alloys may con-

tain substantial amounts of reactive elements, but only a

fraction of it is effective in inhibiting oxidation, ignition,

or other forms of surface reactivity. It is reported that a

combination of two or more reactive elements causes a

synergistic effect, substantially increasing their effective-

ness in suppressing ignition. For binary Mg-Y alloys, a sub-

stantial increase in ignition temperature to 900

o

C was

achieved for Y concentrations exceeding 10%

[5]

. That

amount of Y was reduced significantly with Ce additions to

form a Mg-Y-Ce system, which was attributed to a higher

contribution of Y

2

O

3

oxide within the scale. Combining Ca

with Y, and Ag or Be with rare earths, also yields benefits.

Developing nonflammable alloys

The need for nonflammable magnesium alloys, sup-

ported by application opportunities in aerospace, fuels

activities aimed at developing next-generation alloys.

Present commercial grades with improved ignition resist-

ance, such as WE43, ZE41, ZE10, or Elektron 21, were

primarily designed to retain certain mechanical proper-

ties at elevated temperatures. Because they contain rare

earths, ignition and flammability resist-

ance is improved.

A new Mg alloy development direction

contains—in addition to α-Mg—a novel

phase with a long period stacking order

(LPSO) structure

[6]

. The LPSO structure is

formed in the Mg-M-RE system where

M

is represented by Co, Ni, Cu, Zn, or Al, and

RE

are rare earths limited to Y, Gd, Tb, Dy,

Ho, Er, or Tm. The alloy with chemistry of

Mg96.75Zn0.75Al0.5, produced by powder

metallurgy and rapid solidification, reached

an ignition temperature of 780°-940

o

C. As

further progress, Kumadai nonflammable

magnesium alloys were developed, which

consist of C36 type intermetallic com-

pounds, produced by extrusion with a yield

point of 410-460 MPa and an ignition temperature ex-

ceeding 1107

o

C, the boiling point of pure magnesium.

Vital role of surface oxide

Magnesium alloys are not used in typical high-tem-

perature applications and are mostly exposed to high

temperatures during primary melting and at different

stages of the component manufacturing cycle such as

casting, hot forming, or welding

[7]

. The essence of magne-

sium ignition prevention in these processes is to create a

protective barrier layer on the solid or liquid surface, thus

supressing reaction with oxygen. Because conventional

magnesium alloys do not generate protective oxides, they

require protective atmospheres that react with the molten

alloy to form such a barrier.

