A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

O C T O B E R

2 0 1 6

1 3

Joseph McKeown uses LLNL’s DTEM to investigate rapid alloy solidification. Courtesy

of Julie Russell/LLNL.

IMAGING ALUMINUM ALLOY

SOLIDIFICATION

Engineers at the University of

Pittsburgh are focusing the power of a

dynamic transmission electron micro-

scope (DTEM) on rapid solidification of

aluminum alloys associated with laser

or electron beam processing technolo-

gies. Unlike a traditional transmission

electron microscope, the DTEM at Law-

rence Livermore National Laboratory

(LLNL), Calif., uses lasers to achieve

high time resolution, allowing research-

ers to see how a chemical reaction,

structural deformation, or phase trans-

formation takes place with an unprece-

dented combination of spatial and tem-

poral resolution—in nanometers and

nanoseconds.

“DTEM allows you to see the in-

terface between the solid and liquid

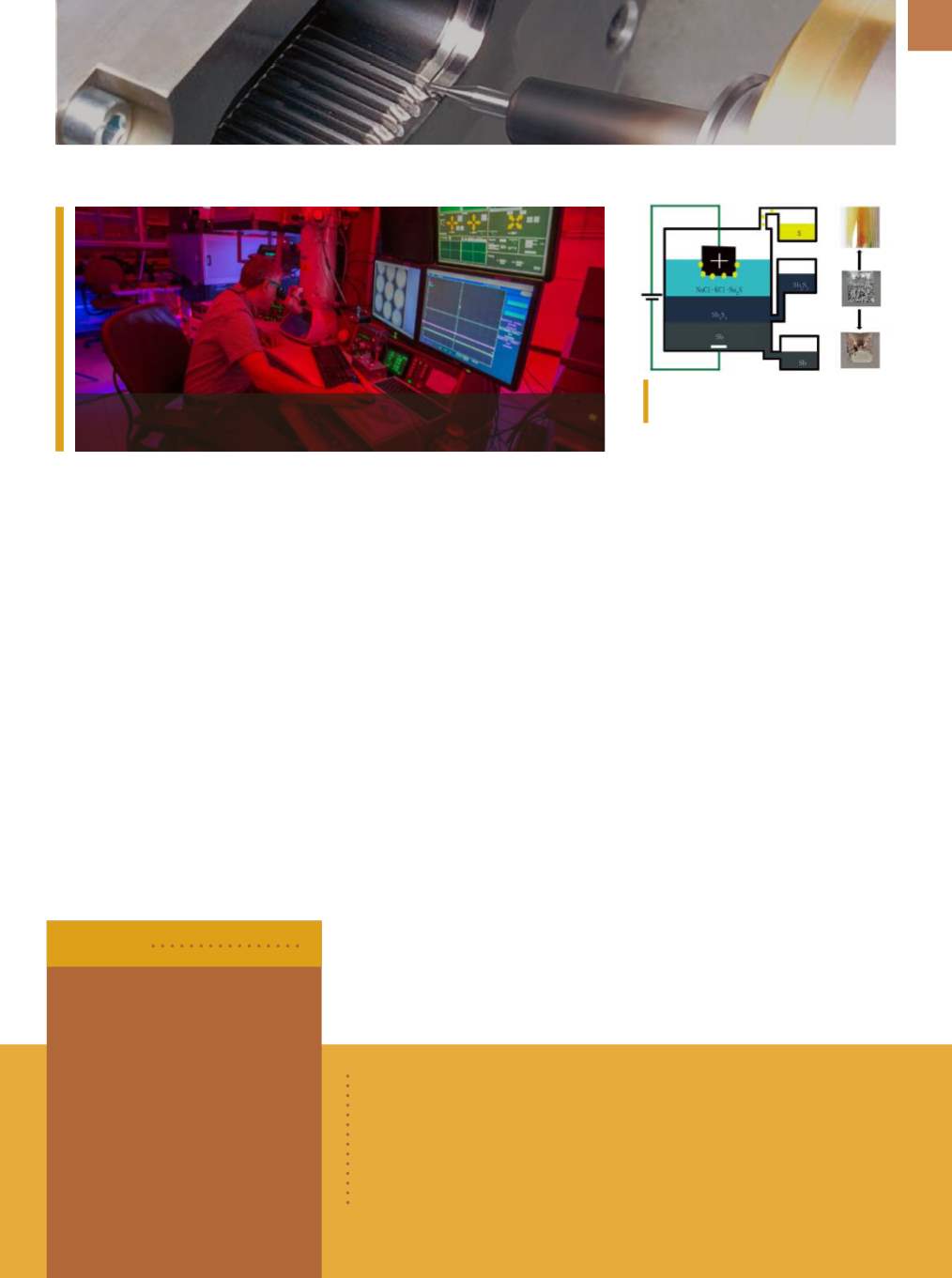

Electrolysis of a molten semiconductor.

Courtesy of the researchers.

during rapid solidification,” says Joe

McKeown, an LLNL materials scientist.

“We can image this process as it’s mov-

ing rapidly, and from that we can mea-

sure just how fast it’s going. There’s no

other technique to do that.” Previously,

these transformations could only be

simulated on a computer. McKeown

said the data collected from the study,

funded by a three-year, $500,000 grant

from the National Science Foundation,

could improve predictive capabili-

ties for metal additive manufacturing

and validate existing computer models.

pitt.edu, llnl.gov.

SURPRISE! BATTERY MAKES

99.9%PURE METAL

While attempting to develop

new electrochemistry for a battery, re-

searchers at Massachusetts Institute of

Technology (MIT), Cambridge, instead

discovered an innovative method for

producing antimony. During experi-

ments with all-liquid, high temperature

storage batteries, composed of layers

of molten metals or salts, researchers

