iTSSe

TSS

A D V A N C E D M A T E R I A L S & P R O C E S S E S | N O V E M B E R / D E C E M B E R 2 0 1 5

4 8

iTSSe

TSS

6

FEATURE ARTICLE

THERMAL SPRAY ALUMINUM COATINGS

FOR SPLASH ZONE STRUCTURES—PART I

Recent advances in thermal spray techniques enable thermal spray aluminum coatings

to reliably protect offshore structures in splash zones.

Deepashri D. Nage,

L&T Hydrocarbon Engineering Ltd., Mumbai, India

O

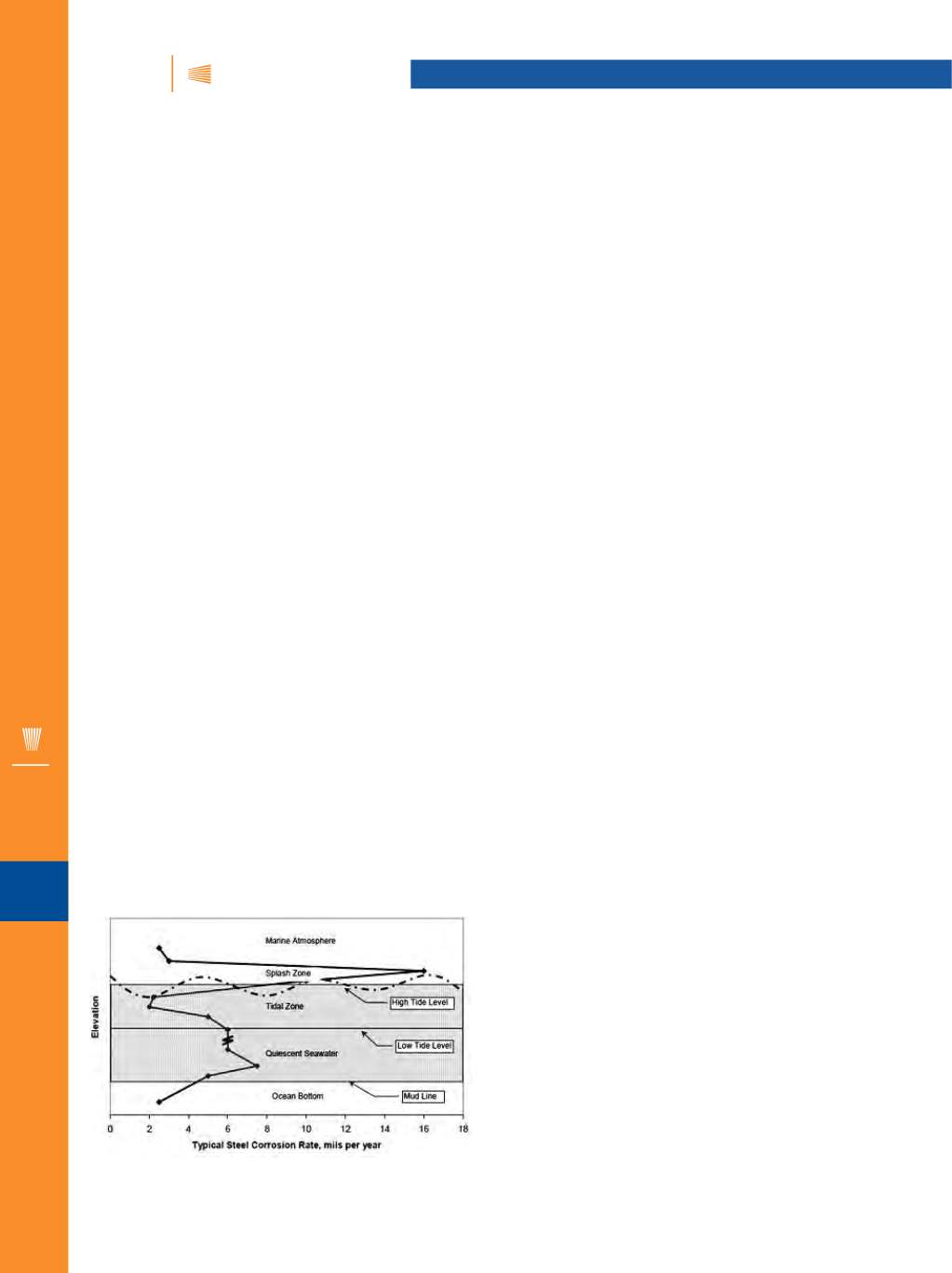

ffshore oil and gas platforms are subjected to hostile,

corrosive marine environments and require continu-

ous operational and preventive maintenance to en-

sure safe operation. These platforms face significant exposure

to seawater immersion, splash zone, and salty, moist air. Steel

corrosion in these environments can be greater than 100 mils

per year

[1]

. The intensity of corrosion of an unprotected steel

structure in seawater varies noticeably relative to the mean

high and low tide level as shown in Fig. 1.

Submerged zones have a corrosion rate as low as

0.015 mm per year due to lack of oxygen and do not usually

require protection. Immersed and tidal zones rely on cathod-

ic protection for corrosion control. However, splash zones

typically range from -3 to 6 m of mean sea level (MSL). This is

the most severely attacked region due to continuous contact

with highly aerated sea water and the erosive effects of spray,

waves, and tidal actions. Cathodic protection in this area is in-

effective due to intermittent contact with seawater.

CORROSION PROTECTION

IN THE SPLASH ZONE

The corrosion rate of unprotected steel in the splash

zone can exceed 30 mils per year. As a result, an exotic pro-

tection method is required. Traditionally, Monel sheathing in

the splash zone was used and a typical system consisted of

vinyl or chlorinated rubber coatings in multiple layers with a

total build of 250–300

μ

m (10–12 mils). Over time, inorganic

zinc silicate primers were incorporated into the systems as

well as epoxy intermediate coats. These systems were used for

several decades with good results, and inorganic zinc/epoxy/

urethane systems are still used today. Current technologies

include use of organic zinc-rich primers, higher build epoxies,

