FEATURE

A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

M A R C H

2 0 1 5

4 1

7

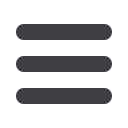

Fig. 1 —

Carbon-steel test blocks with different surface conditions

and emissivities used to determine heating times to temperature.

Fig. 2 —

Carbon-steel test blocks with inserted thermocouples

used to determine the effect of surface condition on times to heat

to temperature in a vacuum furnace.

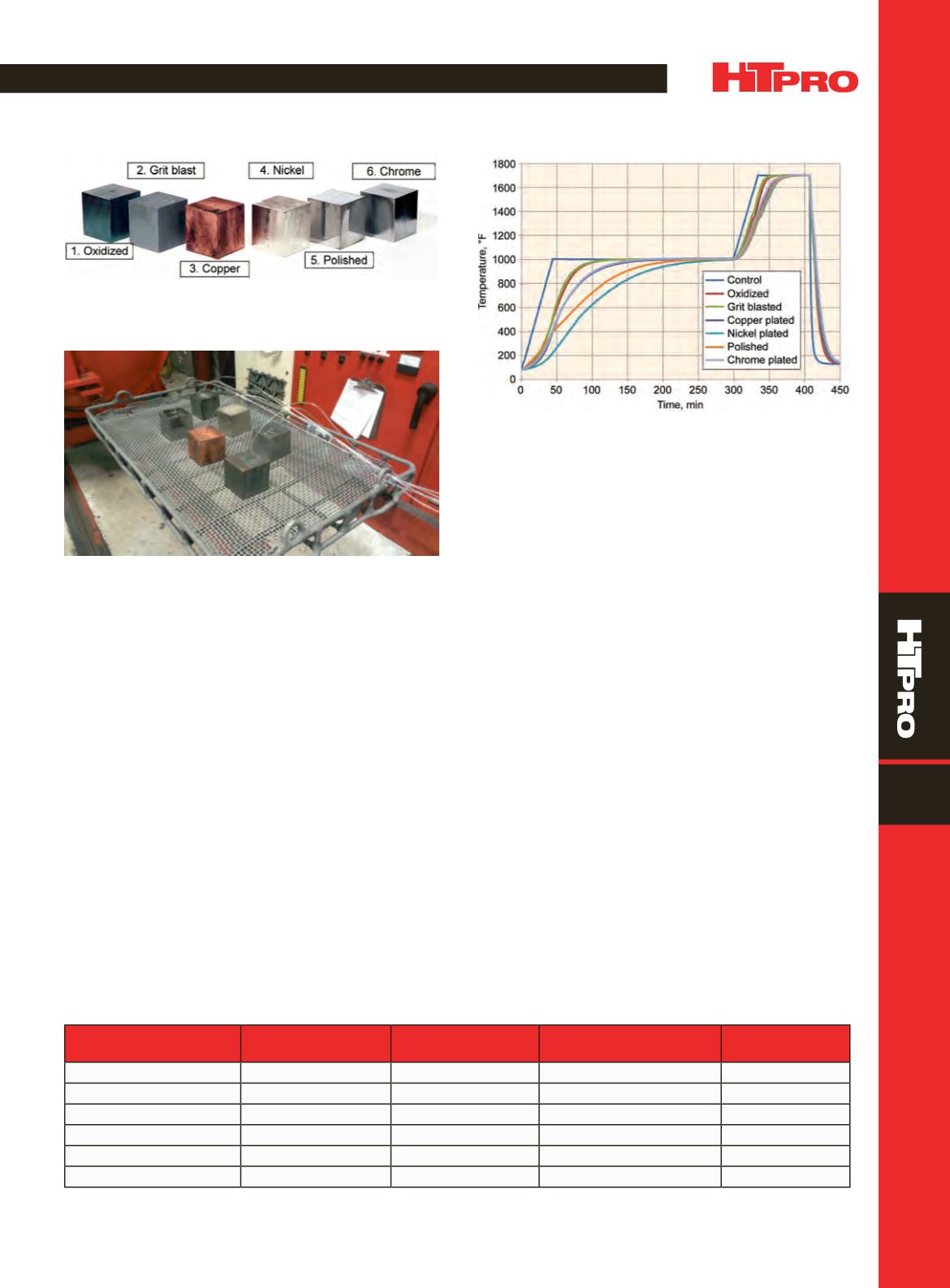

Fig. 3 —

Effect of surface condition and corresponding emissivi-

ties on time to heat carbon-steel test blocks in a vacuum furnace.

TABLE 2— EFFECT OF SURFACE CONDITION AND EMISSIVITY ON TIME

TO HEAT CARBON STEEL TEST BLOCKS IN VACUUM FURNACE(a)

Surface condition

Approximate

emissivity

Heating time to

1000

°

F, min

Heating time from

1000

°

to 1700

°

F, min

Total heating

time, min

Grit blasted

0.75–0.80

111

49

160

Oxidized

0.80–0.95

114

54

168

Chromium plated

0.20–0.40

152

68

220

Copper plated

0.04–0.57

168

68

236

Polished

0.12–0.40

241

74

315

Nickel plated

0.045–0.08

264

75

339

(a) 2.5 in. cubes with different surface conditions

1. Pump furnace down to initial vacuum of less than

1 × 10

-3

torr

2. Heat furnace to 1000

o

F at 15

o

F per minute

3. Hold at 1000

o

F until all blocks are within 10

o

F of set

point and hold 15 minutes

4. Heat furnace to 1700

o

F at 15

o

F per minute

5. Hold at 1700

o

F until all blocks are within 10

o

F of set

point and hold 15 minutes

6. Cool load and furnace back to unloading temperature

Figure 3 shows the plots of thermocouple readings as a

function of time. The curves illustrate the important role that

emissivity or absorptivity plays relative to heating materials

in a vacuum furnace. Table 2 shows the effects of emissivity

and surface condition on heating time for the same part size.

Carbon steel blocks of the same size can take up to twice the

time to heat to temperature, depending on surface condition.

The approximate emissivity value of the surface condition is

closely reflected in the relative heating times. This informa-

tion enables predicting relative heating rates for different sur-

face conditions and their respective emissivity values (Fig. 4).

EFFECTS OF TEST BLOCK MASS

AND CROSS SECTION

A second series of test blocks was used to further

demonstrate the importance of correct cross section and

surface condition in thermocouple test blocks. Pairs of three

different block sizes (1, 1.75, and 2.5 in. cube) consisted of

polished and oxidized blocks.

Dummy blocks were loaded into a workbasket similar

to that described above (Fig. 5), and the workbasket was

placed into the furnace. Process cycle steps were as follows:

1. Pump furnace down to initial vacuum of less than

1 × 10

-3

torr

2. Heat furnace to 1150

o

F at 15

o

F per minute

3. Hold at 1150

o

F until all blocks are within 10

o

F of set

point and hold 15 minutes