edfas.org

5

ELECTRONIC DEVICE FAILURE ANALYSIS | VOLUME 19 NO. 1

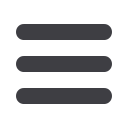

cause can only be revealed by thoroughly controlling all

of the parameters of the soldering process. Another clue

is the optical appearance of the solder balls after a second

reflow process, which is manifested by a creased skin of

tin oxide (Fig. 2).

With several special preparation techniques, many dif-

ferent sources of voiding can be clarified. The goal of the

analysis is always to clarify the root cause of the failure so

that it can be eliminated in the future. If the root cause has

been clearly identified, then an additional benefit is that

it may be possible to make a claim against the supplier.

ELECTRICAL FAILURES WITH EYE-

CATCHING X-RAY OBSERVATIONS

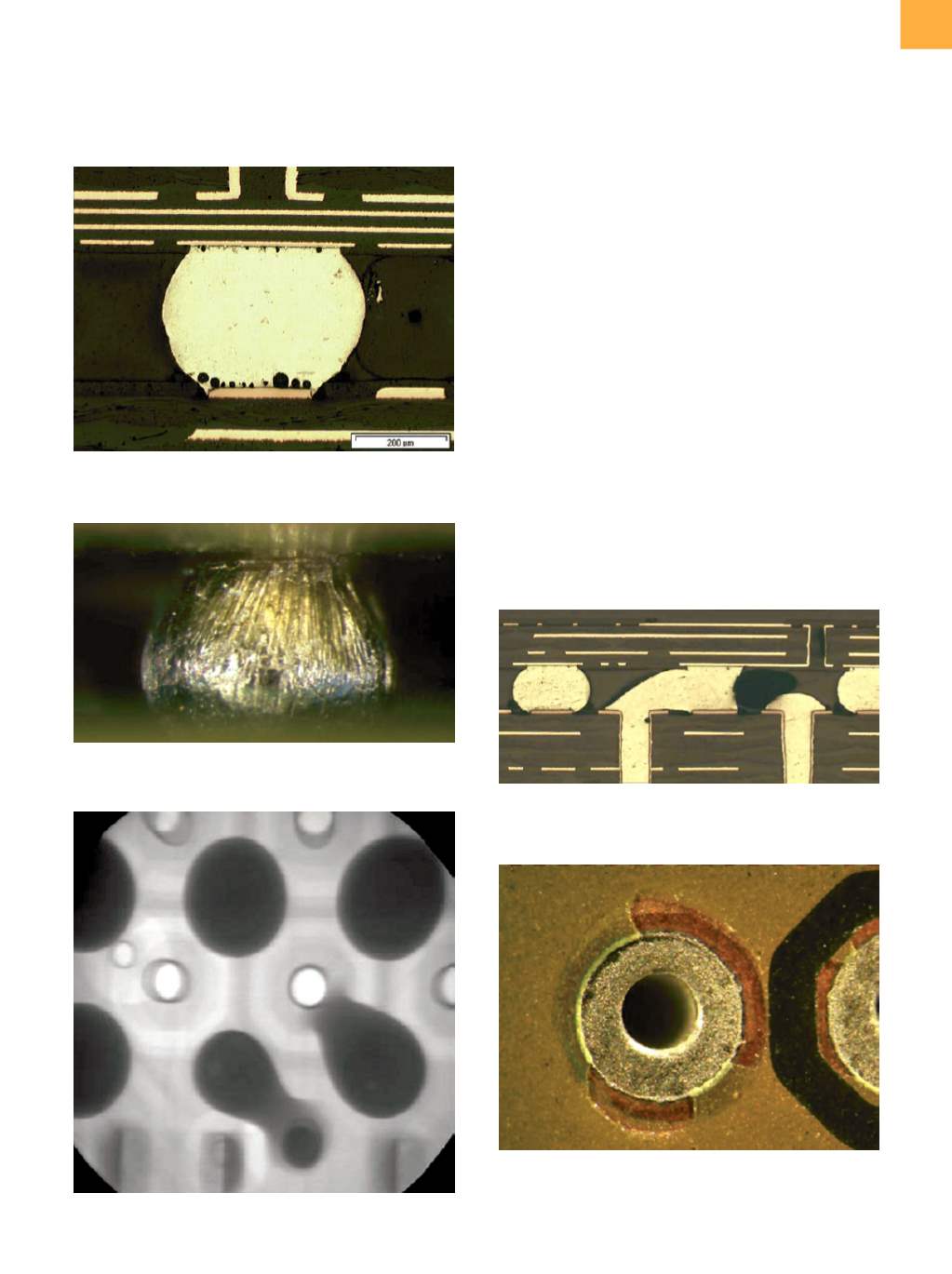

Even if electrical shorts are easily detectedby perform-

ing an x-ray analysis, the determination of the root cause

can still be very complicated. The following example

shows very clearly the short circuit between BGA balls

and adjacent through-holes in the x-ray image (Fig. 3)

as well as in the cross section (Fig. 4); however the root

cause must be searched for in the PCB. A bad immersion

tin rework underetched the solder resist aroundopenings.

It became brittle and flaked off, exposing bare copper that

facilitated the flowof liquid solder across the clearance to

the adjacent contacts (Fig. 5).

Fig. 1

Cross section through a BGA ball with so-called

“champagne voids”

Fig. 2

BGA balls with champagne voids manifest a creased

skin after a second reflow.

Fig. 3

X-ray image of solder faults at BGA balls

Fig. 4

Cross section of the solder faults from Fig. 3. Short

circuits causedbyflowing solder as a result ofmissing

solder resist

Fig. 5

Microscopic inspection of the surface of the PCB

reveals faulty solder resist. Underetched films broke

off, caused by a bad immersion tin rework.