A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

M A R C H

2 0 1 5

4 5

11

TECHNICAL SPOTLIGHT

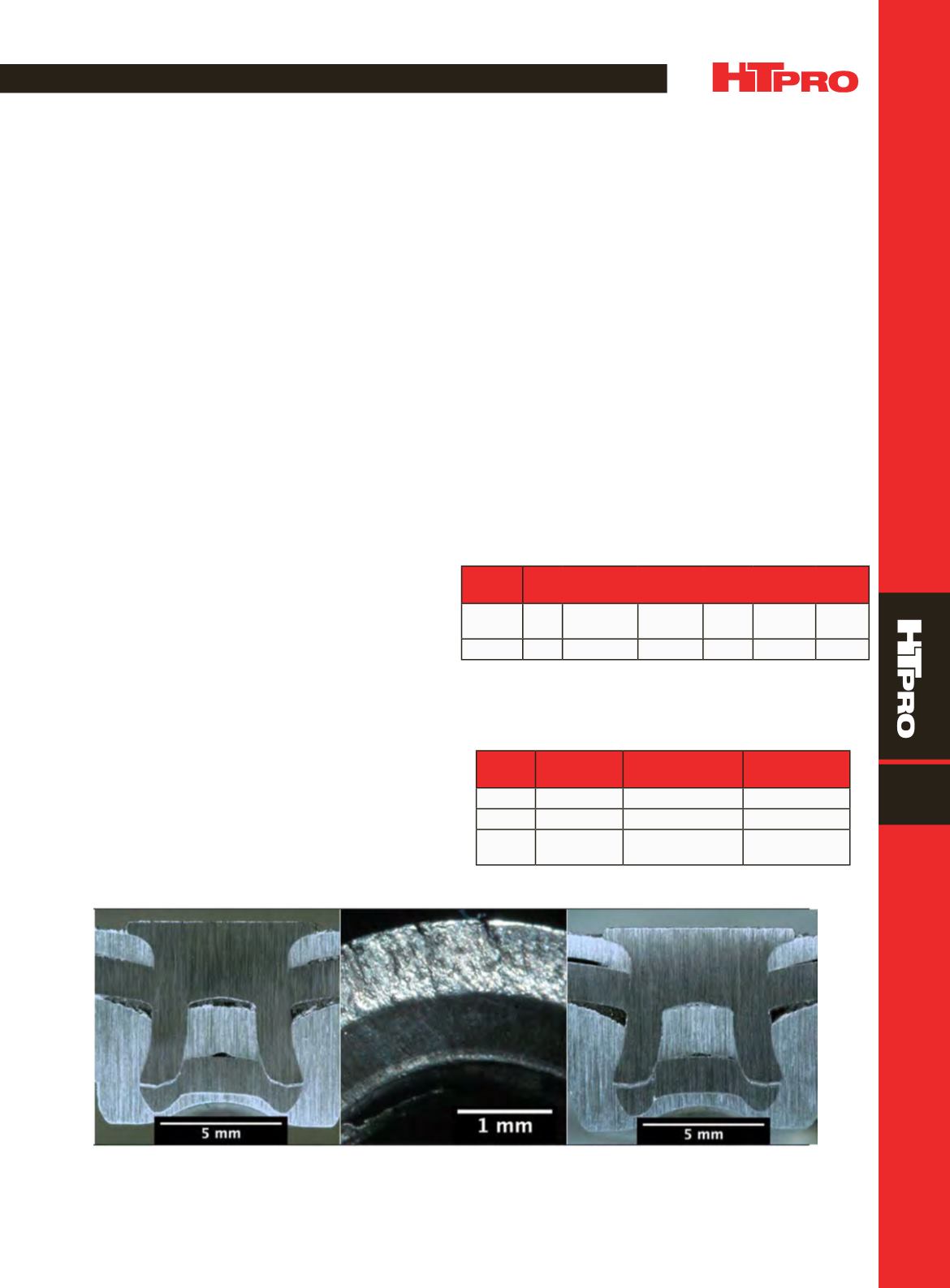

Fig. 2 —

(a) Cross section of an aluminum-press-hardened steel-aluminum joint with a rivet tempered to a high hardness level; (b) bottom

view of rivet extracted from joint shown in (a), which indicates cracking in the rivet tail; and (c) cross section of an aluminum-press-hardened

steel-aluminum joint with a rivet tempered to a lower hardness level, where no rivet tail cracking occurred.