and polysiloxane coatings. Glass flake reinforced epoxies and

polyethylene are also prevalent for abusive conditions with

thicknesses up to 1500

μ

m.

Recently, the oil and gas industry has begun using ther-

mal spray aluminum (TSA) coatings to protect steel structures

in the splash zone. Extensive testing and industry experience

in marine environments indicate that TSA coatings are a long-

term solution for protection of hot risers in submerged, splash

zone, and atmospheric service environments

[1]

. TSA is recom-

mended in NORSOK (M-501-surface preparation and protec-

tive coating) and in NACE RP-0176-2003.

Thermal spray coatings are generally used to hardface

seats and valve balls, refurbish rollers for high temperature

and/or wear resistance, and are usually used in confined ar-

eas. Thermal spray application in open yards on very large

structures is challenging. TSA coatings are one of the most

successful protective coatings for splash zone of offshore

structures, and their performance is well documented by

the American Welding Society (AWS), U.S. Navy, British stan-

dards, Norwegian offshore studies, and The Welding Insti-

tute (TWI).

A recent AWS study evaluated various parameters such

as coating thickness, surface preparation, and sealer coat-

ings in long-term exposures in several environments. Sealed

TSA-coated panels (80

μ

m) at Wrightsville Beach, N.C., ex-

hibited no damage to the underlying steel after 19 years

of exposure

[2]

. In addition, the main result of a study con-

ducted by the U.S. Navy shows successful performance of a

125-micron unsealed TSA coating after 15-years of exposure

and a 100-micron TSA coating after 18.5 years (Port Huen-

eme Harbor, Calif.)

[3]

.

Further, a 1977 British Standard (BS 5493) states that

a sealed TSA will protect steel from corrosion for 20 years or

longer without maintenance in seawater splash-zones

[4]

. It

should be noted, however, that TSA coatings from 1977 are

the same quality as those used today. Based on these studies

and the current scenario of protective coatings, TSA coatings

are considered the most appropriate protective coatings for

the splash zone and have even been used on a project with six

legged jackets.

Fig. 1 —

Steel corrosion rate relative to sea level.