iTSSe

TSS

A D V A N C E D M A T E R I A L S & P R O C E S S E S | N O V E M B E R / D E C E M B E R 2 0 1 5

5 2

iTSSe

TSS

10

JTST

HIGHLIGHTS

The

Journal of Thermal Spray Technolo-

gy

(

JTST

), the official journal of the ASM

Thermal Spray Society, publishes con-

tributions on all aspects—fundamental

and practical—of thermal spray science,

including processes, feedstock manu-

facture, testing, and characterization.

As the primary vehicle for thermal spray

information transfer, its mission is to

synergize the rapidly advancing thermal spray industry and

related industries by presenting research and development ef-

forts leading to advancements in implementable engineering

applications of the technology. Articles from the October and

December issues, as selected by JTST Editor-in-Chief Christian

Moreau, are highlighted here.

The October issue focuses on suspension and solution

thermal spraying. The first four articles highlighted below

are from this issue. The December issue is also a special

issue, featuring the 6th Asian Thermal Spray Conference

(ATSC-6). The last article highlighted below is from that is-

sue. In addition to the print publication,

JTST

is available

online through

springerlink.com. For more information, visit

asminternational.org/tss.“DEMANDS, POTENTIALS, AND ECONOMIC

ASPECTS OF THERMAL SPRAYING WITH

SUSPENSIONS: A CRITICAL REVIEW”

Filofteia-Laura Toma, Annegret Potthoff, Lutz-Michael

Berger, and Christoph Leyens

Advantages of ceramic coatings by using fine powder sus-

pensionas feedstock inAPSandHVOFprocesses includedirect

feeding of fine nano- and submicron-scale particles to avoid

special feedstock powder preparation, the ability to produce

coating thicknesses in the 10-50 µm range, a homogeneous

microstructure with less anisotropy and lower surface rough-

ness compared to conventional coatings, and retention of ini-

tial crystalline phases. This paper discusses the main aspects

of thermal spray with suspensions in order to economically

produce these coatings. The efficiency of the process depends

on availability of suitable additional system components (e.g.,

suspension feeder, injectors), development and handling of

stable suspensions, and high process stability for use at the

industrial scale. There is special focus on the development

and processability of highly concentrated water-based sus-

pensions. While costs and operational safety clearly require

water as the liquid media for preparing suspensions on an

industrial scale, its use is often critically discussed due to the

required higher heat input during spraying compared to alco-

holic suspensions.

“WHAT DO WE KNOW, WHAT ARE

THE CURRENT LIMITATIONS OF

SUSPENSION HVOF SPRAYING?”

A. Killinger, P. Müller, and R. Gadow

Suspension spray has evolved during the past decades

and now is at the threshold of commercial use. Compared to

standard powder spraymethods, mainly DC plasma spray and

high velocity flame spray, it is clear that suspension spray will

not replace these well-established technologies. However, it

can extend them by adding new coating properties. But first,

many issues need to be solved. Suspension interaction with

the hot gas stream is much more complex than in ordinary

powder spray processes. In the case of HVOF, when an axial

is injected into the combustion chamber, it is not possible to

directly observe the liquid flame interaction. This paper dis-

cusses the current status of high velocity suspension flame-

spray including torch concepts, torch configuration in case

of a TopGun system, and different injector concepts and their

influence on suspension atomization. The role of suspensions

regarding their rheological and thermodynamic properties is

examined, mainly given by the solvent type and the solid con-

tent. An overview of different available diagnostic methods

and systems and their respective applicability is provided.

Coating properties are shown and discussed for several oxide

ceramics in respect to their possible applications.

