6

MARKET SPOTLIGHT

A D V A N C E D M A T E R I A L S & P R O C E S S E S | O C T O B E R 2 0 1 6

FEEDBACK

MAGNESIUM MARKET SEES STEADY GROWTH

Global growth in the magnesium

market is expected to average 3.4% per

year reaching almost 1.2 Mt per year

by 2020, according to a new report,

“Magnesium Metal: Global Industry,

Markets & Outlook, 12th Edition” from

Roskill Information Services Ltd., Lon-

don. Aluminum alloys and die casting

are predicted to be the fastest grow-

ing markets, both at roughly 4% per

year. However, the main factor affect-

ing magnesium demand will likely be

automobile use, due to both greater

unit consumption and increased vehi-

cle production. Development of mag-

nesium metal with a dense uniform

dispersion of silicon carbide nanopar-

ticles could have significant long-term

impact on demand. In addition, mag-

nesium-ion rechargeable batteries that

have twice the capacity and energy

density of lithium ion batteries could

also spur growth.

In the first quarter of 2016, a

six-year decline in magnesium prices

appears to have leveled out at $2000

per ton, based on production costs in

China where nearly 80% of the world’s

magnesium is produced. As prices

moved below this level at the end of

2015, resistance from producers cou-

pled with firming coal prices and better

COMPOSITE DIE IDEA

I amamechanical engineer with amas-

ter’s degree inmetallurgy, specialized in

welding engineering. Upon retiring several

years ago, I set up a website (www.weld-

ing-advisers.com) to provide open welding

information, consultation, and a free

monthly newsletter. Recently, I applied for

a patent on a newmethod of constructing

a composite die for forging and forming.

I developed the patent to answer, among

others, the following questions:

• Is it possible to build forging or

forming dies in less time than

with

the usual way?

• Is it feasible not to be constrained by

long lead times for tool steel blocks?

• Could a standard, in-stock tool steel

shape be used to make different dies?

• Would simpler and cheaper hardened

tool steels perform adequately for

demanding dies?

I believe my idea would provide some

practical benefits in the cost and time of

building certain classes of dies. However,

I have no real proof, as no hardware was

ever built according to the principles I

developed. I would like to share my idea

with anyone in the industry who might be

interested. A short note describing the es-

sential aspects of the construction of such

dies is available onmy website at www. welding-advisers.com/Composite-Die- Description.html. I am very interested inreceiving comments and feedback from

readers who are curious about my idea.

Elia Levi

www.welding-advisers.com/contact.htmlWe welcome all comments

and suggestions. Send letters to

frances.richards@asminternational.org.

than expected performance in the Chi-

nese economy pushed the price of mag-

nesium up by 11% in April 2016. The

export price for Chinese magnesium is

likely to stay in the $2000 to $2500/ton

range for the remainder of this year.

Global magnesium consumption

is estimated to have grown at an aver-

age annual rate of 1.6% from 2008 to

2015. This was after falling 7% in 2008

and 19% in 2009, and then recovering

by 18% and 9% in the following two

years. Growth was slow in 2012 and

2013, but rose to 8% in 2014 to a peak of

almost 1 Mt. It then fell by 2% in 2015.

Aluminum alloys containing on average

0.8% magnesium are widely used, with

packaging, transport, and construction

comprising the three leading industries

for consumption.

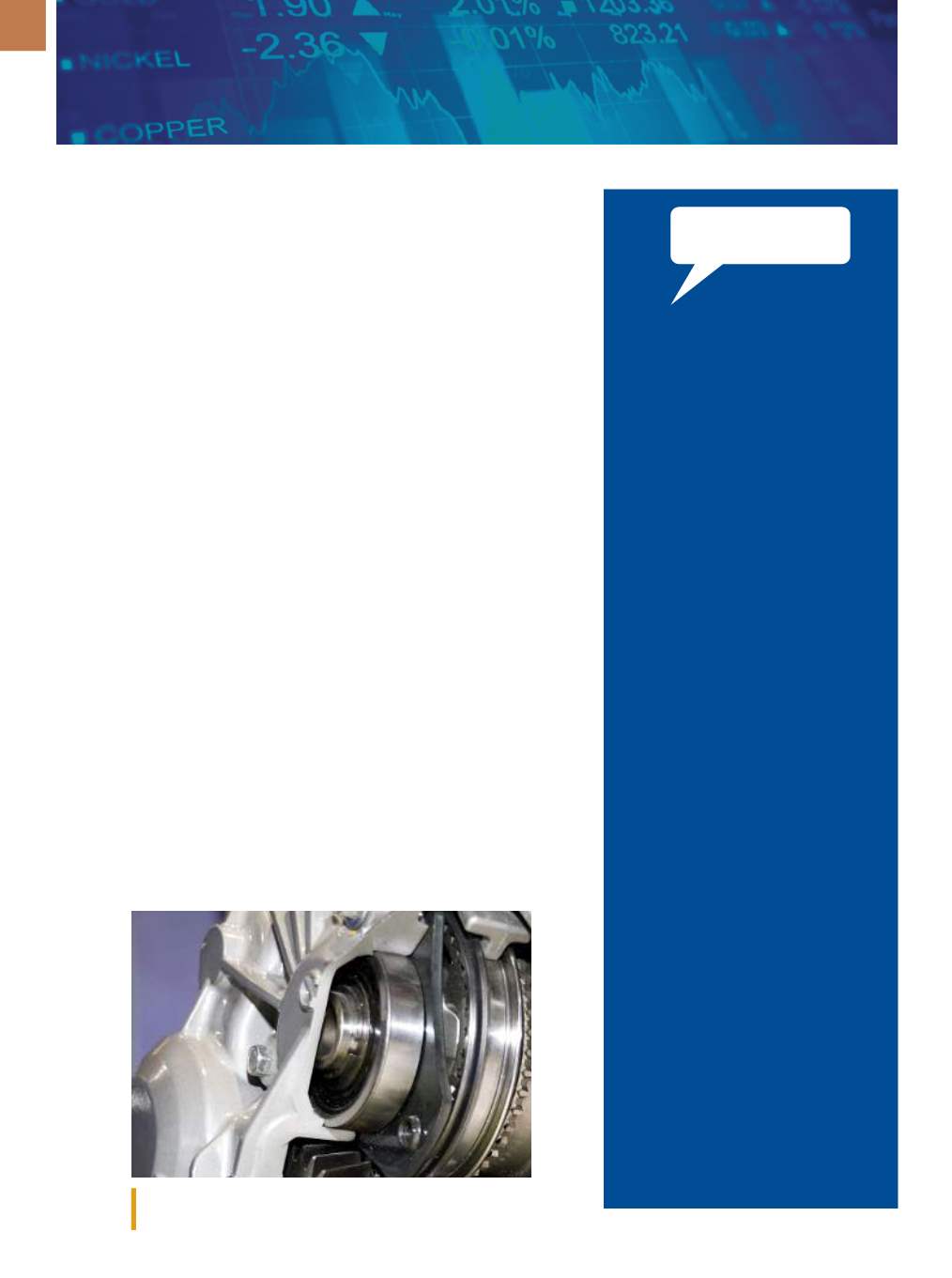

Magnesium castings are used pri-

marily by the automobile industry, but

also in aerospace components, defense

applications, and consumer goods

such as cases for laptops, tablets, and

mobile phones cases. The most widely

used magnesium castings contain more

than 90% Mg commonly alloyed with

aluminum, although some castings

are alloyed with rare earth elements to

impart creep and corrosion resistance.

For more information, visit roskill.com.

Magnesium castings are widely used in automotive and aerospace

applications.