(a)

(b)

(c)

TABLE 1 —CHEMICAL COMPOSITION OF SELECT STEEL RIVETS

Steel

grade

Element, wt%

Fe C Mn Si Cr B

10B37 Bal 0.35–0.41 0.7–0.8 0.1

max 0.2–0.3 0.005

max

4340 Bal

0.41

0.73 0.29 0.84

…

joining press-hardened steel (1500 MPa tensile strength) to

6000 series aluminum. Joining high-strength steel requires a

rivet skirt hard enough to pierce the material, strong enough

to resist compressing and buckling, and ductile enough to

flare outwards at least 0.2 mmwithout cracking.

Thisapplicationrequiressufficientrivetcolumnstrength

andductility toprovide flaring into thebottomsheet to create

a strong interlock. The joint cross section in Fig. 2a shows that

if the rivet hardness is too high without the required ductili-

ty, fractures form on the periphery of the rivet tail. Fractures

are visible in the bottom view of the extracted rivet (Fig. 2b);

joints in which fractures occur in the rivet cannot be used in

automobiles. The cross section of a rivet (Fig. 2c) tempered to

obtain sufficient ductility to accommodate the flare without

forming fractures in the rivet tail shows that tempering also

reduces column strength, which can cause buckling when

piercing press-hardened steel. Development of a rivet ma-

terial that provides greater ductility at the required column

strength would enable the use of SPR technology for a great-

er range of high strength steel-to-aluminum joints.

New rivet materials also could simplify production.

Currently, dozens of rivet and die combinations are required

to join the wide range of different stack material combina-

tions in a vehicle body. A rivet with the necessary ductility

at strength levels that prevent buckling could simplify as-

sembly by reducing the total number of unique rivet and die

combinations and the associated robotic machinery. The

process of reducing the number of different combinations

to reduce cost and complexity is referred to as “

commoniza-

tion

.” In addition, in joints where a slightly longer rivet can be

used, selecting a rivet material with increased ductility could

enable achieving evenmore commonization. In joints where

higher ductility allows using a different rivet hardness, more

commonization benefits are realized by reducing the num-

ber of different rivet hardness levels.

Improved ductility at high rivet hardness would in-

crease possible SPR applications. Fractures on the periphery

of the rivet tail (Fig. 2a) are believed to develop froma tensile

hoop stress at the rivet tail that evolves during flaring. Alter-

native steel alloys and thermal processing techniques are

under investigation to provide improved ductility.

Prototype 4340 alloy steel rivets were evaluated in riv-

eting trials. The chemical composition of the 4340 alloy used

is provided inTable 1. Rivetsweremachined fromwire rodby

Henrob Corp., New Hudson, Mich., and heat treated to vari-

ous hardness levels under laboratory conditions. They were

inserted into a press-hardened steel and 6000 series alumi-

num sheet metal stack (Fig. 2) to evaluate the impact of im-

proved mechanical properties on rivet performance. Figure

3a shows a joint cross section containing a prototype rivet

tempered to a high hardness. Interlock distances for 10B37

rivets and prototype 4340 rivets are shown in Table 2. Initial

TABLE 2—CHARACTERISTICS OF 10B37 FORGED

RIVETSAND 4340 MACHINED PROTOTYPE RIVETS

Steel

grade

Hardness

(HV)

Interlock

distance, mm

Failure

mode

10B37

590

0.47

Tail fracture

10B37

550

0.62

Buckling

4340

595

0.64

None

apparent