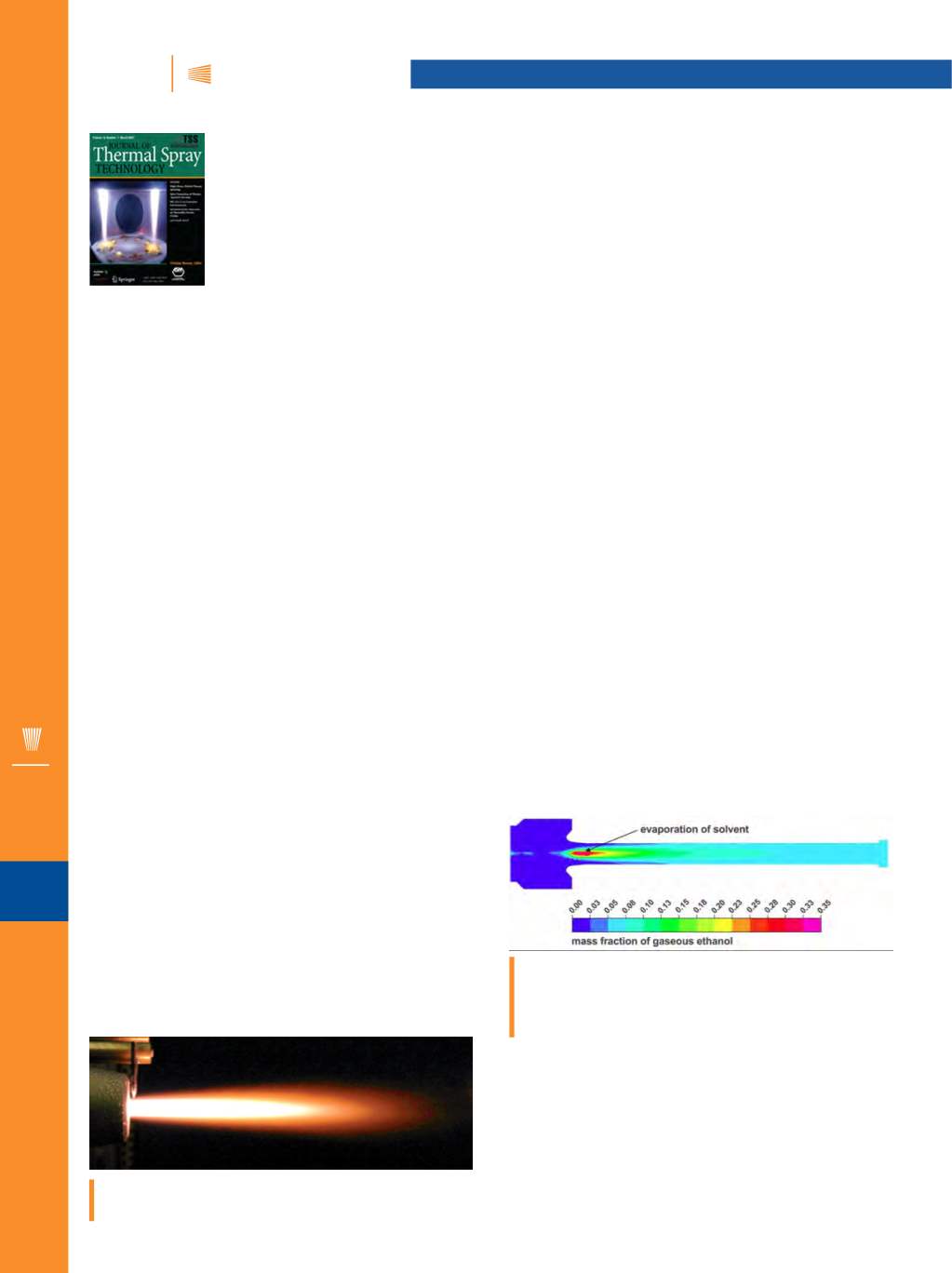

Color of the HVOF flame during spraying of suspensions starting

from an Al

2

O

3

powder with alkali impurities.

CFD simulation of mass fraction contour of gaseous ethanol

in HVSF-spray process using a standard combustion chamber

geometry of a TopGun. Evaporation occurs at the expansion

barrel entrance.

“MICROSTRUCTURAL ANALYSIS OF

COLD-SPRAYED TI-6AL-4V AT THE

MICRO- AND NANO-SCALE”

A.M. Birt, V.K. ChampagneJr.,R.D. SissonJr., andD. Apelian

The microstructure of cold sprayed Ti-6Al-4V is different

than any structure resulting from any other processing tech-

nique. The unique characteristics are derived from the solid