A D V A N C E D M A T E R I A L S & P R O C E S S E S | O C T O B E R 2 0 1 6

8

METALS | POLYMERS | CERAMICS

energies, you get a sort of frustration

as the material tries to crystalize,” adds

Eric Perim, a postdoctoral researcher at

Duke. “The material can’t decide which

crystalline structure it wants to con-

verge to, and a metallic glass emerges.

What we created is basically a measure

of that confusion.” The team at Duke

developed a database to simulate the

hundreds of crystalline structures each

alloy could potentially take. They cre-

ated a program to analyze the various

structures and compare the energy

required to form them. Alloys that can

form many different structures whose

energy is similar are likely candidates

to form a metallic glass. The teams

at Harvard and Yale then verified the

predictions experimentally. The new

approach is able to predict the forma-

tion of known metallic glasses 73% of

the time and has identified hundreds of

new candidates for metallic glass made

from simple, two-element alloys. Now

that the researchers can predict good

candidates for metallic glass, they can

start looking for new material systems.

seas.harvard.edu.

AUTOMOTIVE ALUMINUM

RECYCLING GOING STRONG

New research from Worcester

Polytechnic Institute’s (WPI) Center

for Resource Recovery and Recycling

confirms an overall recycling rate of

91% for automotive aluminum in the

U.S. The peer-reviewed study, funded

by the Aluminum Association, exam-

ines how much aluminum used in the

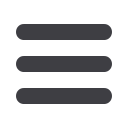

Whenmetal alloys are melted, the atoms lose their ordered structure and become

amorphous, as seen above. Courtesy of the Vlassak Group/Harvard SEAS.

A hydrolysis-resistant, bio-based

polyamide, EcoPaXX, from

Royal

DSM,

the Netherlands, was recent-

ly approved for use by a German

car manufacturer. A thin-walled

T

connector for a coolant hose in

this grade, Akulon PA66, is now

available in two versions: HR-HG6

and HR-HG7, containing 30% and

35% glass fiber reinforcement, re-

spectively. Both comply with OEM

requirements for a high retention

of flexural strength after immer-

sion in the solution for 1000 hours

at 135°C. Targeted applications

include expansion tanks, air intake

manifolds, oil pans with integrated

cooling channels, and oil filter/

cooler modules.

dsm.com.

BRIEFS

Hot rolled or hot forged bars of AUTO-Steel from

Advanced Materials

Development (AMD) Corp.,

Canada, can be used in car and truck car-

burized powertrain and transmission components such as camshafts,

gears, axles, and shafts. Carburized Grade1 features surface hardness of

HRC 61-62 and core hardness of HRC 45-46. Grade2 is a medium carbon,

deep nitriding composition suited for high precision components. After

quenching and tempering, Grade3 features hardness of HRC 58-60 and

UTS of 325-335 ksi.

info@amdoncorp.com.

FINDING ALLOYS TO FORM

BULK METALLIC GLASS

Researchers from the Harvard John

A. Paulson School of Engineering and

Applied Sciences (SEAS), Cambridge,

Mass., in collaboration with colleagues

from Duke and Yale universities, re-

cently developed a method to predict

which alloys might form a bulk metal-

lic glass. “For the first time, we’ve ob-

served a strong correlation between

the glass-forming ability of an alloy and

properties that we can easily calculate

ahead of time,” says Joost J. Vlassak, a

materials engineering professor at SEAS.

When metal alloys are melted, the

atoms lose their ordered structure—al-

though most will snap back to their rigid

crystal structures when cooled. Howev-

er, bulk metallic glasses, if cooled at cer-

tain rates, will retain the random amor-

phous structure even in the solid state.

Yet some alloys havemore options when

it comes to their crystal structures. When

these alloys are being cooled into solids,

their atoms could crystallize in many dif-

ferent ways. “If a particular alloy compo-

sition exhibits many structurally differ-

ent, stable or metastable crystal phases

that have similar formation energies,

these phases will compete against each

other during solidification,” explains

Vlassak. “Essentially, the liquid becomes

so confused, it remains amorphous as it

solidifies.”

“When you get a lot of structures

forming next to one another that are

different but still have similar internal