FEATURE

A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A R C H 2 0 1 5

4 2

8

4. Heat furnace to 1700

o

F at 15

o

F per minute

5. Hold at 1700

o

F until all blocks are within 10

o

F of set

point and hold 15 minutes

6. Cool load and furnace back to unloading temperature

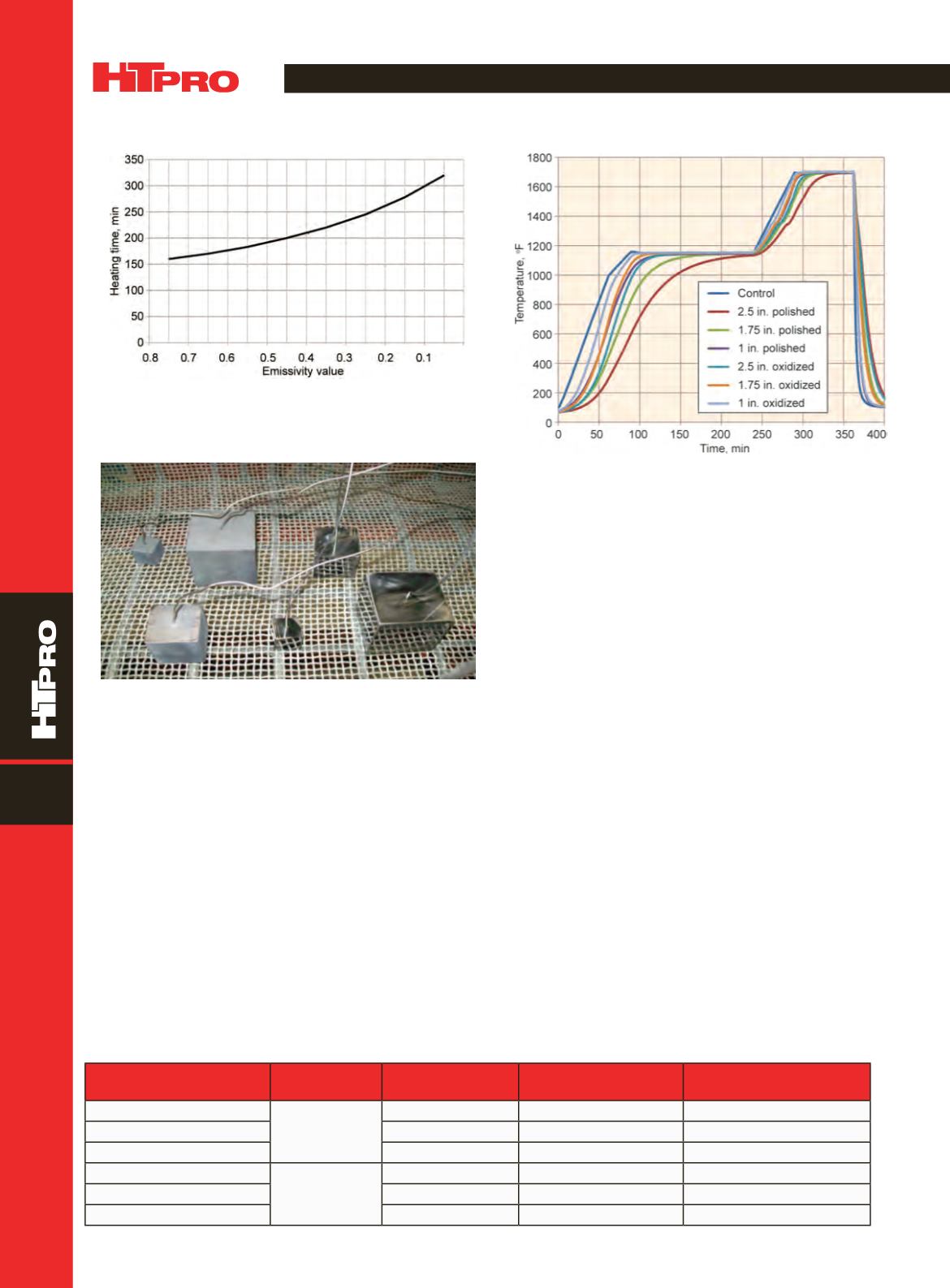

Figure 6 shows the plots of thermocouple readings as

a function of time, and Table 3 shows the effects of size and

surface condition for the same emissivity. This further em-

phasizes that consideration must be given to thermocouple

test blocks regarding mass, cross section, and surface condi-

tion. For example, a 1 in. cube of polished carbon steel took

longer to heat to temperature than a 2.5 in. cube of oxidized

carbon steel.

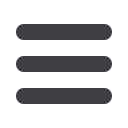

Fig. 4 —

Projected heating times based on material surface

condition and corresponding emissivity.

Fig. 5 —

Carbon-steel test blocks with thermocouples used to

determine the effects of size and surface condition on times to

heat to temperature in a vacuum furnace.

TABLE 3—EFFECT OF SIZE AND SURFACE CONDITION ON TIME TO HEAT CARBON STEEL TEST BLOCKS IN VACUUM FURNACE

Test block size/surface

condition

Approximate

emissivity

Heating time to

1000

°

F, min

Heating time from

1000

°

to 1700

°

F, min Total heating time, min

1 in. cube/ oxidized

0.80–0.95

68

39

107

1.75 in. cube/ oxidized

79

46

125

2.5 in. cube/ oxidized

98

48

146

1 in. cube/polished

0.12–0.40

100

53

153

1.75 in. cube/polished

135

55

180

2.5 in. cube/polished

166

73

239

Fig. 6 —

Effect of size and surface condition on time to heat

carbon-steel test blocks in a vacuum furnace.

The following conclusions are derived from this study:

•

Radiation heating of materials in a vacuum furnace

is greatly affected by the material’s emissivity and

absorptivity

•

Bright, polished materials take much longer to heat

than materials with dull, dark surfaces

•

Material surface roughness affects heating rate,

because rough surfaces heat faster than smooth,

reflective surfaces

•

When using thermocouple blocks to simulate actual

load parts, the material and cross section must not

only be similar, but also the surface condition (color

and texture) must be the same

•

Thermocouple test blocks should be periodically

reconditioned to maintain proper surface smoothness

and appearance

•

A workload with a particular surface condition

compared with a workload of the same material with

another surface condition could take up to twice as

long to reach the desired temperature

For more information:

Reàl Fradette is senior consultant,

Solar Atmospheres Inc., 1969 Clearview Rd., Souderton, PA

18964,

rfradette@solaratm.com,

solaratm.com.