A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

O C T O B E R

2 0 1 6

1 1

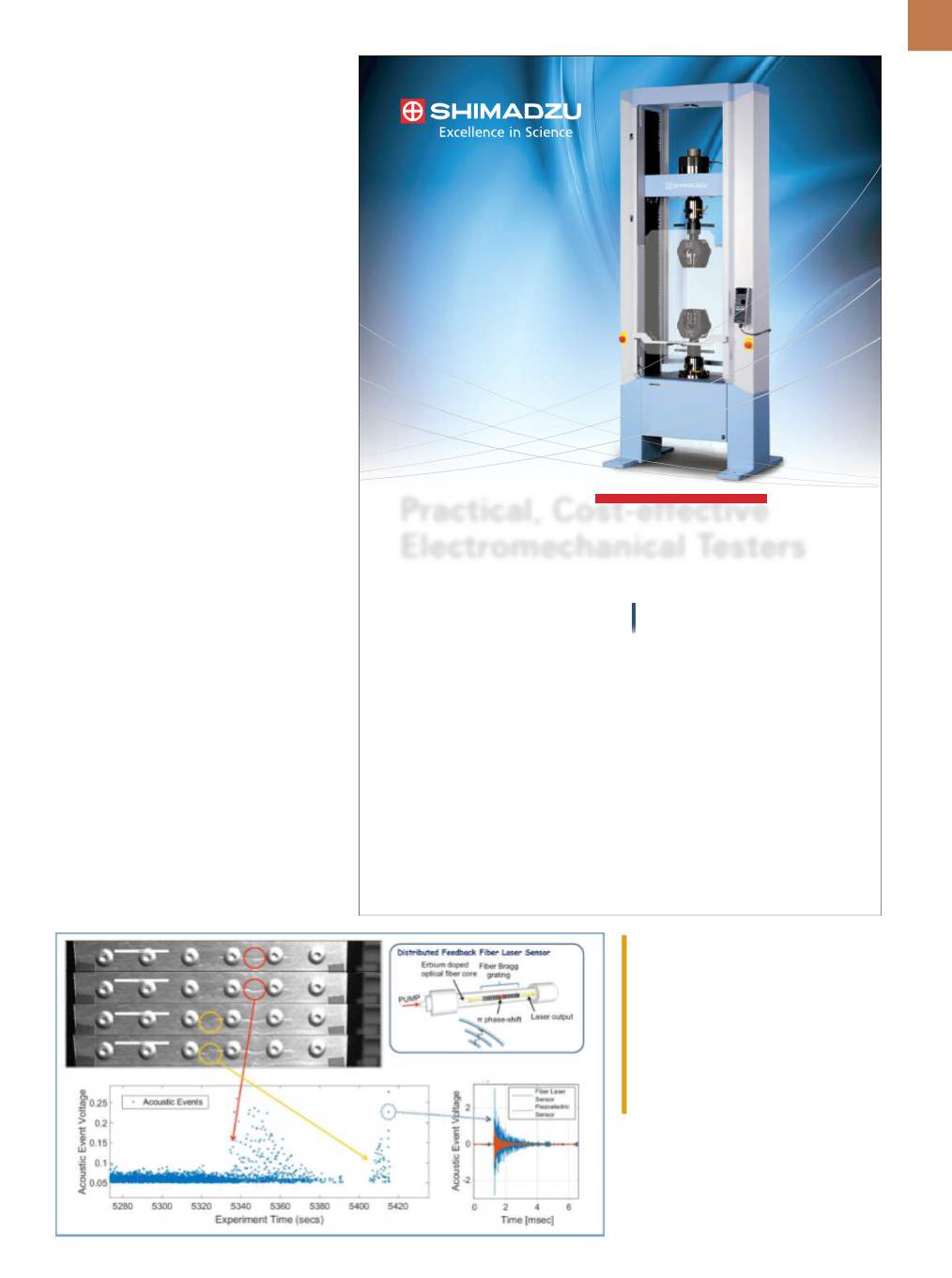

Initiation and growth of cracks between

rivets in a lap joint (top left). A fiber laser

sensor (top right) measures acoustic

emission signals generated by the cracks

and software records them as acoustic

events. A typical event is shown in lower

right plot. Amplitude of the AE events as

a function of time is shown in lower left

plot. Courtesy of NRL.

layers, such as coatings on machine

parts or pharmaceuticals.

mit.edu,

gatech.edu.

FIBER LASER SENSOR LISTENS

FOR FRACTURES

For the first time, scientists at the

U.S. Naval Research Laboratory (NRL),

Washington, used a distributed feed-

back fiber laser acoustic emission sen-

sor to detect acoustic emission from

cracks in riveted lap joints. The sen-

sor, integrated into a shallow groove

in the lap joint, consists of a single

fiber, about the width of a human hair.

Researchers installed the sensors in a

series of riveted aluminum lap joints

and measured acoustic emission over a

bandwidth of 0.5 MHz generated during

a two-hour accelerated fatigue test.

Measurements were also taken with

an equivalent electrical sensor. The

embedded sensors resolved low-level

acoustic events generated by periodic

fretting from the riveted joint in addi-

tion to acoustic emissions from crack

formation. Time-lapse imagery of the

lap joint correlated the observed frac-

ture with the measured signals.

The fiber laser sensor has acous-

tic sensitivity comparable to, or greater

than, that achieved by existing elec-

trical sensors, and its laboratory per-

formance is unmatched by any other

intrinsic optical fiber sensor. It canmea-

sure compromising impacts as well as

cracks, and could integrate with exist-

ing fiber optic strain and temperature

sensing systems. In addition to military

applications, the sensor could be used

for continuous monitoring of buildings

and bridges.

nrl.navy.mil.

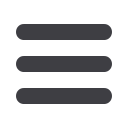

Combining advanced specifications with an affordable, modern design, Shimadzu’s AGS-X Series of floor and tabletop universal testers delivers practical solutions across a wide range of applications. By incorporating multiple control options, load cells with maximum capacities from 1 N to 300 kN, and the utmost in safety considerations, the AGS-X series is the choice for easier, more efficient testing . Shimadzu’s AGS-X Series features: ■ Accurate stress-strain curves with Class 0.5 load cells ■ High-speed data sampling up to 1 msec (1 kHz) ■ Precise stress- and strain-controlled testing ■ Comprehensive safety measures ■ Easy-to-use software with a refined user interface for more efficient, effective testingShimadzu Scientific Instruments Inc., 7102 Riverwood Dr., Columbia, MD 21046, USA

Learn more. Call (800) 477-1227 or visit us online at www.ssi.shimadzu.com/AGSX Practical, Cost-effective Electromechanical Testers In addition, a comprehensive selection of grips, compression plates, jigs, extensometers, and other accessories allow configurations to be tailored to almost any application. Adaptable to Countless Applications