placed a second electrolyte—in this

case, antimony sulfide—between the

positive and negative electrodes. When

they attempted to charge the battery,

liquid antimony was produced instead.

Antimony sulfide is a good conductor

of electrons and normally would not

allow for electrolysis, which demands

an ionic conductor. However, electrol-

ysis was facilitated by adding an ionic

conductor layer on top of the molten

semiconductor.

The process formed a pool of

99.9% pure antimony at the bottom of

the cell, while pure sulfur gas pooled

at the top, where it could be easily col-

lected. In typical smelting processes,

sulfur gas bonds with oxygen in the

air to form sulfur dioxide—the major

cause of acid rain—requiring subse-

quent scrubbing. As a single-step con-

tinuous process, electrolysis is much

more efficient than traditional heat-

based smelting, and if used to produce

other common industrial metals such

as copper, nickel, or steel, could dra-

matically lower metal prices and re-

duce air pollution and greenhouse gas

emissions.

mit.edu.

Kobelco Aluminum Products &

Extrusions Inc.,

Japan, a sub-

sidiary of

Kobe Steel Ltd.,

broke

ground on its production facility

in Bowling Green, Ky., where the

company will manufacture alumi-

num bumper and car frame materi-

al for the U.S. automotive industry.

Fabrication will begin in late 2017,

with melting to extrusion processes

coming online in late 2018.

kobelcocm-global.com.

BRIEFS

The Shagang Group,

China, signed a licensing agreement with

Cas-

trip LLC,

Charlotte, N.C., to use Castrip technology in conjunction with

existing steelmaking furnaces for casting and finishing high strength, thin

gauge sheet, with widths to 1600 mm and gauges from 0.7-1.9 mm. Esti-

mated annual capacity is 500,000 tons per line, and hot commissioning

of the new facility is scheduled for late 2017. The Castrip process will

reduce energy use and emissions in the casting and rolling process.

sha-steel.com/eng, castrip.com.

PROCESS TECHNOLOGY