edfas.org

5

ELECTRONIC DEVICE FAILURE ANALYSIS | VOLUME 18 NO. 3

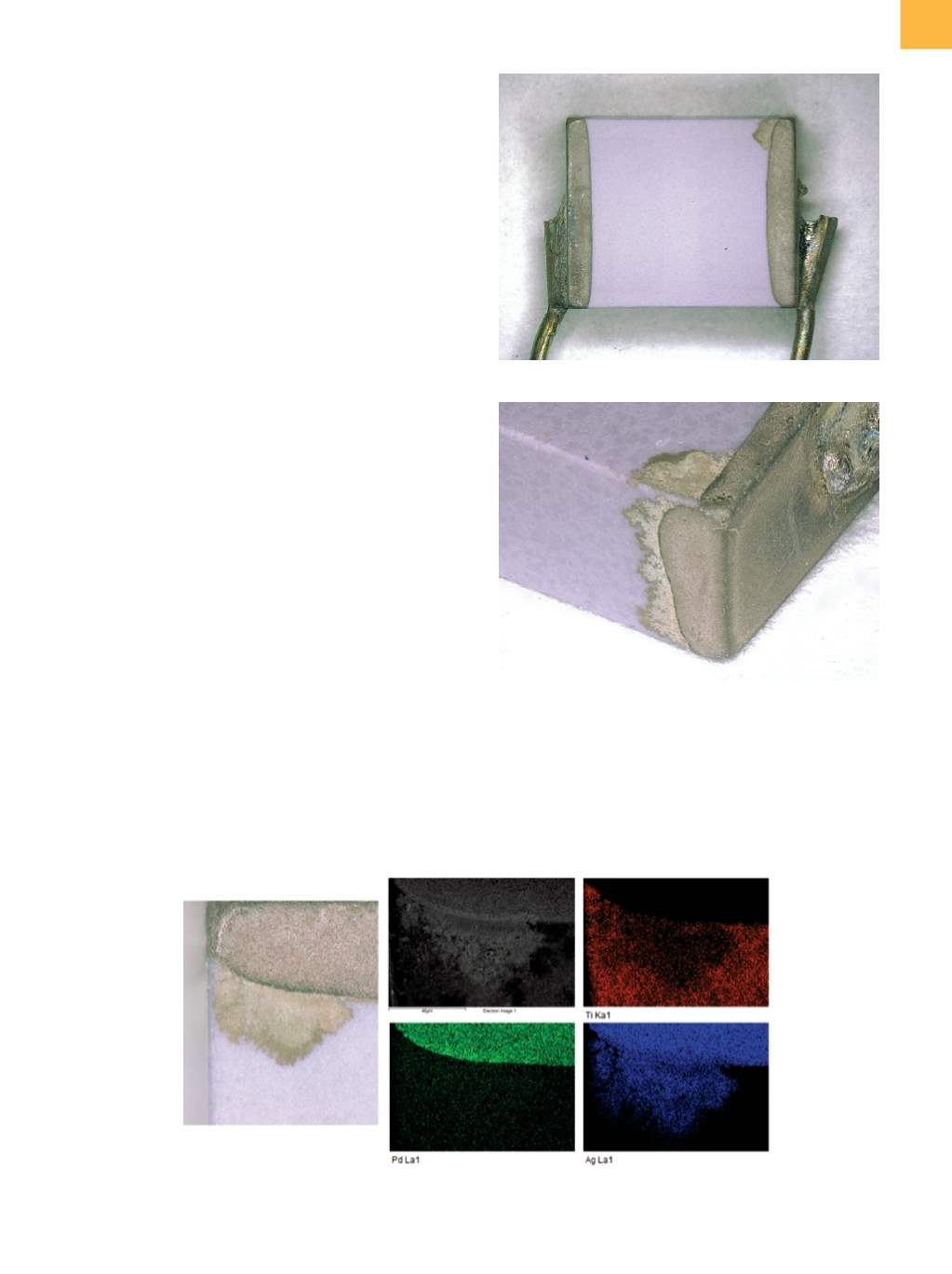

determine the nature of the dendritic growth, energy-

dispersive spectroscopy (EDS) was performed. By creating

the series of element maps shown in Fig. 2, it was deter-

mined that silver had migrated onto the capacitor face.

The other principal component of the termination mate-

rial, palladium, had remained completely in place. As

foreshadowing, note that the internal capacitor plates

also contain silver.

While the capacitor was in the scanning electron

microscope (SEM) chamber, elemental quantification

data were also gathered on the solder to verify that it had

the intended composition. Because components in the

oil-drilling industry are pushed into very extreme operat-

ing environments, a restriction of hazardous substances

exception allows these boards to use leaded solder. A

rectangular-area EDS spectrum acquired over the discol-

oredareawhere the lead joins the cap termination showed

75/23 lead/tin, with the balance being silver. This is a

close-enough match to the expected composition to rule

out the possibility that the solder joint had been contami-

natedwith a low-temperature solder duringmanufacture.

Because component andPCBmanufacturerswho provide

high-temperature assembly always offer low-temperature

products as well, the possibility of inadvertently mixed

solder alloys is a constant threat to reliability thatmust be

guarded against. Consulting the tin-lead phase diagram,

the liquidous point of 75% lead solder is just above

500 °F, soour termination certainly experienced some heat

in order to discolor and partially reflow.

NONDESTRUCTIVE INTERNAL

ANALYSIS

Before going further, it is necessary to understand a bit

more about the constructionof this particular component.

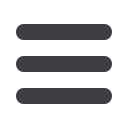

Fig. 1

(a) Optical image showing overall view of the failed

capacitor. Note dendrite growth at upper right and

the reflowed termination solder with heat-stress

discoloration on the right side. (b) Closeup of

dendritic growth from termination onto the cap face

(a)

(b)

Fig. 2

EDS mapping of the dendrite growth. Starting at top-middle image and going clockwise: SEM grayscale image, red

titaniummap, blue silver map, green palladiummap, and color optical image