edfas.org

ELECTRONIC DEVICE FAILURE ANALYSIS | VOLUME 19 NO. 2

4

EDFAAO (2017) 2:4-9

1537-0755/$19.00 ©ASM International

®

FAILURE ANALYSIS ON SOLDERED BALL GRID ARRAYS:

PART II

Gert Vogel, Siemens AG, Digital Factory Division, Control Products, DF CP QM SQA 5

gert.vogel@siemens.comINTRODUCTION

In the February 2017 issueof

EDFA

magazine, the failure

analyis of soldered ball grid arrays (BGAs) with plane

parallel removal of the BGA was discussed. In this second

part, the analysis of voids in the BGA balls is continued,

including case studies with plane parallel polishing of a

printed circuit board assembly (PCBA).

TYPICAL ERROR PATTERN: LARGE

VOIDS IN THE SOLDERED BGA BALLS

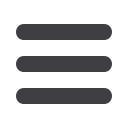

Large voids in BGA solder joints covering more than

30% of the ball area in the x-ray image (Fig. 1) are con-

sidered to be failures, in accordance with IPC-A-610,

“Acceptability of Electronic Assemblies,” and they result

in the PCBA being rejected.

If the failure analysis shows indisputably that the

failure was caused by a misalignment of the first inner

layer, then it is possible tomakea claimagainst theprinted

cirucit board (PCB) supplier. In our example, a metallo-

graphic cross section (Fig. 2, 3) was used to demonstrate

this misalignment.

It is not always possible to clearly identify the root

cause, as in the above example. A cross section frequently

shows only the voids but provides no evidence of the

specific cause.

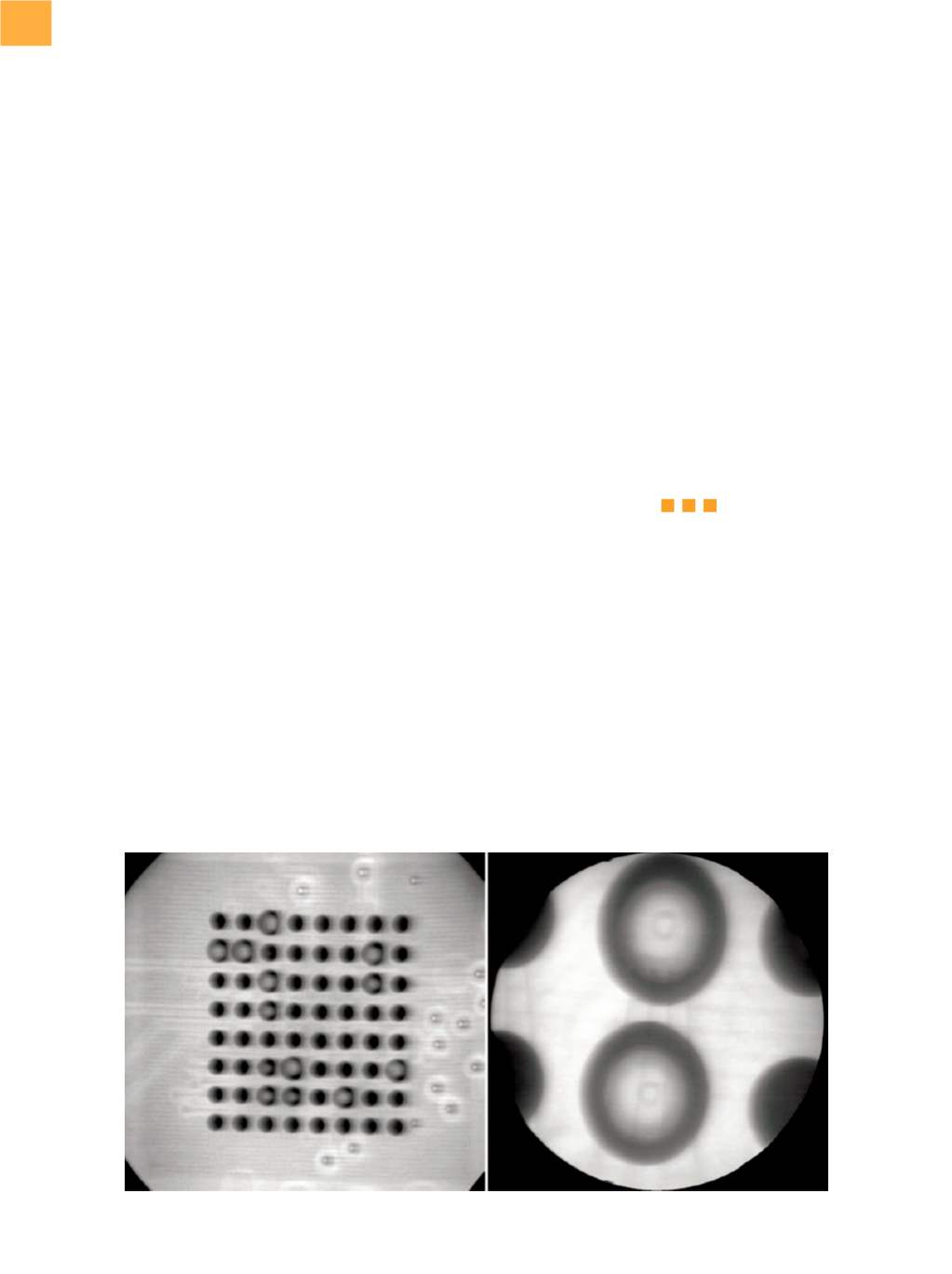

Sometimes, the previously mentioned preparation

by polishing down the BGA allows the root cause to be

determined, as shown in the next case study. Here, two

eye-catching voids were seen during x-ray inspection (Fig.

4). For analysis, the specimen was first ground down to

the center of the voids. This subsequently provided a cross

section in the vertical axis for further analysis. Surprisingly,

not only was a sharp-edged organic particle found in the

“BASED ON MANY CASE STUDIES, IT WAS

SHOWN THAT FAILURE ANALYSIS ON

SOLDERED BGAs ENCOMPASSES A WIDE

FIELD. FAILURES CAN ORIGINATE IN MANY

MANUFACTURING PROCESS STEPS.”

Fig. 1

X-ray of a BGA with many large voids. The microvias can be seen at the center of the voids.