A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A Y / J U N E 2 0 1 7

5 8

8

TABLE 2 — REDUCTION IN RING TEMPERATURE FOR

NEW AND CURRENT HOT ZONE DESIGNS

Insulation type

Hold temperature, °F

1750 2000 2250

Standard - foil/4 layers

0.5-in. rayon felt/ring

456

544

616

New 2-in. HEFVAC

board/foil face

334

367

405

Temperature

di¯erence

122

177

211

The hold temperature is the outer temperature of the stain-

less steel ring that supports the internal insulation with the

ring radiating to the furnace cold wall, which represents the

radiation losses.

NEW BOARD HOT ZONE DESIGN

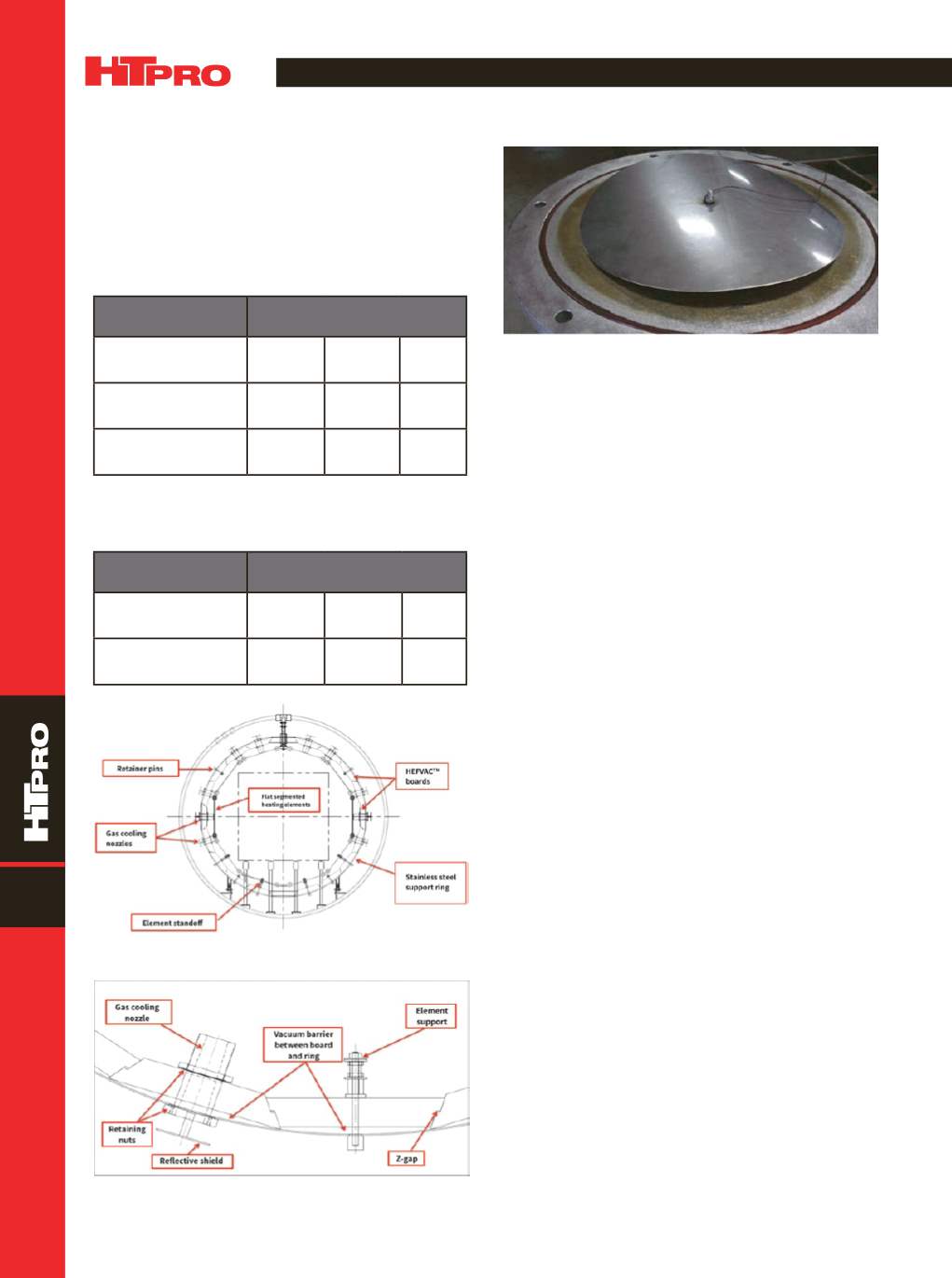

The new hot zone design is shown in Figs. 5 and 6. It

features HEFVAC boards connected in a segmented design

to form a polygon within the support ring with the boards

abutting each other to provide a strong rigid support base.

Gas cooling nozzles, graphite, and heating element supports

hold the felt in place, replacing many types of retaining pins

used in previous designs. This limits the number of retaining

pins required and thus reduces conductive losses through

the pins.

The flat boards only make direct contact with the sup-

port ring along the edge, creating a vacuum barrier between

the board and support ring, further improving thermal loss-

es. In addition, each board has a Z-shaped notch manufac-

tured on both edges for easy installation. This shape also

allows for thermal growth between boards during the heat-

ing cycle and closes any gaps, which further reduces direct

radiation loss from the interior of the hot zone to the support

ring.

The graphite heating elements are flat, segmented

graphite sections of equal dimensions. The heating elements

connect via a graphite splice joint that features a threaded

graphite bolt and nut, providing a quick and simple configu-

ration for replacement.

BOARD-TO-RING GAP THERMAL IMPROVEMENT

Table 3 shows an example of the new HEFVAC board’s

projected temperature improvement with a flat plate versus

a curved plate (Fig. 7), representing the shape of the support

ring (thermocouple at center of both plates). This gap further

improves the thermal loss by approximately 10%. The new

HEFVAC design is expected to reduce overall power losses

when holding at elevated temperatures by 30-40%.

~HTPro

For more information:

Real Fradette is senior techni-

cal consultant, Solar Manufacturing Inc., 1983 Clear-

view Rd., Souderton, PA 18964, 267.384.5040 ext. 1560,

real@solaratm.com,

www.solaratm.com.TABLE 3 — BOARD-TO-RING GAP TEMPERATURE

IMPROVEMENT WITH FLAT VERSUS CURVED PLATE

Insulation type

Hold temperature, °F

1750 2000 2250

2-in. HEFVAC board

with flat plate

334

367

405

2-in. HEFVAC board

with curved plate

309

332

365

Fig. 5 —

Schematic of new furnace design using HEFVAC board.

Fig. 6 —

Schematic of HEFVAC board cross sections showing

Z-shaped design.

Fig. 7 —

Board/ring vacuum gap test.

FEATURE