A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

M A Y / J U N E

2 0 1 7

5 7

7

face area,

T

is the radiating surface temperature (K) of the

support ring, and

T

c

is the temperature (K) of the surround-

ing surface chamber wall. The Stefan-Boltzmann law also

applies to power losses at radiating surfaces. The equation

shows that energy loss is proportional to the fourth power of

the ring temperature (walls “A” and “B” in Fig. 3). Reducing

the temperature of wall “A” is a key factor in improving ener-

gy efficiency in the vacuum furnace.

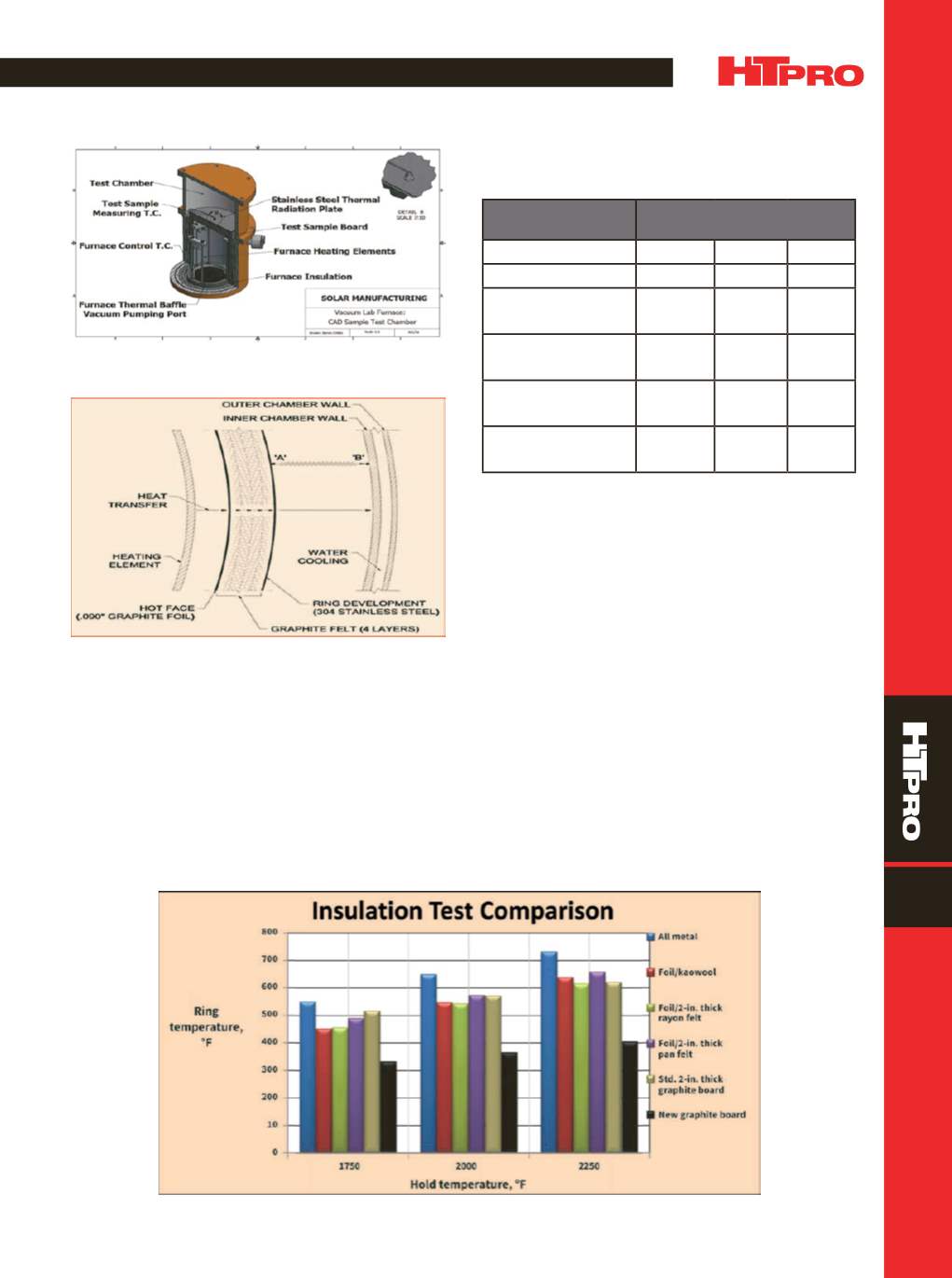

Table 1 shows prior insulation test results and results

using the new board (last row in table). Figure 4 shows the

improvement in thermal efficiency for the new graphite

board compared with other modern designs.

CURRENT DESIGN VERSUS NEW DESIGN

Based on improved results from using the new graph-

ite board, Solar named the board HEFVAC for high efficiency

vacuum capabilities and applications, and will introduce a

new hot zone design that incorporates the more energy ef-

ficient insulating board. Until now, the foil/2-in. thick rayon

felt combination offered the best energy efficient graphite

vacuum furnace (Table 1 and Fig. 4). The new design offers

a significant improvement over the current design. The

HEFVAC lowers the ring temperature by nearly 200°F at a

hold temperature of 2250°F. At a hold temperature of 2000°F,

a 61% improvement in temperature loss occurs (Table 2).

Fig. 2 —

Schematic of test chamber showing extension for test

sample placement.

Fig. 3 —

Schematic of furnace wall cross section: Radiation heat

transfer from ring wall “A” to cold wall “B” largely contributes to

heat loss within the furnace hot zone.

TABLE 1 — COMPARISON OF PRIOR INSULATION

TEST RESULTS AND NEW BOARD RESULTS

Insulation type

Hold temperature, °F

1750 2000 2250

All metal (3 Mo, 2 SS)

551

650

733

Foil/2-in. kaowool

452

548

640

Foil/2-in. rayon

graphite felt

456

544

616

Foil/2-in. pan

graphite felt

490

574

659

Standard graphite

board (avg.)

517

572

622

New 2-in. board with

foil facing*

334

367

405

*New graphite board material from Graphite Machining Inc.

6

Fig. 4 —

Comparison of thermal eiciency of furnace insulation package.

FEATURE