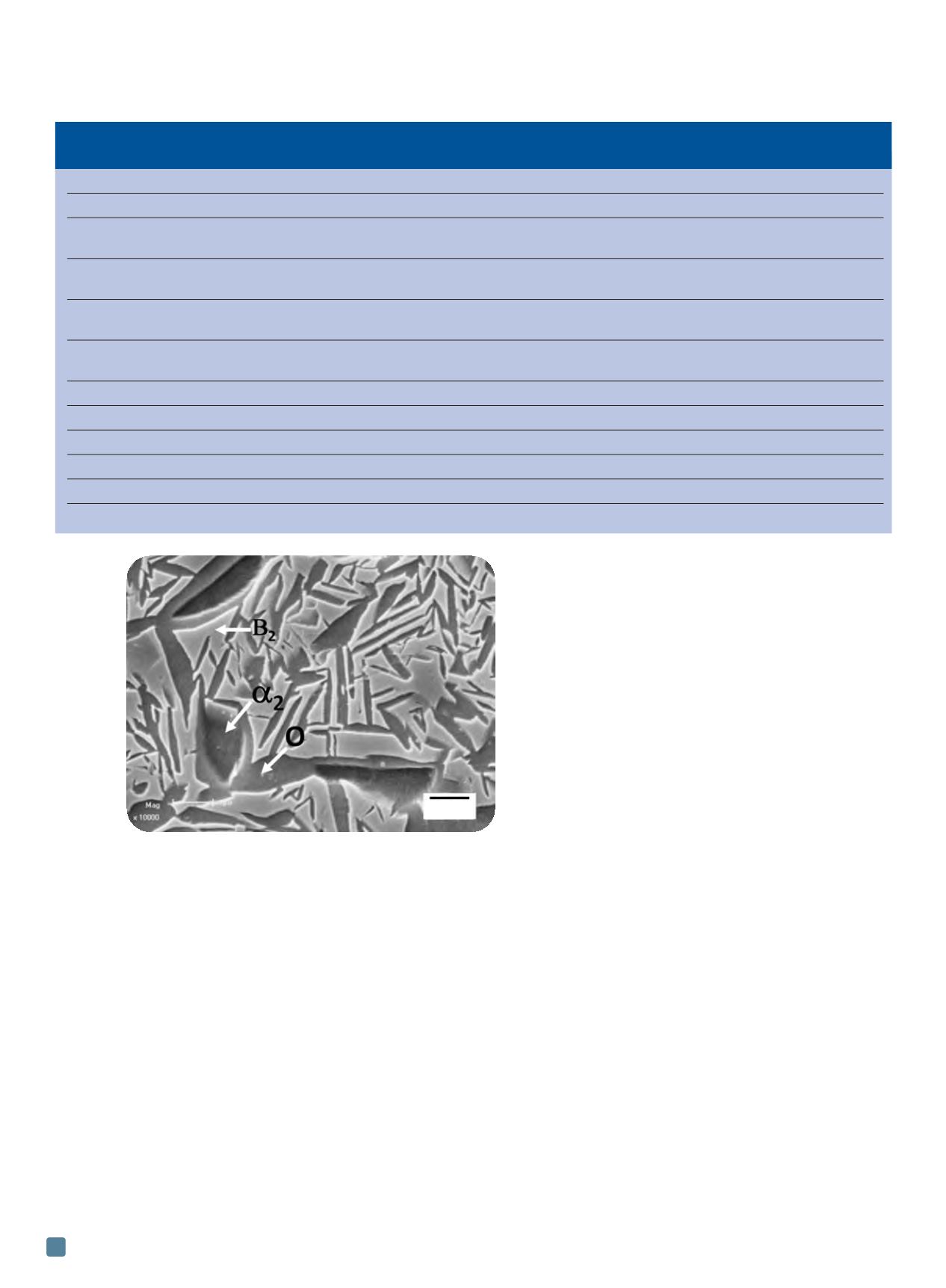

morphology. However, much more complex microstruc-

tures can be generated in these alloys. Depending on the Nb

content and thermo-mechanical processing condition,

Ti

2

AlNb alloys exhibit different combinations of α

2

, O, and

B2 phases. The B2 phase can be retained on quenching and

subsequently decompose to α

2

and O laths via aging. The α

2

phase can also transform to O phase under certain condi-

tions. A detailed study of the microstructure evolution of

several Ti

2

AlNb alloys can be found in Ref. 6. Figure 3 shows

the microstructure of the Ti-22Al-24Nb base alloy with 0.5%

addition of Mo. The dark, gray, and bright regions

correspond to the α

2

, O, and B2 phases.

