7 4

STRESS RELIEF

A D V A N C E D M A T E R I A L S & P R O C E S S E S | J A N U A R Y 2 0 1 6

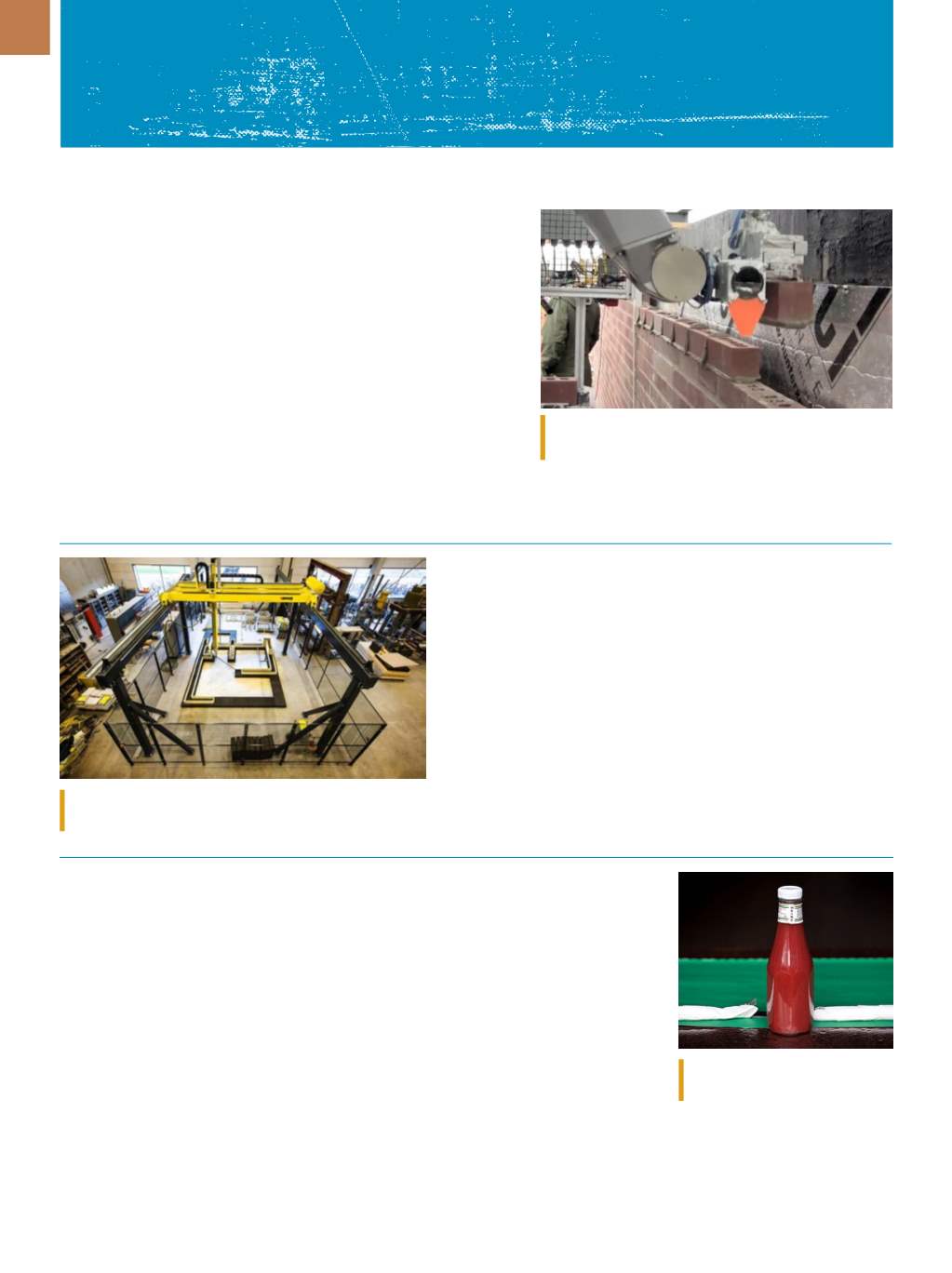

TEAM BUILDING WITH HUMANS AND ROBOTS

Constructionworkers on some sites are getting new, non-union help.

SAM—short for semi-automated mason—is a robotic bricklayer being

used to increase productivity as it works with humans. In this scenario,

the robot is responsible for tasks such as picking up bricks, applying mor-

tar, and brick placement while humans handle more nuanced activities,

like setting up the worksite, laying bricks in tricky areas such as corners,

and handling aesthetic details, like cleaning up excess mortar. SAM can

complete precise and level work while being mounted on a scaffold that

sways slightly in the wind. The robot can correct for differences between

theoretical building specifications and what is actually on site, says Scott

Peters, cofounder of Construction Robotics, Victor, N.Y., which designed

SAM as its debut product. Peters says SAM’s purpose is to leverage human

jobs, not entirely replace them. A human mason can lay 300 to 500 bricks a day, while SAM can lay 800 to 1200. One human plus one

SAM equals the productivity of having four or more masons on the job.

construction-robotics.com.

KETCHUP OFFERS INSIGHTS INTO SOFT MATTER

Soft matter consists of a huge class of materials that can behave either as liquids or sol-

ids depending on circumstances. Soft matter can be found in everything from laptop screens

and advanced batteries to ketchup, mayonnaise, and toothpaste. Cambridge University, UK,

researchers developed new mathematical models to describe why these materials behave the

way they do, which could help improve them for both domestic and high-tech applications.

Professor Michael Cates discovered that mathematical models can explain how soft mate-

rials can suddenly convert from liquid-like to solid-like behavior—through a process resembling

an internal traffic jam. Cates discussed the

jamming

behavior of colloids and dense suspen-

sions. Both are types of soft matter with an internal structure something like tiny ping-pong

balls dispersed in a liquid. Researchers recently created

active

colloids in which the ping-pong

balls are self-propelled, like tiny rockets. When their propulsion is switched on, these particles

form tight clusters, despite having no attractive forces between them.

“The question in this case is what causes the clustering?” wonders Cates. He concluded that each cluster is effectively a sort

of traffic jam. When a dense suspension flows in response to stress, particles must push past each other. As long as the stress is

low, they easily slide past with little friction between them. But when stress is increased, friction between particles also increases.

www.cam.ac.uk.

CONCRETE 3D PRINTING GETS SUPERSIZED

Eindhoven University of Technology, the Netherlands, is using a

concrete printer that enables objects up to 11 × 5 × 4 m to be printed.

The printer looks a bit like an overhead hoisting crane in a production

hall, but instead of a hoisting cable it features a swivel printer head for

concrete. Attached to this via a hose is a concrete mixing and pump

unit. The Dutch company ROHACO built the printer, the first of its kind.

A complete wall can be printed with every required functionality—

fiber-reinforced concrete to make it strong, an active insulation layer to

retain heat, dirt-repelling exterior concrete to keep it clean, and a layer

on the inside to enhance acoustics.

www.tue.nl/en.Top view of concrete printer. Courtesy of Eindhoven

University of Technology/Rien Meulman.

SAM repetitively lays bricks while human masons handle

the finishing touches.

Heinz ketchup. Courtesy of Jeremy

Brooks/Flickr.