A D V A N C E D M A T E R I A L S & P R O C E S S E S | N O V E M B E R / D E C E M B E R 2 0 1 6

1 2

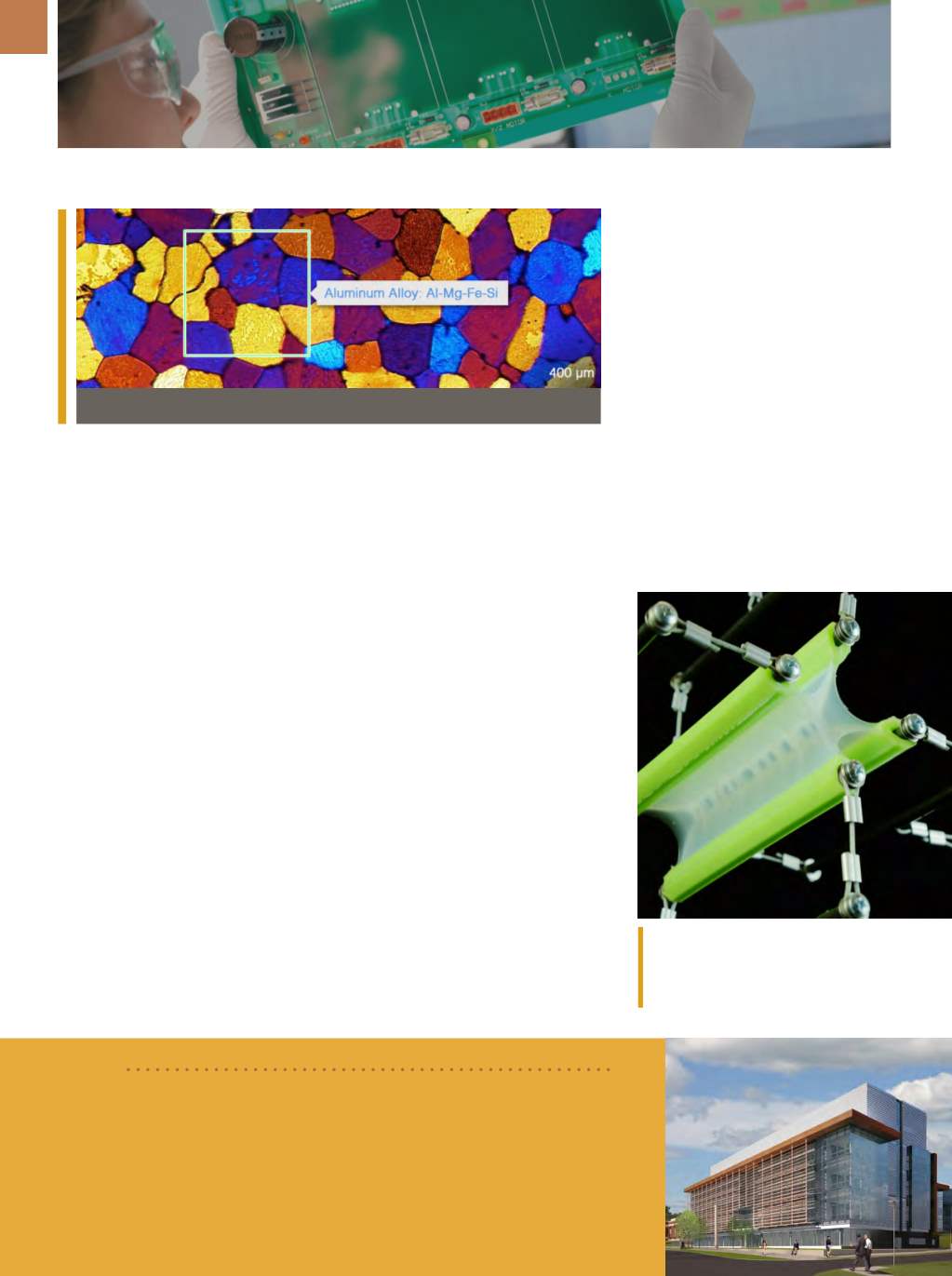

MACHINE LEARNING

LEARNS MATERIALS

In a field that has historically relied

on human experts to identify research

images by hand, a materials science

professor at Carnegie Mellon Univer-

sity, Pittsburgh, developed a system

that uses machine learning algorithms

to search, sort, classify, and identify

visual data sets in materials science.

Professor Elizabeth Holm is using the

algorithms—familiar to Google image

search users—to automatically recog-

nize and categorize images of micro-

structures. Because the algorithms are

designed to improve as they encounter

more data, they are especially suited

to the vast image libraries amassed in

materials science.

Holm’s machine learning system

could find application in research, indus-

try, publishing, and academia. For exam-

ple, it could be used to search scientific

journal archives to determine if a photo

was previously published, or automat-

ically categorize visual data for indus-

tries or research labs. “Big companies

can have archives of more than 600,000

research images,” explains Holm. “No

one wants to look through those, but

they want to use that data to better un-

derstand their products.” The next step

is application in metal 3D printing. Holm

and her team are compiling a database

of experimental and simulated metal

powder micrographs in order to better

understand what types of raw materials

are most appropriate for additive manu-

facturing processes.

cmu.edu.

INSTABILITY PREDICTION

PROVEN AFTER LONG STRETCH

Researchers at the Harvard John

A. Paulson School of Engineering and

Applied Sciences (SEAS), Cambridge,

Mass., demonstrated for the first time

that a decades-old theory proves true:

With the right amount of tensile force, a

thick cube of soft material will sudden-

ly deform into a thin, flat plate. In 1948,

applied mathematician Ronald Rivlin

predicted the behavior, but materials

scientists had been unable to prove the

theory experimentally—until now. The

Google-like algorithms are now being used to categorize micrographs.

Under biaxial tension, the elastomer

sample’s center deforms, breaking the

symmetry and becoming flat. Courtesy

of Harvard SEAS.

BRIEF

Construction is underway on the new Materials Design Laboratory (MDL) at the DOE’s

Argonne National Laboratory,

Lemont, Ill. The facility will complete Argonne’s

Energy Quad, a group of four adjoining buildings designed to maximize collaboration

between energy and materials scientists. Encompassing roughly 115,000 sq. ft. of

laboratory and office space, including 10,000 sq. ft. of lab space for radiological

research, the MDL is on track to receive LEED Gold certification. The lab will house

microstructure research and materials testing under extreme conditions.

anl.gov.

The newMaterials Design Laboratory at Argonne National Laboratory broke ground in September.

Harvard team triggered this instability

in a centimeters-thick elastomer block,

deforming it into a flat surface. To do so,

they stretched a thick, soft elastomer

made of silicon rubber at each corner.

Under biaxial tension, the sample’s cen-

ter deformed, breaking the geometrical

symmetry and becoming suddenly flat.

“This research widens the design

space for newarchitectedmaterials that

use instabilities to change or enhance

their functionality,” says Johannes T.B.

Overvelde, former graduate student at

SEAS. “With this instability, we can cre-

ate materials that can suddenly switch

between behaviors by using simple

triggers to change their geometry.”

harvard.edu.

EMERGING TECHNOLOGY