A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A Y / J U N E 2 0 1 7

5 6

FEATURE

6

C

urrent vacuum furnace hot zone designs include

all-metal shielding, ceramic fiber (kaowool), and

graphite fiber, foil, and board combinations. Typically,

a stainless steel ring structure supports the insulation pack-

age within the hot zone (Fig. 1). Energy studies shows that

the all-metal hot zone is the least efficient, requiring a larger

and more expensive power supply when operating at tem-

peratures around 1150°C (2100°F). All-metal designs usually

include a combination of thin molybdenum and stainless

steel shields. These hot zones typically offer better vacuum

levels and super clean work compared to other options.

However, they are more expensive, 30% less efficient, and

usually last about half the time of other insulated hot zones.

Ceramic fiber provides superior insulating properties,

but it tends to absorb substantial amounts of water vapor

when opened to air. This leads to longer evacuation times,

especially during high-humidity days. In addition, ceramic fi-

bers shrink at high temperatures and create gaps within the

support ring that result in additional energy losses.

The majority of all-purpose vacuum furnaces manufac-

tured today use a combination of graphite felt and foil and

graphite felt and board. For example, most modern furnaces

contain four 0.5-in. thick layers of graphite felt with either a

graphite foil hot face or a rigid graphite board hot face (pri-

marily used in high-pressure gas quench furnaces). Graph-

ite felt has a tendency to absorb water vapor, but not to the

same extent as ceramic fibers. Care must be taken to keep

the furnace closed as much as possible. With correctly sized

vacuum pumps and proper maintenance and operating

practices, this type of furnace is capable of producing very

clean work.

Recently, Solar Manufacturing and Solar Atmospheres

compared a new graphite board with current products.

The new board (a standalone insulation package produced

by Graphite Machining Inc., Topton, Pa.) is a 2-in. thick,

high-density compressed graphite fiberboard sealed with a

proprietary graphite polymer tominimize porosity andmois-

ture absorption.

COMPARISON OF POWER LOSS

AND INSULATION

To conduct experimental work, a standard vertical

laboratory-type vacuum furnace (12-in. diameter by 18-in.

high) was modified with an extension piece placed on the

main chamber (Fig. 2). The extension provided a space to

add thicker insulation packages to the top of the furnace

hot zone. The temperatures of the furnace hot zone and

outer stainless steel lid were measured using calibrated

Inconel thermocouples at three different stabilized furnace

temperatures.

The temperature of the outer stainless steel lid rep-

resents the temperature of support ring “A” (Fig. 3) adjacent

to the furnace cold wall “B.” The major thermal loss in a vac-

uum furnace stems from the ring radiating energy to the fur-

nace coldwall. Other losses via hearth pins and nozzle direct

radiation losses are not included in the analysis.

Total energy radiated by a black body is given by the

Stefan-Boltzmann law:

P

=

HV

A

(

T

4

–

T

c

4

)

where

P

is net radiated power,

H

is emissivity of the radiating

surface (0.55 for stainless steel),

V

is the Stefan-Boltzmann

constant (5.670367

u

10

−8

W

m

2

K

−4

),

A

is the radiating sur-

NEW DEVELOPMENTS IN VACUUM FURNACE HOT ZONE DESIGN

A novel hot zone design featuring new graphite boards reduces heat loss

and improves overall hot zone power requirements.

Real J. Fradette,* Virginia Osterman,* and William R. Jones, FASM*

Solar Atmospheres Inc., Souderton, Pa.

*Member of ASM International

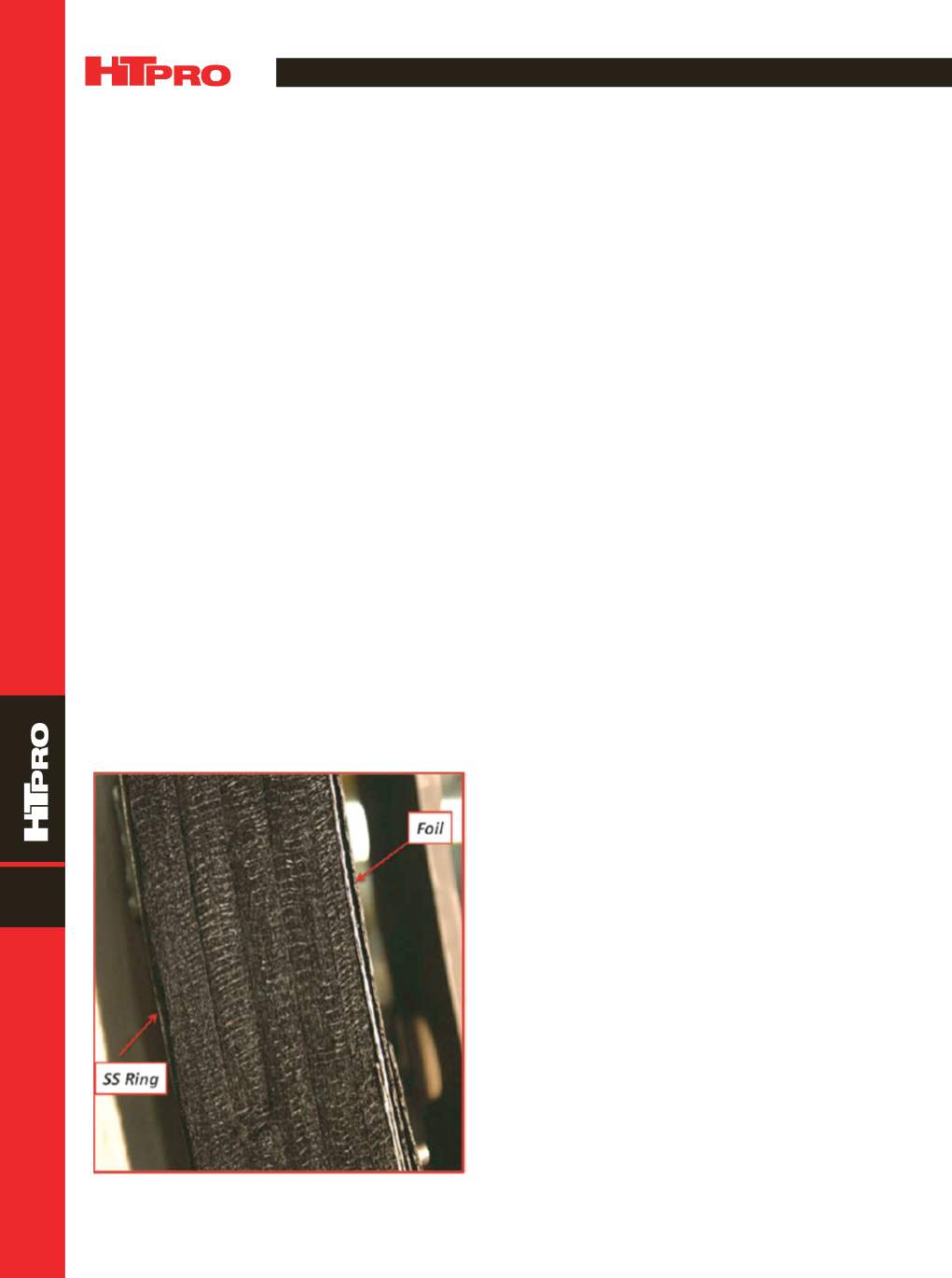

Fig. 1 —

Graphite hot zone in which stainless steel support ring

holds insulation package in place.