In the literature, Gogia summarizes the correlation be-

tween microstructure and mechanical properties of the

ternary Ti

2

AlNb alloy system

[7]

. First, in equiaxed α

2

+B2

or O+B2 microstructure, a higher volume fraction of the

B2 phase results in an increase of strength, ductility, and

fracture toughness. The B2 phase can decompose into α

2

and O by aging, with the higher aging temperature causing

a decrease in strength and increase in ductility. For the B2

phase, higher Al content and larger grain size leads to in-

creased ductility and toughness. Secondly, increasing the

cooling rate in the beta heat-treated microstructure pro-

duces a finer microstructure and hence a higher strength,

which is similar to conventional α/β Ti alloys. Lath

microstructure of the α

2

+O phase is preferred in creep-

driven applications. Quaternary additions such as Mo, V,

Si, Fe, and Zr were also explored. The effect of alloying el-

ements on microstructure and mechanical properties is

summarized in Table 1

[8-17]

.

There is no universal alloy composition suitable for all

applications. Rather, alloy composition must be tailored to-

gether with processing to achieve the required properties

for specific components.

Processing and applications

Wrought Processing:

For relatively low-ductility mate-

rials such as Ti

2

AlNb alloys, wrought processing is partic-

ularly useful to achieve the full potential of materials due to

the need to optimize mechanical properties through mi-

crostructure manipulation. Standard processing practices

such as melting, forging, and hot rolling can be used for

making Ti

2

AlNb products. The effect of alternative pro-

cessing methods such as extrusion and isothermal forging

are also under investigation.

Properties of Ti-base intermetallics are more composi-

tion-sensitive than conventional Ti alloys. Ti

2

AlNb alloys

require additional precautions during processing because

their alloying elements have large differences in melting

points and densities (Ti: 1668

o

C, 4.5 g/cm

3

; Al: 660

o

C, 2.7

g/cm

3

; Nb: 2468

o

C, 8.6 g/cm

3

). Ti

2

AlNb ingot material usu-

ally suffers from pronounced segregation of alloying ele-

ments, shrinkage porosity, coarse microstructures, and

ADVANCED MATERIALS & PROCESSES •

MAY 2014

24

TABLE 1 — EFFECT OF ALLOYING ELEMENTS ON MECHANICAL PROPERTIES

OF Ti

2

AlNb ALLOYS

Element

Type

Effect on Mechanical Property

Reference

Al

a

stabilizer

Oxidation and creep resistance improve, ductility and toughness decrease

10

Nb

b

stabilizer

Density, high temperature strength, elevated temperature oxidation resistance,

10

and room temperature toughness increase

Mo

b

stabilizer

Density, tensile strength, elevated temperature creep resistance, and

11, 12

toughness increase

V

b

stabilizer

Density decreases and room temperature ductility, toughness, elevated

9

temperature strength, and creep properties increase

Zr

—

Creep strength improves, yield stress and room temperature ductility are

17

not effected

Si

b

stabilizer

Creep property and oxidation resistance improve

8

Fe

b

stabilizer

Yield strength, ultimate tensile strength, creep resistance improve

13

W

—

High temperature strength and creep resistance improve

9

Ta

b

stabilizer

Yield strength and B2/

b

transus temperature improve

14

Y

—

Hardness improves

15

B

—

Room temperature ductility, hardness, elevated temperature creep property improve 16

Fig. 3 —

Microstructure of a Ti-22Al-24Nb-0.5Mo alloy

showing

a

2

, O, and B2 phases.

1 µm