The phenomena of ignition and flammability are in-

herently related to high-temperature oxidation. In a sense,

onset of ignition is understood as a failure of the protective

oxidation, when surface oxide or other compounds lose

their protective properties. The competing effect of tem-

perature and time during testing of ignition and flammabil-

ity indicates that both phenomena are controlled by the

progress in oxide growth during high-temperature expo-

sures, but before reaching the growth stage when oxide

loses its protective properties due to its morphological

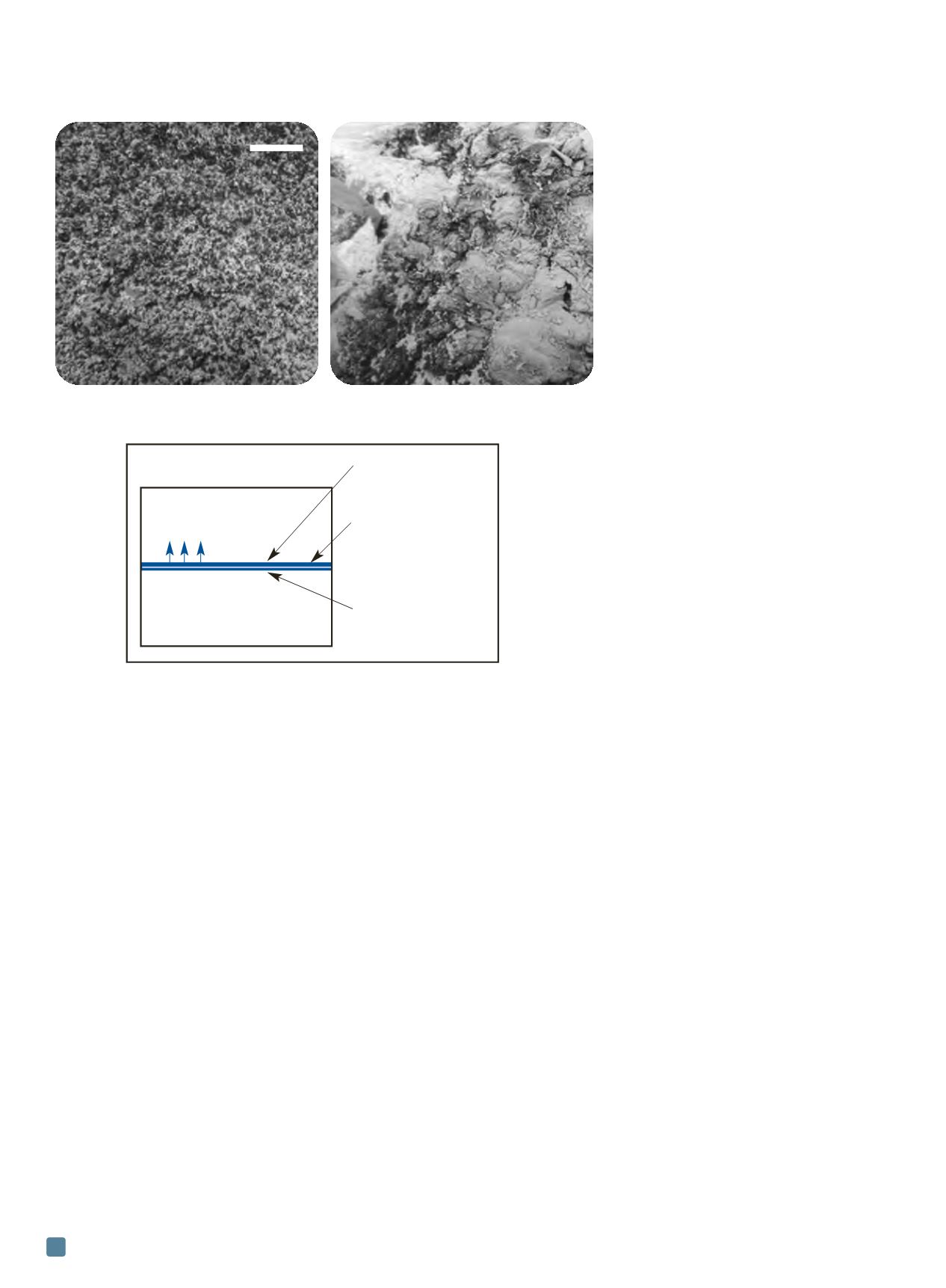

characteristics. As shown in Fig. 3, the morphology of

oxide nodules does not act as a barrier layer, resulting in

magnesium ignition and combustion.

Ignition temperature is not generally correlated with a

presence of the liquid fraction. Although ignition of pure

magnesium may take place in solid state, for the majority

of alloys, it occurs in liquid state. Especially for magnesium

alloys containing reactive elements, the ignition tempera-

ture may be well above the liquidus line. A concern of aero-

space applications is that during in-flight or post-crash fire

scenarios, an aircraft component may experience partial

or complete melting. Because the surface oxide, composed

of pure MgO, does not offer sufficient protection, current

research focuses on modifying its chemistry and mi-

crostructure to suppress oxide diffusivity characteristics

[8]

.

By modifying substrate composition, the integrity and

10 mm

Fig. 3 —

Morphological development during magnesium oxidation and combustion:

(a) MgO oxide nodules formed on Mg-6%Al alloy prior to ignition, and (b) morphology of

combustion product.

(a)

(b)

Fig. 4 —

Schematics explaining suppression of magnesium

ignition and flammability through base alloying and protective

atmospheres of a reactive nature.

Solid protective film

or scale

Reactive gas atmosphere

to form protective

compounds

Base alloying to form

protective oxide (surface

alloying for solid-state

reactions)

Gaseous environment

Solid or liquid Mg alloy