A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A Y / J U N E 2 0 1 7

6 2

FEATURE

12

Establish HTC for each specimen location.

Two methods

are used to correlate hardness measurements to HTC. One

method uses results from the standard gas quench using

the Praxair-type unit (Fig. 2). If the same heat of steel is used

to develop the center hardness versus the HTC curve using

the same standard cooling tests as in the furnace quenching

evaluation, then that base curve canbe used to apply anHTC

to each specimen (or each location) for the furnace. Anoth-

er method employs a heat treat simulation package such

as Dante to determine the HTC that produces the measured

hardness value at the center of those specimens.

For a furnace with very slow cooling (HTC values be-

low 200 W/m

2

K), it is difficult to use a common diameter

specimen between the Praxair standard test and a furnace

evaluation. The Praxair test cannot accurately create a slow-

er cooling standard. The furnace evaluation also requires a

high hardenability material and possibly a smaller diameter

to differentiate surface cooling rates in all areas of the fur-

nace. Heat treat simulationmust be usedwhen the standard

Praxair-type test cannot be used.

TEST RESULTS

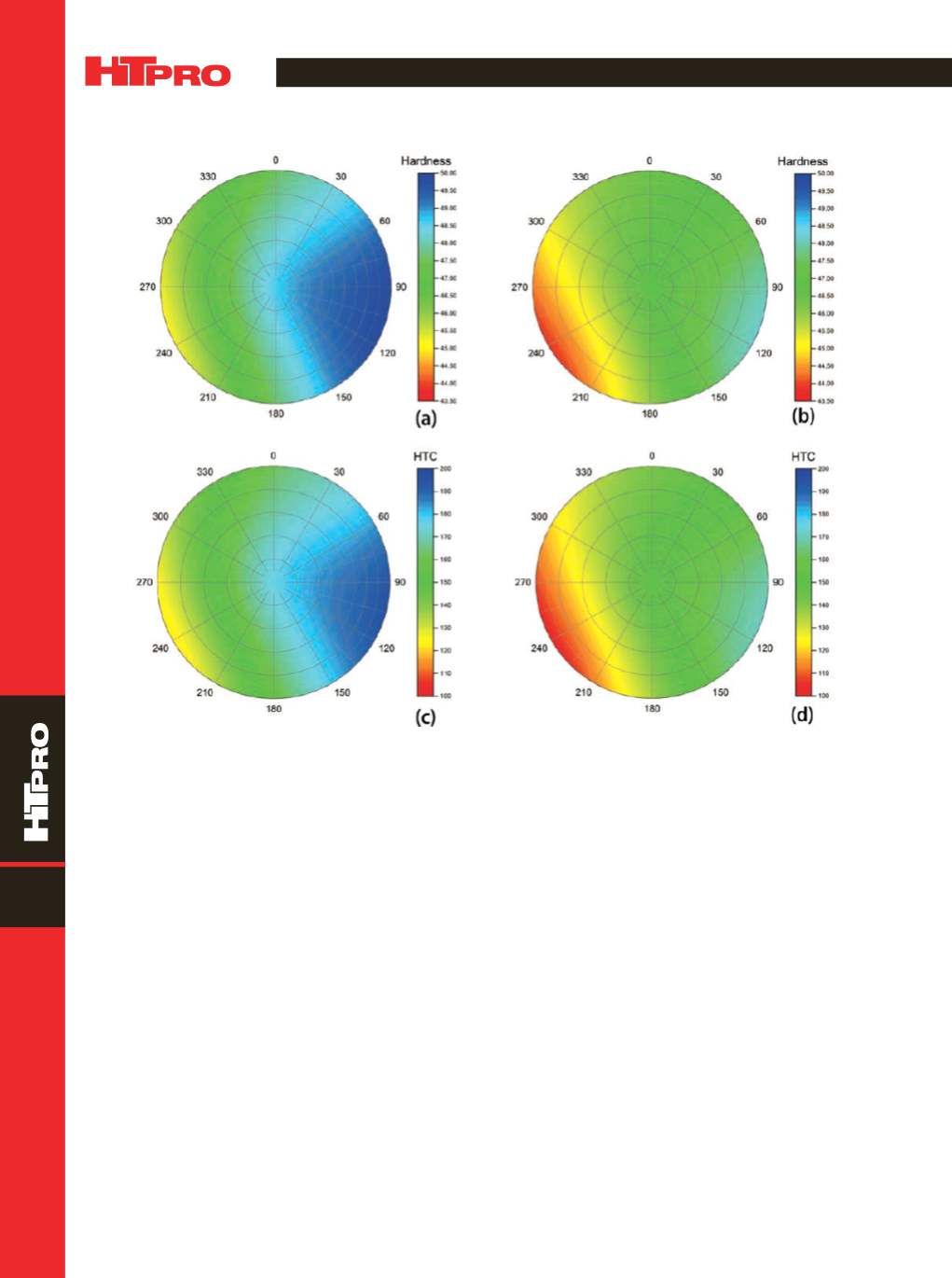

Figure 5 shows results for 13-mm diameter by 100-mm

long (0.5 by 4 in.) AISI 4340 bars tested in a 2-bar nitrogen fur-

nacewith gas flowdirection as shown in Fig. 4. Sampleswere

placed to test primarily the front and rear of the furnace. Core

hardness varies from 44 to 49.5 HRC, which contains 50% to

90% martensite

[1]

. Figures 5(a) and 5(c) show that the front

provides higher gas quench intensity comparedwith the rear

(the strongest quench intensity is at right side of the front).

The weakest quench intensity is at the lower left corner of

the rear as shown in Figs. 5b and 5d. Based on measured

hardness, a Dante simulation was conducted to determine

the surfaceHTC (Figs. 5c and 5d). A 4340 13-mmtest is appro-

priate to quantify quench intensity and uniformity in a 2-bar

nitrogen gas quench furnace.

~HTPro

For more information:

Michael Pershing is senior technical

steward−heat treat, Caterpillar Inc., 100 NE Adams St., Peo-

ria, IL 61629, 309.578.9676,

pershing_michael_a@cat.com,

www.cat.com.

Fig. 5 —

Hardness and HTC of samples placed to test the front and rear of the furnace: (a) hardness of front side, (b) hardness of rear side,

(c) HTC distribution of front side, and (d) HTC distribution of rear side.